2.Selection of high-quality tungsten steel

High efficiency, high wear resistance

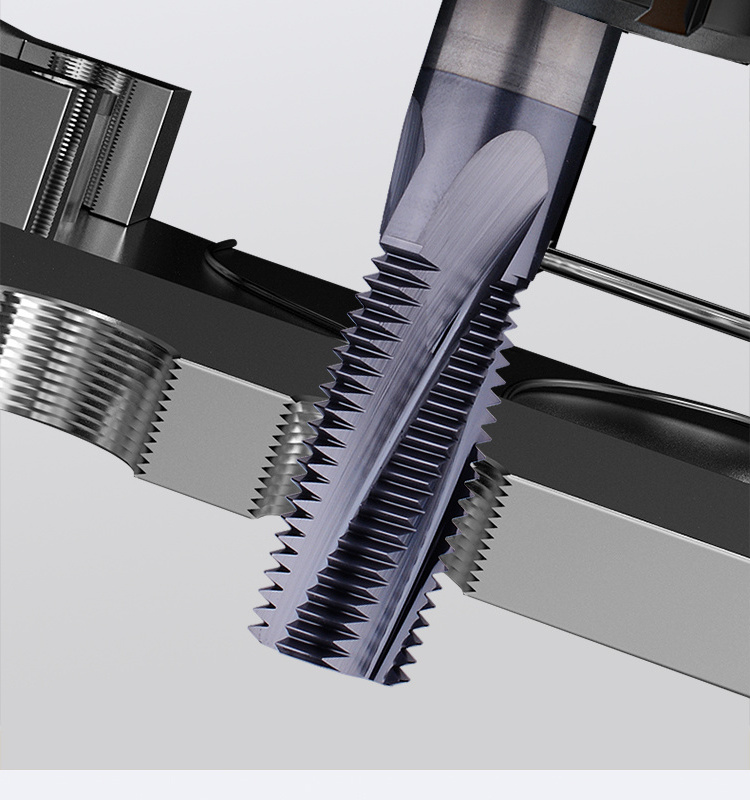

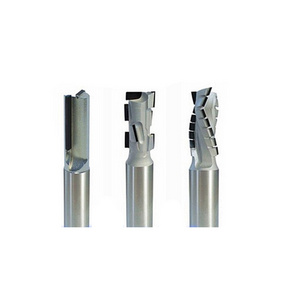

3.New cutting edge design

Groove polishing treatment is more conducive to chip removal

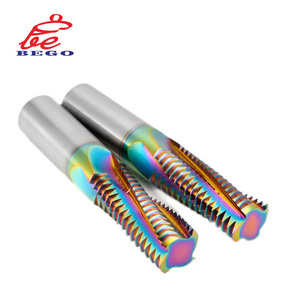

4.Coating process

Excellent wear resistance and effective heat insulation

5.

Chip removal design is more efficient

Inclined multi-row 4 large chip flutes

6.Suitable for a variety of materials

Application: aluminum, copper, cast iron, stainless steel, alloy steel, tool steel, titanium alloy, heat treatment die steel,etc.