- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HKAA

-

Model Number:

-

TT-728

-

Product name:

-

Professional Precision Cnc Machining Parts

-

Process:

-

CNC Turning Milling

-

Surface treatment:

-

Customer's Request

-

Service:

-

One Stop Service. Machining-assembly

-

Equipment:

-

3/4/5 Axis CNC Machining Center

-

Application:

-

Medical/Industrial Equipment/Furniture decoration

-

Color:

-

Customized Color

-

Keyword:

-

standoff spacer

-

Certification:

-

AS9100,IATF16949,ISO13485

Quick Details

-

Material:

-

ZINC, ALLOY, Titanium, Stainless steel, Customized

-

Type:

-

standoff spacer

-

Size:

-

Customized

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HKAA

-

Model Number:

-

TT-728

-

Product name:

-

Professional Precision Cnc Machining Parts

-

Process:

-

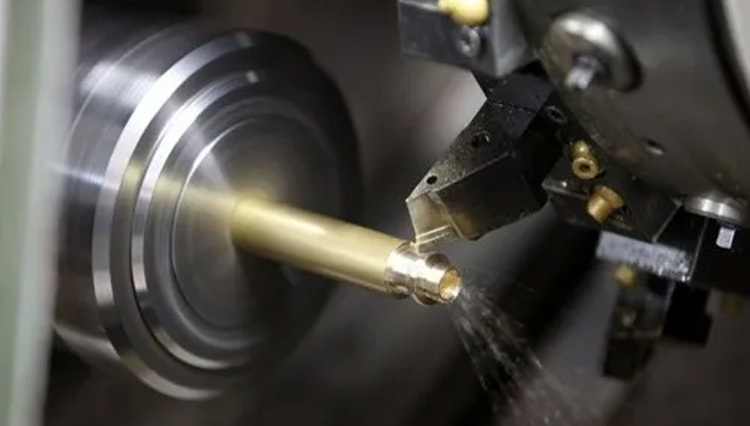

CNC Turning Milling

-

Surface treatment:

-

Customer's Request

-

Service:

-

One Stop Service. Machining-assembly

-

Equipment:

-

3/4/5 Axis CNC Machining Center

-

Application:

-

Medical/Industrial Equipment/Furniture decoration

-

Color:

-

Customized Color

-

Keyword:

-

standoff spacer

-

Certification:

-

AS9100,IATF16949,ISO13485

Products Description

|

Product Item

|

CNC Custom M6 M8 M10 M12 Aluminum alloy shaft sleeve aluminum stainless steel round Standoff Spacer Screw Nuts

|

|

|

|

|

Materials

|

Metal: Aluminum , Copper , Brass , Steel, Stainless Steel, Titanium and etc.

Plastic: ABS, POM, PP, PU, PC,PA66, PMMA, PVC, PVE,Nylon and etc.

|

|

|

|

|

File Formats

|

STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT

|

|

|

|

|

Service

|

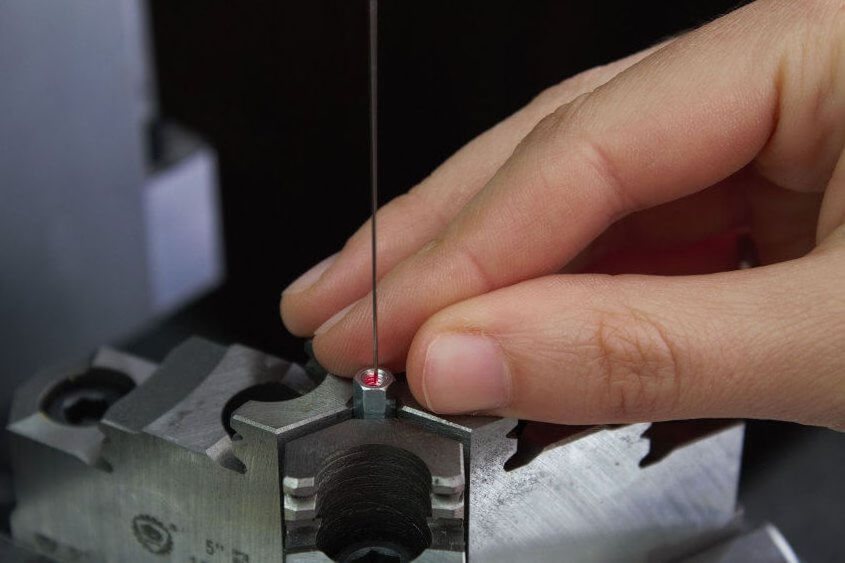

CNC Milling, CNC Turning, Wire EDM Cutting, 3D Printing,Vacuum Casting,Reaction Injection Molding, Plastic CNC Machining, Laser,Cutting, Stamping Parts, Bending Parts

|

|

|

|

|

Our service

|

SWISS MACHINING; DEBURRING; LATHE/TURNING; 5 Axis; MICROMACHINING

|

|

|

|

|

Surface treatment

|

Anodizing, Sandblasting, Metal Plating, Polishing, Painting, Powder coating, Brushing ,Silk-screen , Laser Engraving etc.

|

|

|

|

Standoff Spacer

Size:

M2,M2.5,M3,M4 or customized

We place high demands on the material, manufacturing method and stress on the material during the actual manufacturing process.

For this purpose, we utilize our high-tech devices that we are continually innovating.

Contact us. In order to quote you as soon as possible,we need the following information:

1.Detailed drawings (format:CAD/PDF/DWG/DXF/DXW/IGES/STEP etc.)

2.Material

3.Quantity

4.Surface treatment

5.Any special pacaking or other requirement

We can sign NDA before you send the drawing.

If you need a sample,

we will charge for it,

but we will return it back in mass production.

What we can produce is

Manufacturing Technique

Hot Searches