- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

160

-

Length:

-

14400, 7660, 7200, 3600mm

-

Working Temperature:

-

1300°C

-

Fiber Diameter:

-

2-5um

-

Shrinkage (1800 ℉, 3h):

-

≤-3%

-

Thermal Conductivity:

-

0.09-0.20w/m.k(400-1000°C)

-

Model Number:

-

KT-CFB

-

Brand Name:

-

KAITE

-

Place of Origin:

-

Guangxi, China

-

Raw material:

-

Ceramic Fiber Bulk

Quick Details

-

Thickness:

-

10, 20, 25, 30, 40, 50mm

-

Width:

-

600, 610, 1220mm

-

Chemical Composition:

-

AL2O3+SiO2+ZrO2

-

Ultimate Strength (≥ MPa):

-

0.04

-

Density (kg/m³ ):

-

160

-

Length:

-

14400, 7660, 7200, 3600mm

-

Working Temperature:

-

1300°C

-

Fiber Diameter:

-

2-5um

-

Shrinkage (1800 ℉, 3h):

-

≤-3%

-

Thermal Conductivity:

-

0.09-0.20w/m.k(400-1000°C)

-

Model Number:

-

KT-CFB

-

Brand Name:

-

KAITE

-

Place of Origin:

-

Guangxi, China

-

Raw material:

-

Ceramic Fiber Bulk

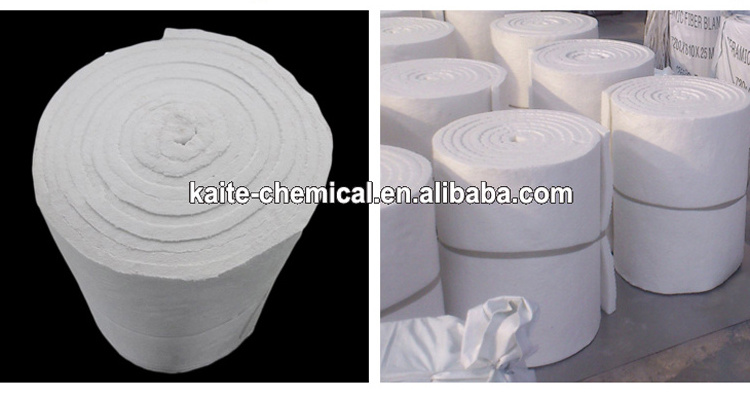

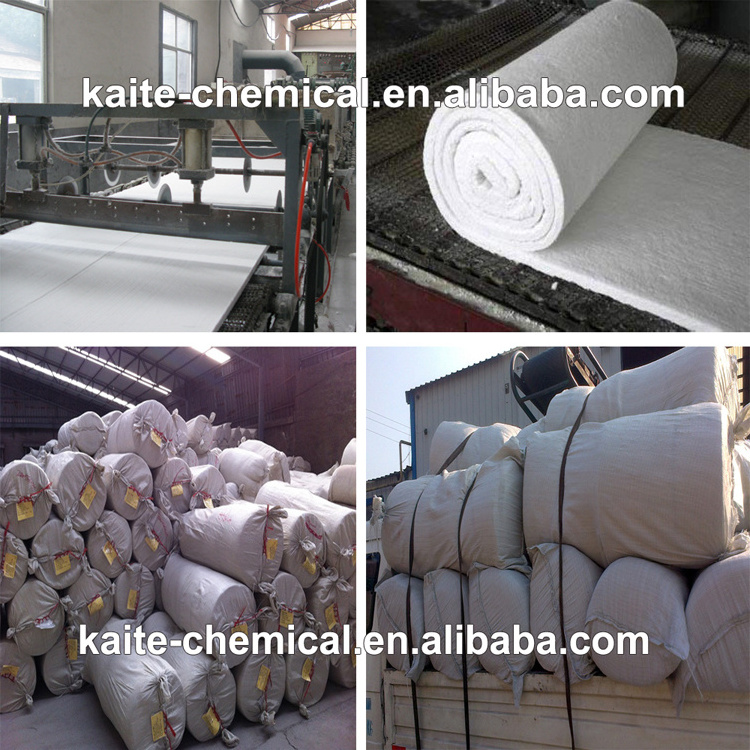

Ceramic fiber blanket is made of special ceramic long-fiber that is produced by the melting of very pure raw materials in double surface meeting process without binders and with good stability in a large range of temperature, the process of double surface needing increase interweaving and tensile strength. Its unique fiber layup and needling process provide Sino shine Ceramic fiber blanket with outstanding consistency, handling strength and resiliency at elevated temperatures.

Product Features

1. Low thermal conductivity, low thermal capacity.

2. Excellent Chemical Stability and Thermal Stability.

3. Excellent tensile strength.

4. Good Sound-absorbing performance, heat insulation and fire protection.

5. Low Thermal shrinkage, good flexibility.

6. Resistance to erosion, long service life.

1. Ceramic industry: Kiln car insulation and seal, continues and batch kiln.

2. Steel industry: Heat treating and annealing furnace, furnace lining and seals, reheating furnace and ladle covers, furnace hot face repairs, soaking hit covers and repairs.

3. Refining and petrochemical: reformer and pyrolisislining, tube seals, gaskets and expansion joints, high temperature pipe, duct and turbine insulation. Crude oil heater lining.

4. Power generation: Boiler insulation, expansion seals and covers insulation.

5. Others: insulation of commercial dryers and ovens, refractory materials, glass furnace insulation, fire protection.

|

Item |

Common Grade |

Standard Grade |

High Pure Grade |

High Alumina Grade |

Zirconium Grade |

|

Color |

White |

Pure white |

Pure white |

Pure white |

Pure white |

|

Classification temp. ( °C) |

1100 |

1260 |

1260 |

1400 |

1430 |

|

Use temp. ( °C) |

950 |

1000 |

1100 |

1200 |

1350 |

|

Theoretical density (Kg/m 3 ) |

64/96/128 |

64/96/128 |

64/96/128 |

96/128/160 |

96/128/160 |

|

Shrinkage on heating (%) |

950°C×24h ≤-3 |

1000°C×24h ≤-3 |

1100°C×24h ≤-3 |

1200°C×24h ≤-3 |

1350°C×24h ≤-3 |

|

Tensile Strength (MPa) |

0.04 |

0.04 |

0.04 |

0.04 |

0.04 |

|

Thermal conductivity (w/m.k) (Physical volume density 128 Kgs/m 3 ) |

0.09(400

°C

)

|

0.09(400

°C

)

|

0.09(400 °C )

0.16(800

°C

)

|

0.12(600

°C

)

|

0.16(800

°C

)

|

|

AL 2 O 3 |

44% |

46% |

47-49% |

52-55% |

39-40% |

|

AL 2 O 3 + SiO 2 |

96% |

97% |

99% |

99% |

82-84% |

|

ZrO 2 |

- |

- |

- |

- |

15-17% |

|

AL 2 O 3 +SiO 2 +ZrO 2 |

- |

- |

- |

- |

99% |

|

Fe 2 O 3 |

≤1.2% |

≤1.0% |

≤0.2% |

≤0.2% |

≤0.2% |

|

Na 2 O+K 2 O |

≤0.5% |

≤0.5% |

≤0.2% |

≤0.2% |

≤0.2% |

|

Item |

Dimensions |

|

Length |

14400mm, 7660mm, 7200mm, 3600mm |

|

Width |

600mm, 610mm, 1220mm |

|

Thickness |

10mm , 20mm, 25mm, 30mm, 40mm, 50mm |

|

Density |

64 kg/m 3 , 96 kg/m 3 ,128 kg/m 3 , 160kg/m 3 |