- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380/220V

-

Rated Power:

-

24

-

Weight (KG):

-

12000 KG

-

Marketing Type:

-

New Product

-

Warranty of core components:

-

24 months

-

Color:

-

Customizable

-

Product name:

-

plasma metal cutting machine

-

Certification:

-

CE ISO

-

Weight:

-

1200kg

-

Dimension(L*W*H):

-

3000*1550*1000

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Reducer:

-

Precision planetary reducer

-

Power:

-

`63-200A

-

Nesting software:

-

Starcam

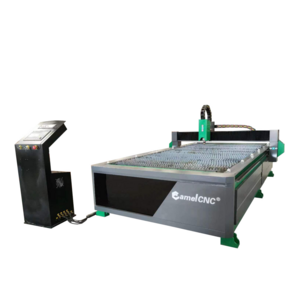

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Rbqlty

-

Model Number:

-

RBT-1530

-

Voltage:

-

380/220V

-

Rated Power:

-

24

-

Weight (KG):

-

12000 KG

-

Marketing Type:

-

New Product

-

Warranty of core components:

-

24 months

-

Color:

-

Customizable

-

Product name:

-

plasma metal cutting machine

-

Certification:

-

CE ISO

-

Weight:

-

1200kg

-

Dimension(L*W*H):

-

3000*1550*1000

-

Cutting material:

-

Metal Stainless Steel Carbon Steel Aluminum

-

Reducer:

-

Precision planetary reducer

-

Power:

-

`63-200A

-

Nesting software:

-

Starcam

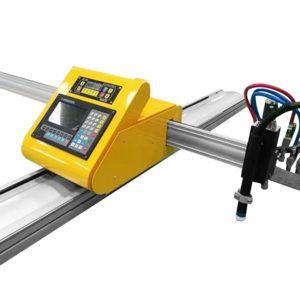

RBT-1530 price for sheet plasma cutting machine

What is plasma?

plasma is the fourth state of matter. We commonly think of matter having three states: a solid, a liquid, and a gas. Matter changes from one state to the other through the introduction of energy, such as heat. For example, water will change from a solid (ice) to its liquid state when a certain amount of heat is applied. If the heat levels are increased, it will change again from a liquid to a gas (steam). Now, if the heat levels increase again, the gases that make up the steam will become ionized and electrically conductive, becoming plasma. A plasma cutter will use this electrically conductive gas to transfer energy from a power supply to any conductive material, resulting in a cleaner, faster cutting process than with oxyfuel.

The plasma arc formation begins when a gas such as oxygen, nitrogen, argon, or even shop air is forced through a small nozzle orifice inside the torch. An electric arc generated from the external power supply is then introduced to this high pressured gas flow, resulting in what is commonly referred to as a “plasma jet”. The plasma jet immediately reaches temperatures up to 40,000° F, quickly piercing through the work piece and blowing away the molten material.

Plasma system components

Power supply -- The plasma power supply converts single or three phase AC line voltage into a smooth, constant DC voltage ranging from 200 to 400VDC. This DC voltage is responsible for maintaining the plasma arc throughout the cut. It also regulates the current output required based on the material type and thickness being processed.

Arc Starting Console – The ASC circuit produces an AC voltage of approximately 5,000 VAC at 2 MHz which produces the spark inside of the plasma torch to create the plasma arc.

Plasma torch – The function of the plasma torch is to provide proper alignment and cooling of the consumables. The main consumable parts required for plasma arc generation are the electrode, swirl ring, and nozzle. An additional shielding cap may be used to further improve cut quality, and all the parts are held together by inner and outer retaining caps.

1.The user doesn’t need to make another plasma cutting machine platform,

longitudinal pipe drag chain bracket,etc.,Saving the expensive fee of the other production cutting platform for users, simplifying the cutting installation work, saving a lot of installation debugging time."

2.Desktop gantry structure,the use bilateral drive,inertia small ,stable operation.

3.Suitable for medium and thin non-ferrous metal plate,stainless steel plate and carbon

steel sheet of automatic cutting down material,It can cuts kinds of the metal plate to any shapes."

4.The use of automatic arc pressure adjustment and dedicated CNC system,powerful,

easy to operate personnel training,high penetration rate. "

Our plasma cutting machine features:

1,We set the

automatic high arc pressure adjusting device

: when the plate shape changes a little during processing, the spearhead will adjust itself to avoid damage of the plate.

2, We set

collision-prevention device

to protect the spearhead from damage when it is suddenly power off.

3, We do

fine grinding processing

to all the contact surface to make sure they joint closely.

4, A set of

SigmaNest (for free)

will send together with the machine to save the material for you.

Plasma cutting machine technical data:

Electric system---Schneider or Simens

We believe that details determines success!

Jiaoda 2500 CNC control system, Hypertherm Supply

Head protection device, to protect the machine from damage

Plasma power--Domestic HUAYUAN

1, Using soft-switching technology

2,Function:help rapidly rising of current

3,Air pressure,water pressure sensor

4,High efficiency and low energy consumption

Plasma power--USA Thermadyne

1 ,A POWERFUL OF 80% DUTY CYCLE

2,Maximum life parts

3,Increased productivity

4,Water mist secondary(WMS) for low cost,high quality cutting on non-ferrous

Plasma power--USA Hypertherm

1,Super cutting speed

2,NEW HDI thin stainless steel technology

3,Maximized productivity

4,Minimized operating cost& best reliability

FAQ

Q: How to choose a laser cutting machine?

A: Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

Q: Where is your factory? How can I get there?

A: You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad,

warmly welcome to visit us!

Q: How do you ensure quality in the factory?

A: Quality culture always attach great importance to quality control from the beginning to the end. Our factory has obtained

ISO, CE certification.

Q: How can I pay?

A: You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

Q: How long to produce?

A: Delivery time:15-35 days.