- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or customized

-

Power:

-

45KW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product:

-

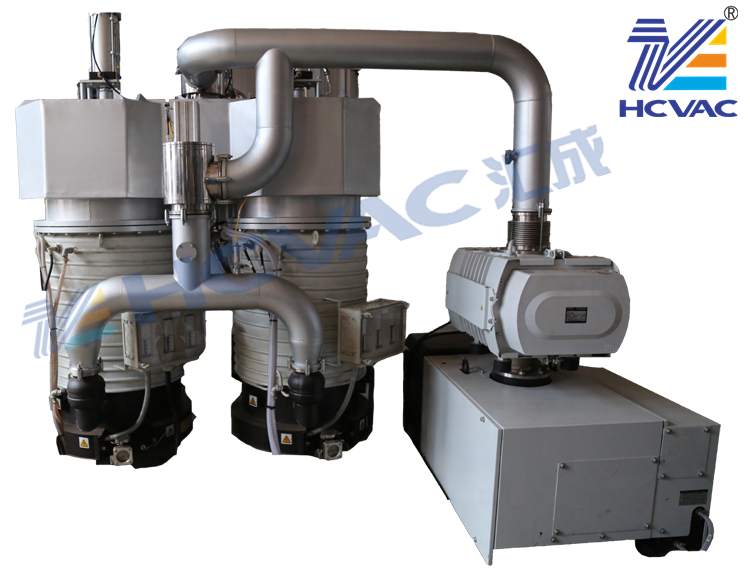

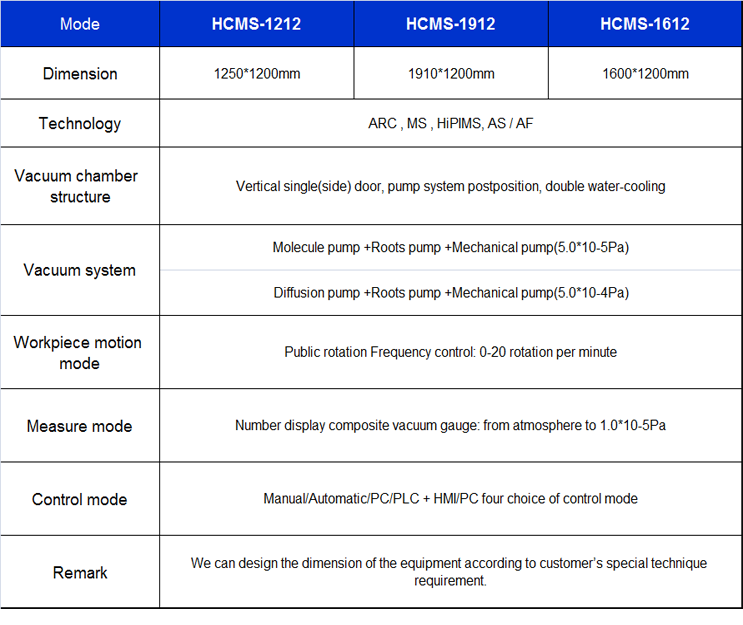

Magnetron sputtering vacuum coating Machine

-

business type:

-

manufacturer/supplier

-

technology:

-

ion coating+sputtering coating

-

structure:

-

vertical,single doors

-

control system:

-

manual,automatic all-in-one

-

operating system:

-

PLC control+touching screen

-

size:

-

customizing

-

chamber material:

-

stainless steel

-

color:

-

gold,rosegold,silver,black,blue,coffee ect

Quick Details

-

Machine Type:

-

PVD vacuum coating machine, Coating Equipment, vacuum coating machine

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HCVAC

-

Voltage:

-

380V or customized

-

Power:

-

45KW

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product:

-

Magnetron sputtering vacuum coating Machine

-

business type:

-

manufacturer/supplier

-

technology:

-

ion coating+sputtering coating

-

structure:

-

vertical,single doors

-

control system:

-

manual,automatic all-in-one

-

operating system:

-

PLC control+touching screen

-

size:

-

customizing

-

chamber material:

-

stainless steel

-

color:

-

gold,rosegold,silver,black,blue,coffee ect

Product Description

Magnetron Sputtering Coating

Plasma coating

Magnetron sputtering is a plasma coating process whereby sputtering material is ejected due to bombardment of ions to the target surface. The vacuum chamber of the PVD coating machine is filled with an inert gas, such as argon. By applying a high voltage, a glow discharge is created, resulting in acceleration of ions to the target surface and a plasma coating. The argon-ions will eject sputtering materials from the target surface (sputtering), resulting in a sputtered coating layer on the products in front of the target. Magnetron sputtering technology is characterized by:

* A water-cooled target, so little radiation heat is generated

* Almost any metallic target material can be sputtered without decomposition

* Non-conductive materials can be sputtered by using radio frequency (RF)

or medium frequency (MF) power

* Oxide coatings can be sputtered (reactive sputtering)

* Excellent layer uniformity

* Very smooth sputtered coatings (no droplets)

* Cathodes (of up to 2 meter long) can be put in any position, therefore high

flexibility of sputtering equipment design

Plasma coating

Magnetron sputtering is a plasma coating process whereby sputtering material is ejected due to bombardment of ions to the target surface. The vacuum chamber of the PVD coating machine is filled with an inert gas, such as argon. By applying a high voltage, a glow discharge is created, resulting in acceleration of ions to the target surface and a plasma coating. The argon-ions will eject sputtering materials from the target surface (sputtering), resulting in a sputtered coating layer on the products in front of the target. Magnetron sputtering technology is characterized by:

* A water-cooled target, so little radiation heat is generated

* Almost any metallic target material can be sputtered without decomposition

* Non-conductive materials can be sputtered by using radio frequency (RF)

or medium frequency (MF) power

* Oxide coatings can be sputtered (reactive sputtering)

* Excellent layer uniformity

* Very smooth sputtered coatings (no droplets)

* Cathodes (of up to 2 meter long) can be put in any position, therefore high

flexibility of sputtering equipment design

Features

* High realibility

* High productivity and flexibility

* Consistently brilliant end product quality

* Full automation capability

* Excellent coating flexibility

* Long lifetime and fast target exchange

* Flexible system configuration

* High speed coating and best PVD homogeneity

HCVAC decorative PVD films are routinely used as a replacement for electroplated chrome. They can be applied directly over almost

any substrate material and can be deposited in a wide variety of colors. The process parameters to deposit each color are stored

in software recipes with different process steps. Once the coating process has started, all of the relevant process parameters are

continuously monitored and controlled by the on-board computer software.

* High productivity and flexibility

* Consistently brilliant end product quality

* Full automation capability

* Excellent coating flexibility

* Long lifetime and fast target exchange

* Flexible system configuration

* High speed coating and best PVD homogeneity

HCVAC decorative PVD films are routinely used as a replacement for electroplated chrome. They can be applied directly over almost

any substrate material and can be deposited in a wide variety of colors. The process parameters to deposit each color are stored

in software recipes with different process steps. Once the coating process has started, all of the relevant process parameters are

continuously monitored and controlled by the on-board computer software.

Application

This machine is extensively used in the fields of ultra-hard coating for the tools and mould, decorative coating for watch, jewelries, stainless steel tableware, golf head, hotel product, sanitary ware, luminaires, optical frame, hardware, etc .

Hot Searches