1.All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

2.304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

3. 304/316 stainless steel washing pump

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥99.7%

-

Voltage:

-

220v/380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Big boss

-

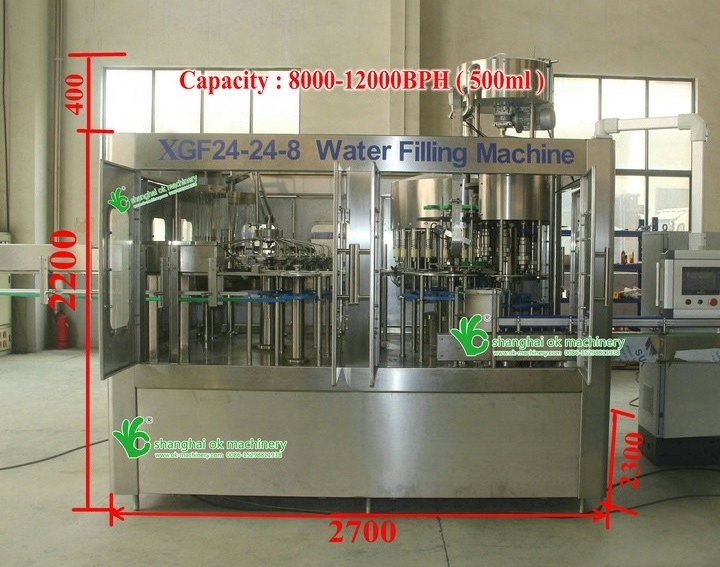

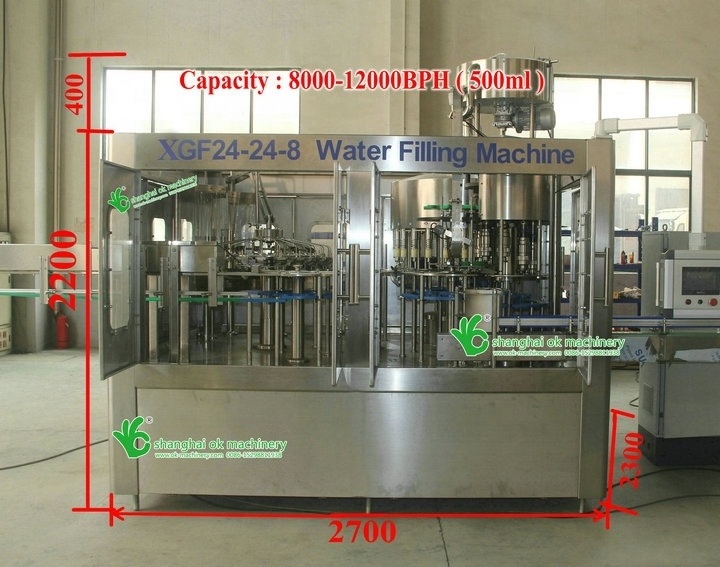

Dimension(L*W*H):

-

2700*2300*2200mm

-

Weight:

-

3200 KG

-

Product name:

-

water filling machine

-

Name:

-

Water Washing Filling

-

Usage:

-

Beverage Packaging

-

Function:

-

Bottle Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Keywords:

-

Fillng Machine

-

Capacity:

-

2000-36000bph

-

Material:

-

Stainless Steel 304/316

-

Control:

-

PLC+ Touch Screen

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

≥99.7%

-

Voltage:

-

220v/380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Big boss

-

Dimension(L*W*H):

-

2700*2300*2200mm

-

Weight:

-

3200 KG

-

Product name:

-

water filling machine

-

Name:

-

Water Washing Filling

-

Usage:

-

Beverage Packaging

-

Function:

-

Bottle Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Keywords:

-

Fillng Machine

-

Capacity:

-

2000-36000bph

-

Material:

-

Stainless Steel 304/316

-

Control:

-

PLC+ Touch Screen

-

After Warranty Service:

-

Video technical support

Product Description

The series injection type gravity type dual-use filling machine is a high-tech product researched and developed by our company. It is suitable for products of various viscosities such as water injection, semi-fluid, ointment and shampoo etc. It is widely applied for filling of products in such industries as food, cosmetics, medicine, grease, daily chemical industry,detergent,pesticide and chemical industry etc. By adopting straight line filling model, it can be used to fill solution of different types without the need of adding any spare parts.

Product Paramenters

Water filling video

The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

2.3 in 1 bottle water procution line video . this video will show you washing bottle inside and outside , filling water into bottle put cap on bottle and capping it . after all will inlet with Flat conveyor belt . Automatic water filling production line

|

Model

|

XGF16-16-5

|

XGF24-24-8

|

XGF32-32-8

|

XGF40-40-10

|

|

Capacity

|

8000BPH

|

12000BPH

|

15000BPH

|

20000BPH

|

|

Machine power

|

3.5kw

|

5.5kw

|

7.5kw

|

11kw

|

|

Machine weight

|

3800kg

|

4200kg

|

5000kg

|

9000kg

|

|

Mchine size

|

2700-2000*2200

|

2700-2300*2200

|

3000*2300*2200

|

3800*2850*2200

|

Washing heads.

Filling heads.

1.304/316 Stainless steel high precision filling nozzle

2.Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

2.Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

Capping heads.

1.Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2. All 304/316 stainless steel construction

3. No bottle no capping

4.Automatic stop when lack of bottle

3. No bottle no capping

4.Automatic stop when lack of bottle

Product details

Specification

Hot Selling Products

1.Flat Conveyor

-Energy saving. High efficient. Adapt to customer factory layout -

Special lubrication system, keep products clean, health,safety - Extended service life

- Electric eyes design keep whole line running safety and quickly

2.Shrinking label machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is,

four-wheel driving, self-centering and balanced pressure of four wheels.

four-wheel driving, self-centering and balanced pressure of four wheels.

3.Water treatment system

Stainless steel high pressure film shellAll kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system Online type pressure auto self-protection device Online type electricity indicator System safe protecting and alarm system System frame

4.Bottle blowing machine

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used

to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

OK Machine Advantages

Hot Searches