- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RETEKOOL

-

Liquid Flow Rate:

-

none

-

Maximum Working Pressure:

-

none

-

Weight:

-

5 KG

-

Dimension(L*W*H):

-

customize

-

Working Temperature Range:

-

customize

-

Product Name:

-

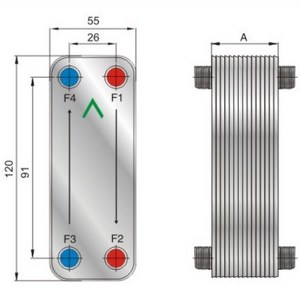

Plate Heat Exchanger

-

Application:

-

Heat Transfer

-

Type:

-

Plate Fin Heat Exchanger Core

-

Material:

-

SS304/SS316L

-

Tube material:

-

SS304/SS316/SS316L/Carbon Steel/Cast Iron

-

Keyword:

-

High Efficiency Clean Stream Heat Exchanger

Quick Details

-

Structure:

-

Plate Heat Exchanger

-

Voltage:

-

220

-

Place of Origin:

-

China

-

Brand Name:

-

RETEKOOL

-

Liquid Flow Rate:

-

none

-

Maximum Working Pressure:

-

none

-

Weight:

-

5 KG

-

Dimension(L*W*H):

-

customize

-

Working Temperature Range:

-

customize

-

Product Name:

-

Plate Heat Exchanger

-

Application:

-

Heat Transfer

-

Type:

-

Plate Fin Heat Exchanger Core

-

Material:

-

SS304/SS316L

-

Tube material:

-

SS304/SS316/SS316L/Carbon Steel/Cast Iron

-

Keyword:

-

High Efficiency Clean Stream Heat Exchanger

Application

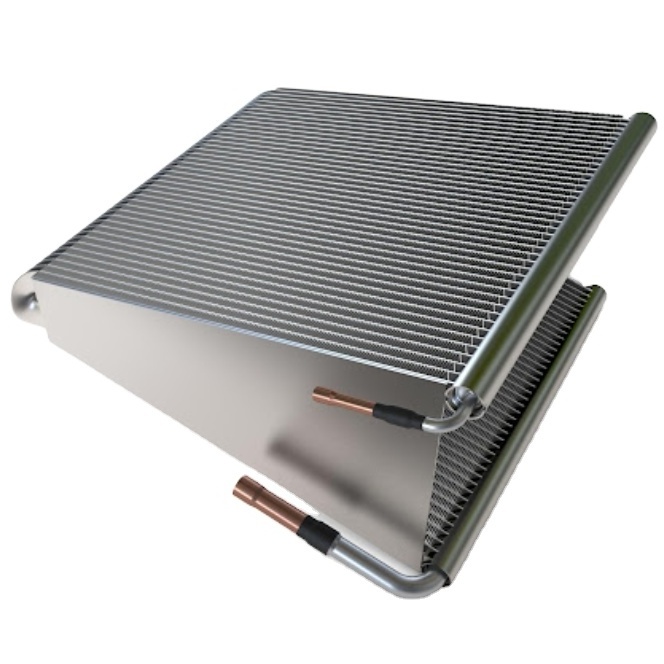

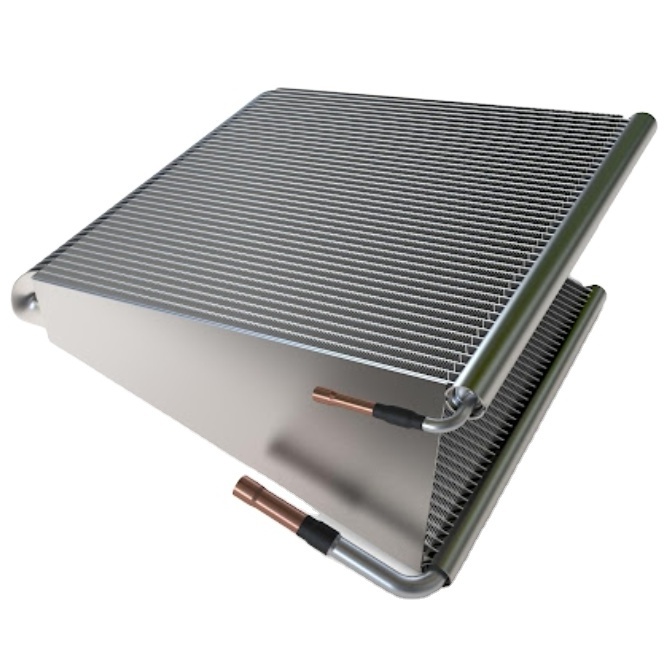

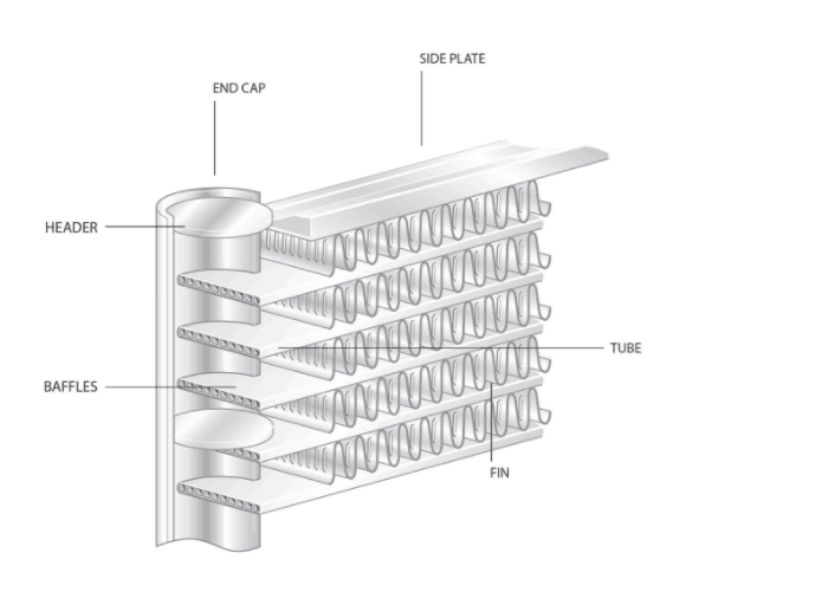

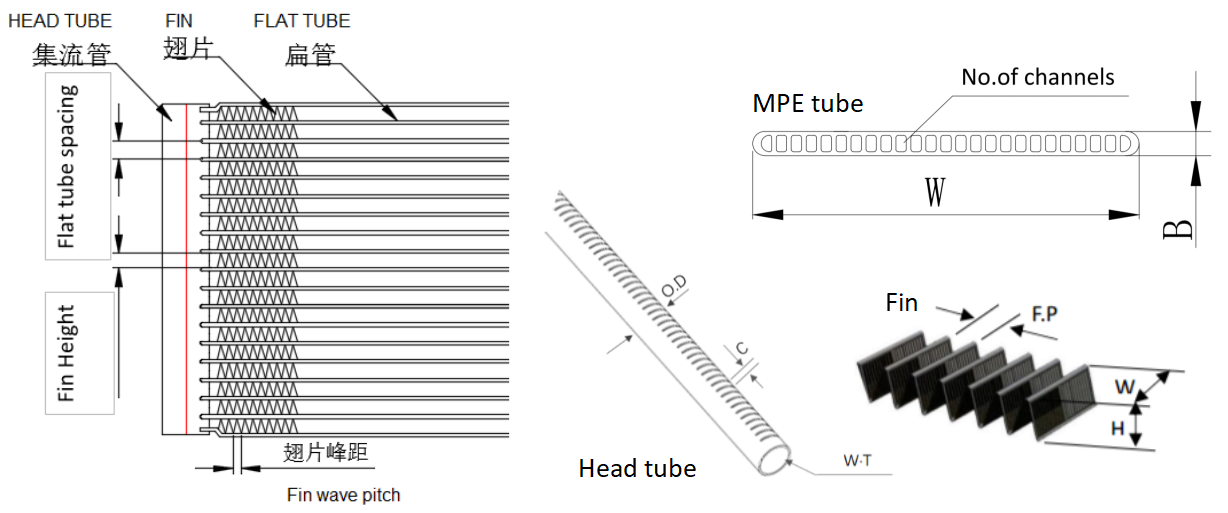

Microchannel heat exchanger (MCHE) is a highly compact heat exchanger, whole body aluminum structure, the diameter of a single control refrigerant circulating about 1MM. Compared with conventional finned tube heat exchanger, MCHE using micro-sized heat transfer technology, smaller, lighter, heat rate increased by 50%, 50% less refrigerant charge fluence, fan power consumption is reduced accordingly.

Application:

Application:

Micro-channel heat exchanger, the diameter of the flat tube channel is 0.8-1.2mm, there are dozens of mini-size flow channels in a single flat tube, the fin use rolling window structure and the heat exchanger is integrally brazed. Compared with traditional Tube & Fin heat exchanger, micro channel heat exchanger has high performance, small size, less weight, less refrigerant charge, has gradually become a new generation of heat exchange solutions since the 1980s. Today, micro channel heat exchanger has widely used in automobiles, air conditions, household appliances, food cold chain, industrial cooling, electronic cooling, data center cooling, dehumidifiers and so on.

Equivalent diameter of Microchannel Heat Exchanger is between 10 and 1000 microns. Microchannel Heat Exchanger is composed of header, flat tubes and fin, which is used in the refrigeration industry and its main material is aluminum.

It is new type of compact heat exchanger with high efficient that is the substituted choice of parallel-fin heat exchanger by its high dependability, compact structure, light weight and economical cost.

Residential and Commercial HAVCR

Cold chain delivery for food, medcine, etc.

Refrigeration and freezing equipment.

Equivalent diameter of Microchannel Heat Exchanger is between 10 and 1000 microns. Microchannel Heat Exchanger is composed of header, flat tubes and fin, which is used in the refrigeration industry and its main material is aluminum.

It is new type of compact heat exchanger with high efficient that is the substituted choice of parallel-fin heat exchanger by its high dependability, compact structure, light weight and economical cost.

Residential and Commercial HAVCR

Cold chain delivery for food, medcine, etc.

Refrigeration and freezing equipment.

|

* High efficiency

|

1. averagely 30% higher heat exchanger performance.

|

|

|

2. averagely 20% lower air side pressure drop.

|

|

|

3. AC unit COP highly increased.

|

|

* High reliability

|

1. sustainable high efficiency as metalic bonding.

|

|

|

2. more adapt to high pressure system as micro channel design.

|

Details Images

Products Description

Specification and function of the heat exchanger

https://jretek.en.alibaba.com/product/1600733777589-213113636/Oil_Cooler_refrigeration_microchannel_condenser.html

Tube and fin brazed tightly, no any loose

No leakage at any brazed or welding point

Surface cleaning and bright, fins are all regular, without obvious deformation or damage

Surface can be black E-coated, coating thickness Min18um, the layer is equally, no blank or peel off.

Heat exchanger can suit for below refrigerant and it’s pressure standard:

* fluid(Glycol & Water mixed) cooler coil: working pressure0.5~1.0MPa, burst pressure3.0~0MPa

* if R22,R134a,R600a, R407C,R410a, working pressure3.0~5MPa, burst pressure Min13.5MPa

https://jretek.en.alibaba.com/product/1600733777589-213113636/Oil_Cooler_refrigeration_microchannel_condenser.html

Tube and fin brazed tightly, no any loose

No leakage at any brazed or welding point

Surface cleaning and bright, fins are all regular, without obvious deformation or damage

Surface can be black E-coated, coating thickness Min18um, the layer is equally, no blank or peel off.

Heat exchanger can suit for below refrigerant and it’s pressure standard:

* fluid(Glycol & Water mixed) cooler coil: working pressure0.5~1.0MPa, burst pressure3.0~0MPa

* if R22,R134a,R600a, R407C,R410a, working pressure3.0~5MPa, burst pressure Min13.5MPa

Hot Searches