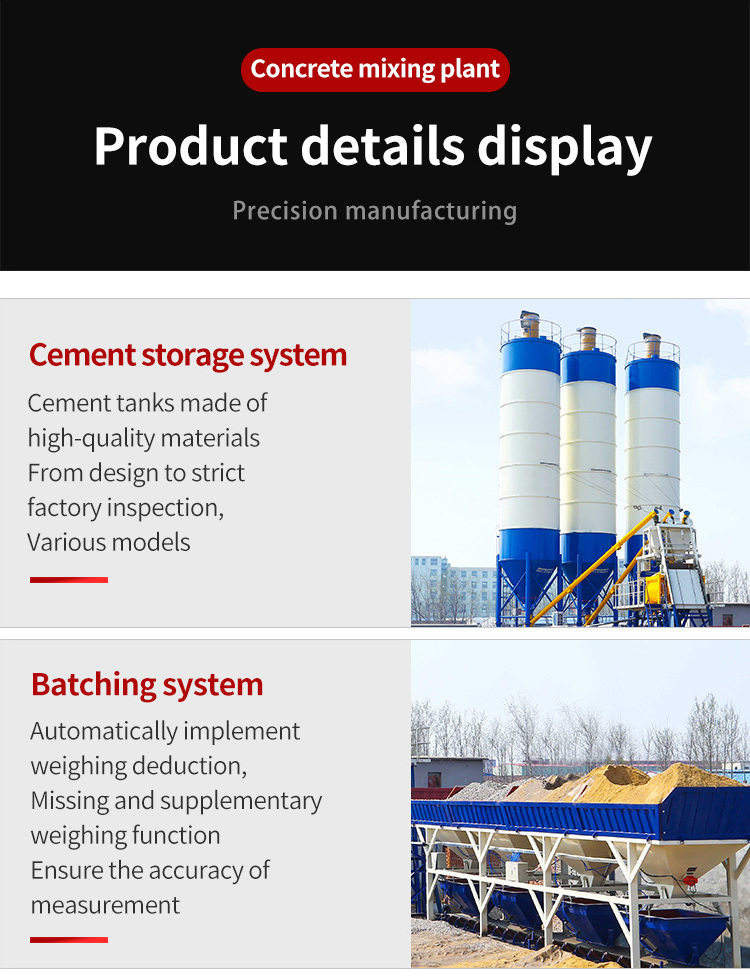

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4.1*2.1*2.4m

-

Weight:

-

2000 kg

-

Product name:

-

Concrete Mixing Plant

-

Keyword:

-

Automatic Concrete Batching Plant

-

Capacity:

-

40m3/h

-

After-sales Service Provided:

-

Field Installation

-

Type:

-

Stationary Automatic Concrete Plant

-

Advantage:

-

High Production Efficiency

-

Batching Machine:

-

PLD800-3200

-

Application:

-

Construction Industry

-

Color:

-

Optional

-

WHTAA..SPP:

-

86-15515682190

Quick Details

-

Machine Type:

-

Production line

-

Place of Origin:

-

China

-

Power:

-

22

-

Dimension(L*W*H):

-

4.1*2.1*2.4m

-

Weight:

-

2000 kg

-

Product name:

-

Concrete Mixing Plant

-

Keyword:

-

Automatic Concrete Batching Plant

-

Capacity:

-

40m3/h

-

After-sales Service Provided:

-

Field Installation

-

Type:

-

Stationary Automatic Concrete Plant

-

Advantage:

-

High Production Efficiency

-

Batching Machine:

-

PLD800-3200

-

Application:

-

Construction Industry

-

Color:

-

Optional

-

WHTAA..SPP:

-

86-15515682190

Product Description

Mobile Concrete Batching Plant

.

Functions of mobile concrete batching plant

finished in the pulling chassis, combining aggregate, electronic weighing, mixing and lifting together. It can be

stopped to run or be pulled away easily, which is convenient to move and easy to install. It is can applied

to various construction sites like road surface, bridges, dams and airport, and also like architectural

.

Why don't

contact me?

1. Provide most suitable machine model

2. Provide the most suitable construction plan

3. Get the latest discounts on purchases!

Note: Scan WhatsApp QR code

1. Open WhatsApp and tap Settings.

2. Tap the QR code icon displayed next to your name.

3. Click Scan > OK.

4. Hold the device and scan it at the top of the QR code.

5. Click Add Contact.

6. Open wealth~

Product Paramenters

|

Main

|

Plant Model

|

YGS25

|

YGS35

|

YGS60

|

YGS75

|

||||

|

|

Theo. Mixing Capacity

|

25m3/h

|

35m3/h

|

60m3/h

|

75m3/h

|

||||

|

|

Concrete Discharge Height

|

3.8m

|

3.8m

|

4.1m

|

4.1m

|

||||

|

|

Raw Material Feeding

|

Belt Conveyor

|

Belt Conveyor

|

Belt Conveyor

|

Belt Conveyor

|

||||

|

|

Max. Aggregates Size

|

60mm

|

80mm

|

80mm

|

80mm

|

||||

|

|

Mixing Time per Batch

|

60-72s

|

60-72s

|

60-72s

|

60-72s

|

||||

|

Batching Machine

|

Model

|

PLD800

|

PLD1200

|

PLD1600

|

PLD2400

|

||||

|

|

Aggregates Feed Height

|

3.5m

|

3.1m

|

4.5m

|

4.8m

|

||||

|

Twin Shaft Concrete Mixer

|

Model

|

JS500

|

JS750

|

JS1000

|

JS1500

|

||||

|

|

Raw Material Feeding

|

Belt Conveyor

|

Belt Conveyor

|

Belt Conveyor

|

Belt Conveyor

|

||||

|

|

Mixing Motor

|

18.5kw*1

|

30kw*1

|

22kw*2

|

30kw*2

|

||||

|

|

Feeding Motor

|

7.5kw

|

7.5kw

|

11kw

|

11kw

|

||||

|

Weighing

|

Cement Weighing

|

Yes

|

Yes

|

Yes

|

Yes

|

||||

|

|

Water Weighing

|

Yes

|

Yes

|

Yes

|

Yes

|

||||

|

|

Additive Weighing

|

Yes

|

Yes

|

Yes

|

Yes

|

||||

|

Screw Conveyor

|

Model

|

219-6

|

219-6

|

219-8

|

219-8

|

||||

|

|

Conveying Distance

|

6m

|

6m

|

8m

|

8m

|

||||

|

|

Motor Power

|

7.5kw

|

7.5kw

|

11kw

|

11kw

|

||||

|

Cement Silo

|

Type

|

Vertical Bolted

|

Vertical Bolted

|

Vertical Bolted

|

Vertical Bolted

|

||||

|

|

Storage Capacity

|

50/100t

|

50/100t

|

100t*2

|

100t*2

|

||||

|

Control System

|

Model

|

Both computer type full-auto control and button type semi-auto control are available, depending on the customers' needs.

|

|

|

|

||||

|

|

Control Room

|

Yes

|

Yes

|

Yes

|

Yes

|

||||

|

Note

|

bigger mobile concrete plant such as 120m3/h and 150m3/h are available.

|

|

|

|

|

||||

Product Display

Product Real Shot

Product Usage

Our service

1.Whole process guidance

With more than 15 years of service experience,

we will spare no effort to provide support in selecting equipment, customizing production lines, improving supply chain, and post-optimization etc.

2.Provide a full set of construction method and equipment training

Provide design and construction solutions in terms of cost budget / progress improvement / quality control / safety management.

3.After-sales service system

Fully track the service system, focus on customer needs, first-class speed, skills, attitude, and provide support for customers' construction.

phone: 00 86 155 1568 2190

4.Support customization

Relying on our powerful flexible production line, we can give you the right to fully choose the mold, drive method, accessories upgrade, shell material, appearance color and Logo etc.

5.Extensive spare parts service

The spare parts warehouse of more than 50,000 square meters can meet the timely replacement and supplement of any wearing parts.

6.Support sea, land and air transportation

We can ship products to every corner of the world. If you need, we also support a series of tedious tasks such as customs clearance and tail end delivery.

Product Packaging

Packaging Details

1. Out package: Standard marine export plwywood cases;

2. Innner package:Stretch film and plastic film for humidity;

3. Customized according to your requirement.

Delivery Time

Within one week

Shipping

Port: Tianjin, Qingdao, Shanghai or other ports according to your requirements.

Sea freight: FOB/CIF/DDU quotation are all available.

Transport method: By logistics; by automobile; by train; by shipping; by air etc.

2. Innner package:Stretch film and plastic film for humidity;

3. Customized according to your requirement.

Delivery Time

Within one week

Shipping

Port: Tianjin, Qingdao, Shanghai or other ports according to your requirements.

Sea freight: FOB/CIF/DDU quotation are all available.

Transport method: By logistics; by automobile; by train; by shipping; by air etc.

FAQ & Contact

Q: I just started to enter these industries? Don't know what to do?

A: We will assist you to choose a cost-effective machine; we will provide assistance in purchasing raw materials, equipment debugging, and later technical guidance.

Q: How can I ship these machines to my company after purchase?

A: We have a stable and cooperative freight forwarder and have rich experience. We can be responsible for the whole process of transportation/customs declaration/customs clearance/transportation, and transport the goods to your company.

Q: Can you tell us about your service and support throughout the process?

A: I think selling a machine is just the start of our partnership

1.We will provide technical solutions, product selection guidance, and related supporting equipment support before sales

(For example, to help you identify hot-selling products in the market to determine machine selection)

2.Provide regular feedback on manufacturing progress in production Pictures or videos

3.Provide machine testing after sale; free accessories; stable packaging; product shipping to your factory , customs clearance and shipping services we can also cover;

4.During production: continuous debugging of the machine; raw material supply etc.

Hot Searches