- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2610*1010*1610mm

-

Weight:

-

350 KG

-

Machine frame:

-

SUS304 Stainless steel

-

Control parts:

-

Touch screen PLC

-

Main motor:

-

ABB

-

Inverter:

-

Mitsubishi

-

Capping type:

-

Pressing

-

Price:

-

Shanghai factory direct sales

-

Appearance:

-

Professional

-

Advantage:

-

Can be customized according to your cap/bottle

-

Packing:

-

Long distance exported wooden case

-

Product name:

-

Bottle capping machine

Quick Details

-

Voltage:

-

380V 50HZ

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

CHENGXIANG

-

Dimension(L*W*H):

-

2610*1010*1610mm

-

Weight:

-

350 KG

-

Machine frame:

-

SUS304 Stainless steel

-

Control parts:

-

Touch screen PLC

-

Main motor:

-

ABB

-

Inverter:

-

Mitsubishi

-

Capping type:

-

Pressing

-

Price:

-

Shanghai factory direct sales

-

Appearance:

-

Professional

-

Advantage:

-

Can be customized according to your cap/bottle

-

Packing:

-

Long distance exported wooden case

-

Product name:

-

Bottle capping machine

Model No:CX-DSG

Machine name:Automatic capping machine

Can be customized for pump cap,trigger cap,flip cap,screw cap,jar...

Finished products with high accuracy, loved by customer

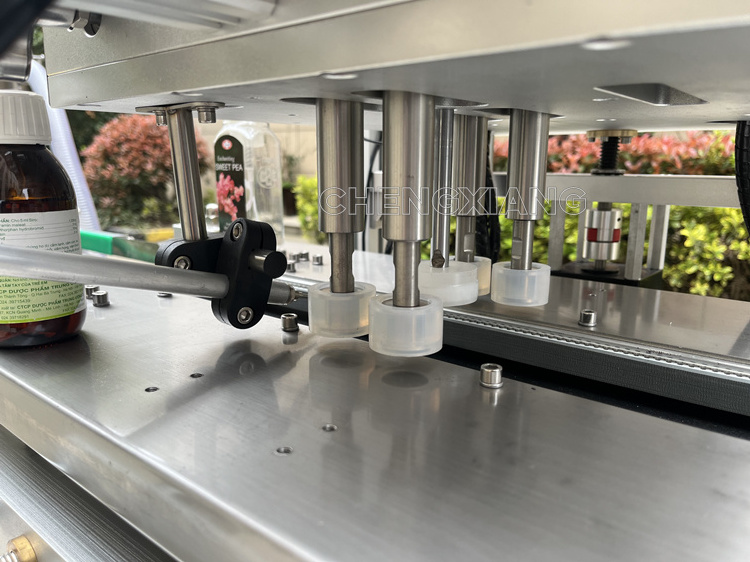

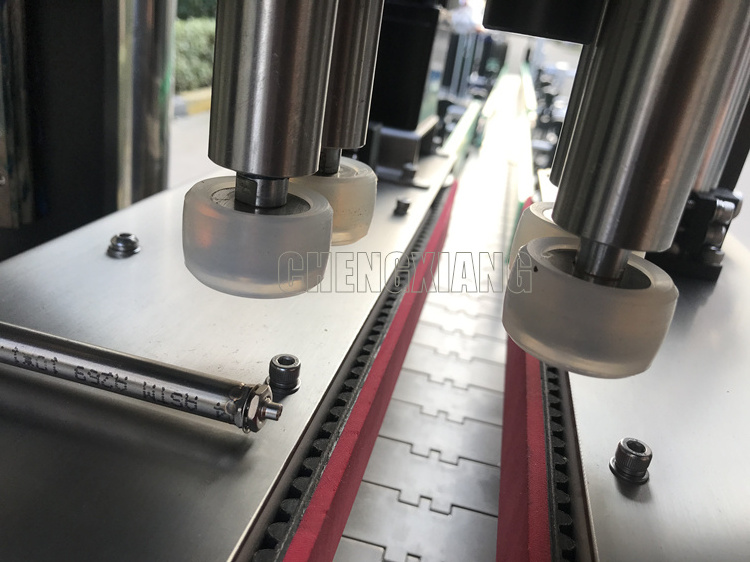

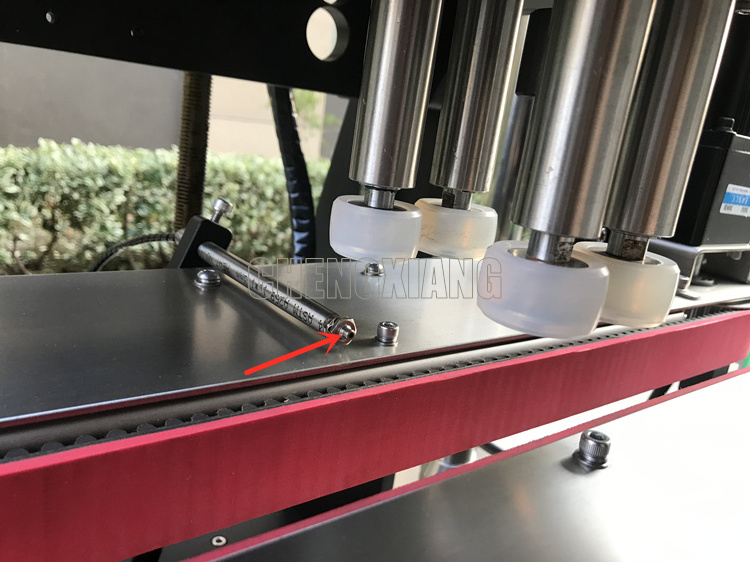

Bottle clamping belt, more efficient and stable

Sensor checking& high-quality screw cap silicone wheels

to protect bottle caps from scratches

Touch screen PLC control

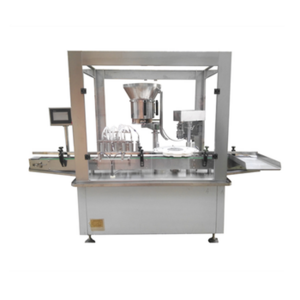

Finished automatic capping machine

Can be connected with your exsting production line easily

We pack all quick wear parts,manual,operation & installation video,

tool and whole machine in wooden case, more easy for set up

Finished samples,can be customized for different bottle/cap size

Machine Introduction:

Automatic servo torque capping machine is based on the international advanced model to improve the design, the application of servo torque control capping speed, no damage to the cap, high qualification rate, simple and convenient operation. It can be applied to different bottle shape screw caps in food, pharmaceutical, daily chemical, pesticide, cosmetics and other industries. The machine has a high degree of automation, good stability, easy adjustment, (if equipped with a lid machine, it can be automatically covered) can be selected according to actual needs.

Technical data :

|

Adapt to bottle height |

4 0mm-2 0 0mm (can be customized) |

|

Adapt to bottle diameter |

20mm- 7 0mm (can be customized) |

|

Capping speed |

20-80 b/m (depending on the filling volume, material and packaging material) |

|

A ir pressure (mpa) |

0.5-0.7 |

|

Speed control |

frequency conversion speed regulation |

|

Equipment size: |

1900X 9 00X1600 (mm) |

|

Power supply |

220V/110V 50/60Hz |

|

Power |

2.0 kw |

Main configuration:

|

Machine material |

The countertop and surrounding panels are imported 304/2B high-quality stainless steel |

|

PLC |

Siemens (Germany) |

|

Touch screen |

Siemens (Germany) |

|

Servo motor |

XINJE (China) |

|

Servo-driv e |

XINJE (China) |

|

Cylinder |

AIRTAC ( Taiwan China) |

|

Photoelectric sensor |

SICK(Germany) |

|

Pneumatic configuration |

AIRTAC ( Taiwan China) |

|

Low voltage Appliance |

Schneider (France) |

|

Pneumatic configuration |

AIRTAC ( Taiwan China) |

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality :

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side

(round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging.

Q1.Are you the factory?

A1:Yes,we are 18 YEARS manufacturer of filling-capping-labeling-bottle washing machine, our factory is in Shanghai.

Q2.What's the payment terms and trade terms for new customers?

A2: Payment terms:T/T,L/C,D/P,O/A, Western Union etc.

Trade terms:EXW,FOB,CIF,C&F...

Q3:What's the Minimum Order Quantity and warranty?

A3:MOQ:1 set

Warranty:12 months,some customized products will be 24 months.

Q4:Your standard please?

A4:CE/ISO/TUV/GMP,more details as below: