- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

new

-

Marketing Type:

-

New Product 2021

-

Capacity:

-

100-300 KG/H

-

Type:

-

Automatic

-

Product:

-

Toile and laundry saop machine

-

VOLTAGE:

-

220V/380V or customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Double Birds

-

Weight (KG):

-

2500

-

Machine Type:

-

new

-

Marketing Type:

-

New Product 2021

-

Capacity:

-

100-300 KG/H

-

Type:

-

Automatic

-

Product:

-

Toile and laundry saop machine

-

VOLTAGE:

-

220V/380V or customized

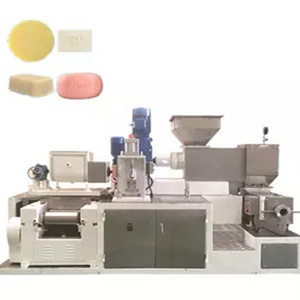

bar soap making machine small for sale

In your inquiry, please let me know

1, Toilet soap or laundry soap, which soap will you make?

2, Capacities are 150-300, 300-600, 600-1000kg/h, 2000-3000kg/h . wh at capacity do you need?

3.what is the material? oil or soap noodles?

March 2019 , customer's soap making

Main process

1. Mix all materials by mixing agitator, grind soap noodles by three-roller mill, make soap materials into soap bar by vacuum plodder, and cut soaps by stamping machine.

2. Distribution boxes are used to control all the motors of machines, and conveyors are used to transport soap materials.

3. Water pump is used to make the water to cool down the vacuum plodder, and vacuum pump is used to vacuumize the soap materials.

4. The parts of mixing agitator and vacuum plodder that touch the soap materials can be made of stainless steel 304.

Capacities for choosing

3 roller milling machine

Specification

1. size :1350*1670*1050mm

2. power :15kw ,

3. frequency :50HZ

4. voltage :380v

5. functon :rubbing soap material

Double layer vacuum plodder machine

1. size: 3750*900*2100mm

2. power :35.5kw ,

3. frequency :50HZ

4. voltage :380v

5. functon : vacuum ploddering

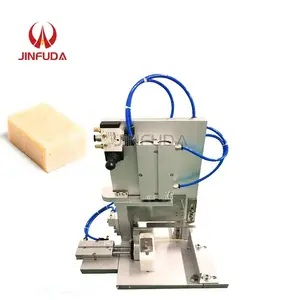

Soap stamping machine

Capacity: 150-300kg/h

Power : 5kw , 7. 5 kw adjustable motor

Dimension :4000*1000*2450mm

Weight : 2800kg

Soap cutting machine

1.size :800*300*1000mm

2.power :6kw

3.frequency :50HZ

4.voltage :380v

5.functon :cutting and printing

Laundry Soap Making

1.

This laundry soap production line take soap noodles(soap bar) as raw materials.

2.

The production starts with mixing soap bar,perfume pigment and,etc.

Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets are made.

3.

The soap thin sheet then converted into desired long strip soap by the plodder machine.

4.

Then the long strip soap are cut into the soap bars required size by cutting machine(there are two kinds of cutting machine.One is mechanical.The other is automatic).

5.

Finally, the soap bars gets packed by packing machine if needed.

6.

Soap bars can be made 60g,120g,200g,260g,and so on

Soaps made by clients

2nd March 2019 , customer's visit and checked his soap line

26th July 2019 , customer's visit and ordered 300-500kg/h soap line via our local bank