- Product Details

- {{item.text}}

Quick Details

-

Name:

-

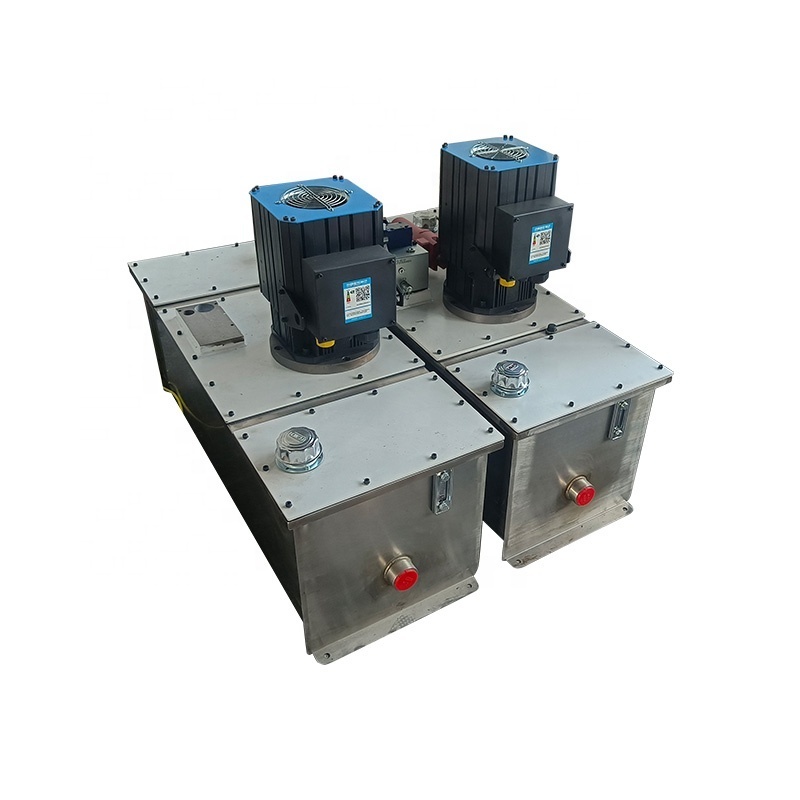

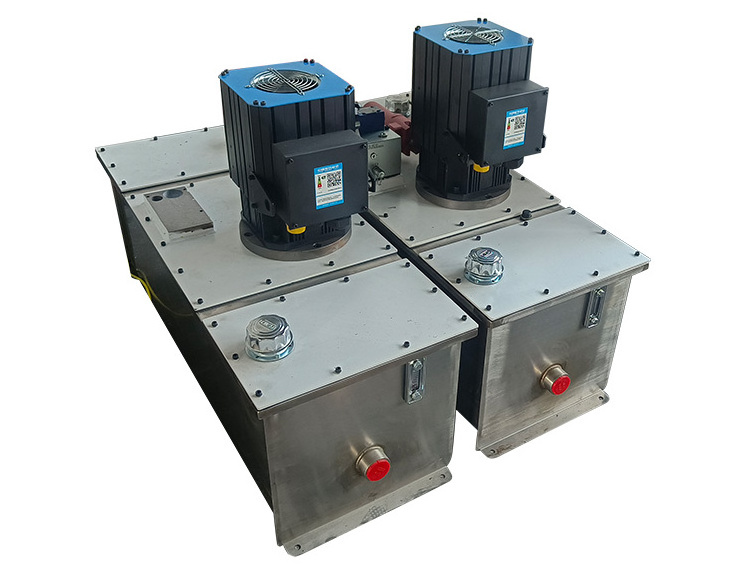

stainless steel independent oil tank

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Package:

-

Wooden Box

-

Application:

-

cnc press brake

-

Usage:

-

Spare Parts

-

Keyword:

-

independent oil tank

-

Material:

-

Stainless Steel

-

Structure:

-

dependent

Quick Details

-

Weight (KG):

-

300

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

RONGWIN

-

Name:

-

stainless steel independent oil tank

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Package:

-

Wooden Box

-

Application:

-

cnc press brake

-

Usage:

-

Spare Parts

-

Keyword:

-

independent oil tank

-

Material:

-

Stainless Steel

-

Structure:

-

dependent

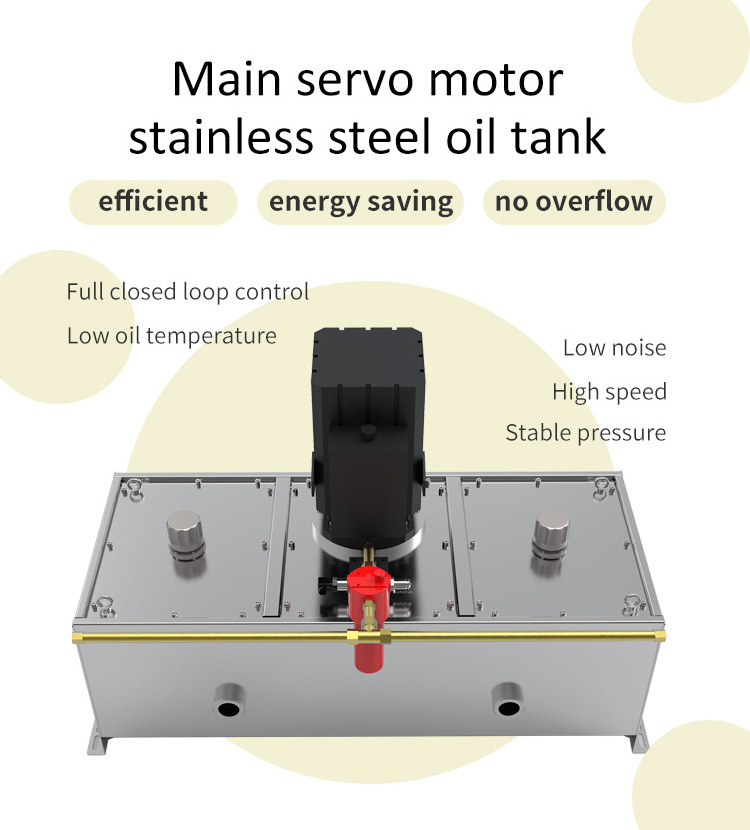

Product Description

Hot Sale Fuel Tank Motorcycle Fuel System Motorcycle Oil Tank Moped Tanks For DT125

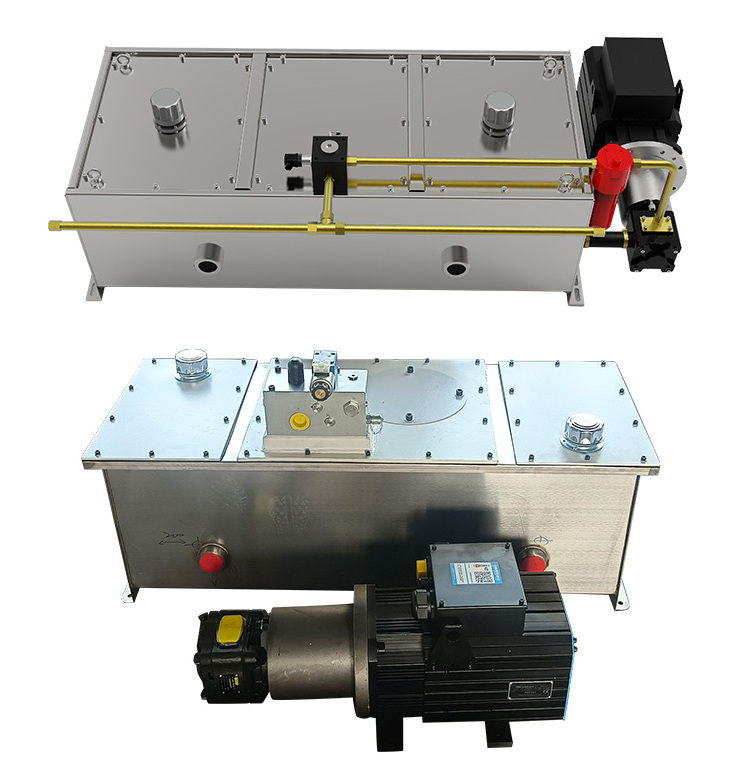

1. The electro-hydraulic servo system adopts on-demand oil supply mode to reduce overflow and save energy by more than 30%.

2. Heat balance temperature is low, fuel tank capacity is reduced,service life of hydraulic system and components is prolonged.

3. Long interval of oil change,reduce energy waste and reduce user cost.

4. When bending the workpiece of different specification,the speed can be adjusted.

5. High precision,energy saving,environmental protection and efficiency.

Features

– Minimize overflow losses.

– Stepless speed regulation is possible. The adjustment range is 0 to max.

– Fully adapt to the use characteristics of the bending machine, and minimize useless power consumption through real-time intelligent control of the servo motor speed.

– Precise oil dosing on demand, optimized by dynamic servo motor speed.

– No idle power: Servo motors can be turned off when flow or pressure is not required.

– Fast down and return speed up to 200mm/s, working speed up to 20mm/s

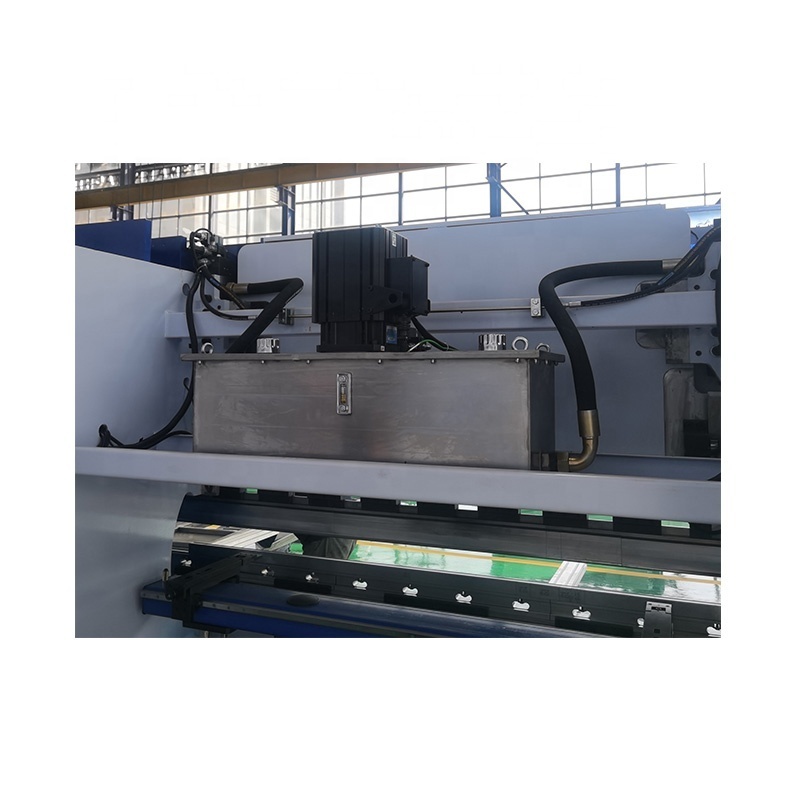

– Compact design for easier installation.

– The machining difficulty of the oil cylinder is reduced, and the cost is reduced.

– The stainless steel oil tank is used, and the oil pump is easy to disassemble.

- Province. 40% power saving compared with traditional transmission

- High. Work efficiency can be increased by 30% (reduced cycle time)

- Accurate. The positioning accuracy is more accurate, up to 5um

- Quiet. Noise reduction, the machine tool works more quietly

- Few. The use of hydraulic oil is very small, only 20% of the traditional

- Easy. Machine tool manufacturing is easier, maintenance is easier, and debugging is easier

Detailed Images

Main Motor

The electro-hydraulic servo system adopts on-demand oil supply mode to reduce overflow and save energy by more than 30%

Independent oil tank

Over 85% of the bending machine are related to the cleanliness of the hydraulic oil passage. This independent tank with special processing technology, which can reduce the faults related to hydraulic oil to the greatest extent, ensure the stable operation of the machine tool and reduce the failure rate of the equipment.

Related Products

Packing&Shipping

|

Quantity(Sets)

|

1-5

|

>5

|

|

Est. Time(days)

|

30

|

Negotiable

|

Company Introduction

Nanjing Rongwin Machinery Technology Co.,Ltd.

specializing in various kinds of metal working machine,such as press brake ,shearing machine , laser cutting machine ,power press ,V grooving machine, hydraulic press , ironworker ,notching machine ,rolling machine, shearing machine blade ,press brake tooling , punching die and spare parts etc . We can give customer all the aspect solutions for the metal industry fabrication machinery. Our experienced engineer can give customer good suggestions according to customer’s metal products photos or design drawings, we can guide customers for choosing their metal processing equipment so that customer can get the most cost-effective solution by our guide. Meanwhile we also can do OEM & ODM service.

Our factory located in a metal fabrication machine and blades industry area . we can make fiber laser cutting machine , press brake brake ,shearing machine ,V grooving Machine ,press brake and shearing machine ,tooling and blades with more than 30 years manufacturing experience . all of our machines and tools meet CE and ISO Certificate . we have more than 150 staffs , our factory covers an area of 85000 square meters, 5 R&D Department . We also have more than auxiliary supporting factories . So we can supply you one stop metal fabrication solution chain .we have sold our products to more than 70 countries,like USA,CANADA,European country,Middle East country, Asia countries, South-American countries,Russia,C.I,S countries.and more than 10 directly agents oversea.

Why Choose Us

FAQ

Q: Are you factory or manufacture?

A:

YES.We are group factories agent exporting company.We have more than 10 directly factories

Q: What's your delivery time?

A: 30 days for machine and 20 days for tools and blades,and spare parts after confirmed order with payment

Q: What's kinds of shipping you choose after order?

A: Usually we choose FCL,Or LCL by sea.

We also can supply door to door shipping service by air or intermational express.

Q: Which kinds of Payment and MOQ?

A: We can accept TT,LC or Trade assurance.MOQ:1 set for machine order

Q: What's your packing?

A: Fumigation-free plywood case for small machine in LCL Shipment by sea,and blades and tools and spar parts.

If FCL shipping by sea we just professional fixed in container without cover.

Q: What's your Warranty Time?

A: THREE Year Warranty for machine,Lifelong maintenance.

During warranty time which the broken parts and spares caused by quality can be Offered free.

Q: Can you support overseas commissioning or traning service?

A: YES.We CAN.But the buyer need to afford this cost,tickets and foods,hotel etc.

Q: What's your delivery time?

A: 30 days for machine and 20 days for tools and blades,and spare parts after confirmed order with payment

Q: What's kinds of shipping you choose after order?

A: Usually we choose FCL,Or LCL by sea.

We also can supply door to door shipping service by air or intermational express.

Q: Which kinds of Payment and MOQ?

A: We can accept TT,LC or Trade assurance.MOQ:1 set for machine order

Q: What's your packing?

A: Fumigation-free plywood case for small machine in LCL Shipment by sea,and blades and tools and spar parts.

If FCL shipping by sea we just professional fixed in container without cover.

Q: What's your Warranty Time?

A: THREE Year Warranty for machine,Lifelong maintenance.

During warranty time which the broken parts and spares caused by quality can be Offered free.

Q: Can you support overseas commissioning or traning service?

A: YES.We CAN.But the buyer need to afford this cost,tickets and foods,hotel etc.

Hot Searches