- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

360

-

Dimension(L*W*H):

-

2220*1650*2350mm

-

Weight (T):

-

3 T

-

Spindle Motor Power(kW):

-

5.5

-

Max. Table Load(kg):

-

400 kg

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SOSEN

-

Voltage:

-

as customer's requirement

-

Marketing Type:

-

Hot Product

-

Table size:

-

1250*360mm

-

Table loading capacity:

-

400kgs

-

CNC controller:

-

KND, FANUC,SIEMENS, GSK

-

X-axis travel:

-

900mm

-

Y-axis travel:

-

360mm

-

Z-Axis Travel:

-

480mm

-

Spindle nose taper:

-

BT40

-

Max.spindle speed:

-

8000rpm

-

Machine Type:

-

Vertical CNC Machining Center

-

Color:

-

Customer's Requirement

Quick Details

-

Table Size (mm):

-

1250x360

-

Number of Axes:

-

3

-

Table Travel (X) (mm):

-

900

-

Table Travel (Y) (mm):

-

360

-

Dimension(L*W*H):

-

2220*1650*2350mm

-

Weight (T):

-

3 T

-

Spindle Motor Power(kW):

-

5.5

-

Max. Table Load(kg):

-

400 kg

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SOSEN

-

Voltage:

-

as customer's requirement

-

Marketing Type:

-

Hot Product

-

Table size:

-

1250*360mm

-

Table loading capacity:

-

400kgs

-

CNC controller:

-

KND, FANUC,SIEMENS, GSK

-

X-axis travel:

-

900mm

-

Y-axis travel:

-

360mm

-

Z-Axis Travel:

-

480mm

-

Spindle nose taper:

-

BT40

-

Max.spindle speed:

-

8000rpm

-

Machine Type:

-

Vertical CNC Machining Center

-

Color:

-

Customer's Requirement

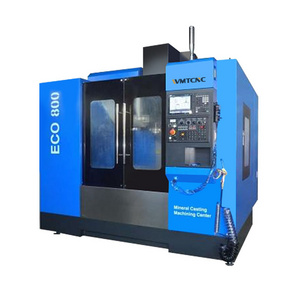

CNC VMC milling machine center with automatic tool changer

Features:

CNC VMC milling machine center with automatic tool changer is a CNC bed milling machine with strong bearing capacity. The three-way guide rails are hardened hard rails. The guide rails are wide and span, and the structure and external dimensions are compact and reasonable. The spindle is driven by a synchronous belt. It can be used for milling, drilling, reaming and reaming. It can process complex and high-precision parts such as discs, plates, shells and molds. It is suitable for the plane of various small and medium-sized parts. It is an ideal processing equipment for machinery, electronics, instruments, instruments, molds, automobiles and other industries.

1. The main components such as base, column, workbench, middle slide and lifting slide are all cast from high-strength materials and treated by artificial aging to ensure the stability of long-term use of machine tools, providing stability for machine performance. Guarantee.

2, using high-speed, high-precision, high-rigidity spindle unit, strong carrying capacity, the maximum speed can reach 8000rpm;

3. The X-axis travel of the table is up to 950 mm. The Y and Z-direction guide rails are wide rectangular sliding guides, which are quenched and precision ground by super audio. The sliding guide surface is precisely scraped and coated with composite PTFE material, combined with automatic forced lubrication, reducing the friction resistance of the feed motion, reducing the low speed crawling and improving the precision life of the machine tool.

4. The X, Y and Z three-direction feeds are all made of high-precision, high-strength ball screw and servo motor drive to ensure the positioning accuracy of the machine.

5. The guide rail and ball screw are protected by means to ensure the cleaning of the lead screw and the guide rail to ensure the machine drive and running accuracy.

6. The Z-direction is equipped with a weight balancing device to ensure smooth and smooth movement of the spindle.

7. The electric lubrication device can forcibly lubricate the vertical, horizontal and vertical lead screws and guide rails to reduce the wear of the machine tool and ensure the efficient operation of the machine tool. At the same time, the cooling system can change the size of the coolant flow by adjusting the nozzle to meet different requirements. Processing needs.

8. The machine tool operating system is suspended by the arm at the upper right of the machine tool. It conforms to the ergonomic principle. The operation box can be rotated by a certain angle, and the operation is convenient and reliable.

Specifications:

| CNC VMC milling machine center with automatic tool changer | XH7136 |

| Worktable size | 1250*360mm |

| T-slot | 18/3/80mm |

| Max.loading capacity of worktable | 400kg |

| Worktable travel X*Y*Z | 900*360*480mm |

| Distance between spindle nose to table | 100-600mm |

| Distance between spindle centre to column surface | 460mm |

| Rapid moving speed X/Y/Z | 10/10/8m/min |

| Cutting feeding speed X/Y/Z | 1-6000mm/min |

| Spindle taper | BT40 |

| Max.spindle speed | 8000rpm |

| Spindle motor power | 5.5kw |

| Position accuracy | 0.02 |

| Re-position accuracy | 0.01 |

| Automatic Tool magazine pieces | 16 pcs |

| Time of tool changing | 16 |

| Overall size | 2220*1650*2350mm |

| Machine weight | 3000 kg |

Standard Accessories:

1)Umbrella-type 16 pcs Tools magazine from Taiwan.

2)BT40 spindle unit with 8000rpm spindle unit

3)Full protection

5)Work light

6)Coolant

7)Electric Hand wheel

8)Centralized auto-lubrication system

9) CNC controller