- Product Details

- {{item.text}}

Quick Details

-

Insulation Material:

-

none

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM DLX

-

Model Number:

-

Cr20Ni80, NI80

-

Surface:

-

Bright

-

Condition:

-

Soft

-

Is powder or not:

-

Not Power

-

Certificate:

-

ISO9001,ROHS, TUV

-

Density:

-

8.4g/cm3

-

Resistivity:

-

1.09±0.05

-

Melting point:

-

1400

-

Tensile strength:

-

630-780

-

Elongation:

-

>20

-

Product name:

-

Ni80 cr20ni80 wire 0.1mm 0.32mm nichrome 80 20 heating resistance wire

Quick Details

-

Application:

-

Heating

-

Conductor Material:

-

nickel

-

Conductor Type:

-

Solid

-

Insulation Material:

-

none

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OEM DLX

-

Model Number:

-

Cr20Ni80, NI80

-

Surface:

-

Bright

-

Condition:

-

Soft

-

Is powder or not:

-

Not Power

-

Certificate:

-

ISO9001,ROHS, TUV

-

Density:

-

8.4g/cm3

-

Resistivity:

-

1.09±0.05

-

Melting point:

-

1400

-

Tensile strength:

-

630-780

-

Elongation:

-

>20

-

Product name:

-

Ni80 cr20ni80 wire 0.1mm 0.32mm nichrome 80 20 heating resistance wire

Product Description

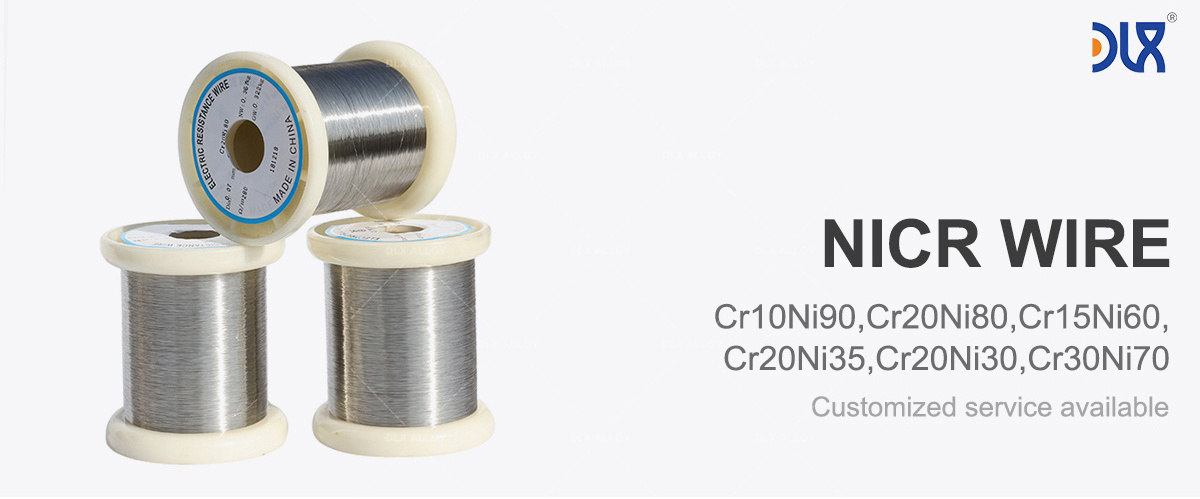

Nichrome wire

Nichrome alloy includes pure nickel, NiCr alloy, Fe-Cr-Al alloy and copper nickel alloy.

Nickel chrome alloys: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni90Cr10, Ni30Cr20, pure nickel Ni200 and Ni201

FeCrAl alloy: 0Cr25Al5, 0Cr23Al5, 0Cr21Al4, 0Cr27Al7Mo2, 0Cr21Al6Nb, 0Cr21Al6.

Copper nickel alloy: CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi23, CuNi30, CuNi44, Constantan,CuMn12Ni

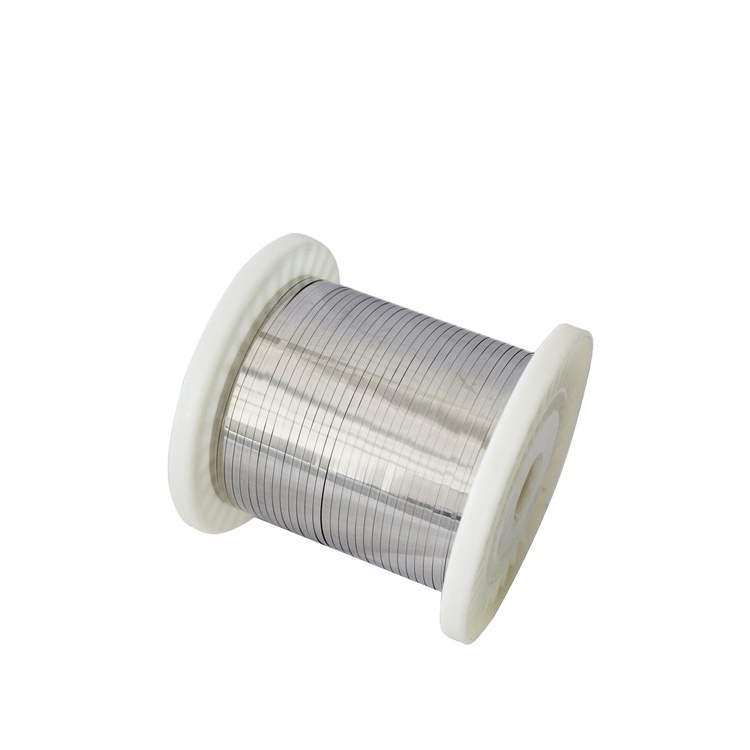

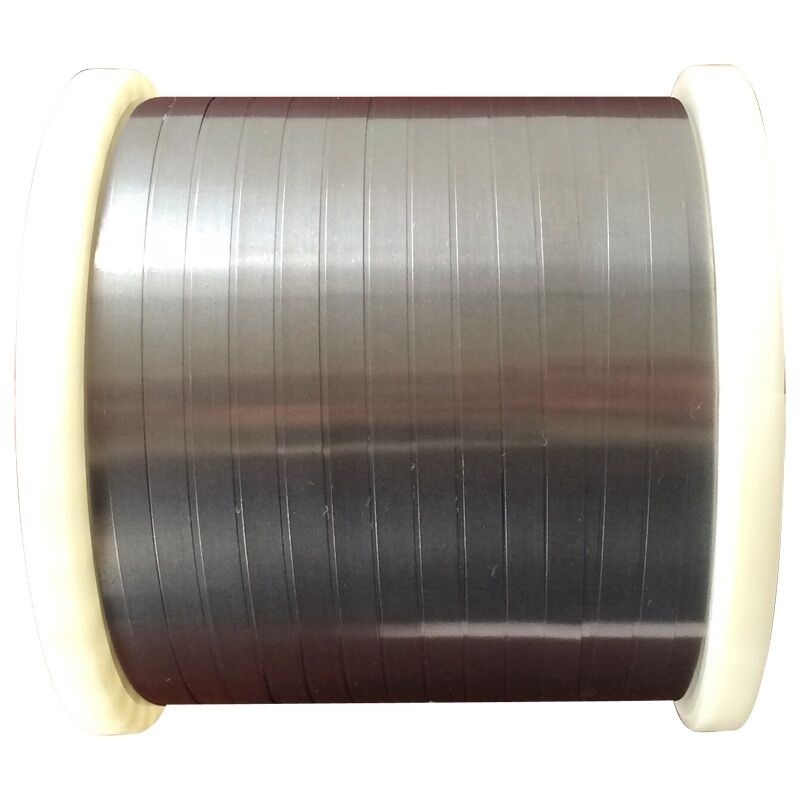

Our Nichrome alloy are in the form of wire, coil, ribbon, strip, foil

Nichrome wire sizes are:

Wire: 0.018mm-10mm

Ribbon: 0.05*0.2mm-2.0*6.0mm

Strip: 0.5*5.0mm-5.0*250mm

Bar: 10-100mm

Nichrome 80 20

Nichrome Grade: Ni70Cr30,Ni80Cr20, Ni60Cr15, Ni35Cr20, Ni30Cr20

NiCr 80/20 also called Chromel A, Cr20Ni80, N8, Nichrome V, HAI - NiCr 80, Tophet A, Resistohm 80, Cronix 80, Protoloy, Alloy A,

MWS-650, Stablohm 650, NCHW1

nicr8020 characteristic

Chemical Content %: 80.00 Nickel, 20.00 Chrome

Max continuous service temperature: 1200ºC

Resisivity: 1.09 mm2Ω /m

Density: 8.4g/cm3

Thermal conductivity: 60.3kj/mhc

Coefficient of thermal expansion: 18*10-6/c

Melting point: 1400ºC

Elongation: Min 20%

Austenite

Nonmagnetic

Nickel chrome alloys: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni90Cr10, Ni30Cr20, pure nickel Ni200 and Ni201

FeCrAl alloy: 0Cr25Al5, 0Cr23Al5, 0Cr21Al4, 0Cr27Al7Mo2, 0Cr21Al6Nb, 0Cr21Al6.

Copper nickel alloy: CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi23, CuNi30, CuNi44, Constantan,CuMn12Ni

Our Nichrome alloy are in the form of wire, coil, ribbon, strip, foil

Nichrome wire sizes are:

Wire: 0.018mm-10mm

Ribbon: 0.05*0.2mm-2.0*6.0mm

Strip: 0.5*5.0mm-5.0*250mm

Bar: 10-100mm

Nichrome 80 20

Nichrome Grade: Ni70Cr30,Ni80Cr20, Ni60Cr15, Ni35Cr20, Ni30Cr20

NiCr 80/20 also called Chromel A, Cr20Ni80, N8, Nichrome V, HAI - NiCr 80, Tophet A, Resistohm 80, Cronix 80, Protoloy, Alloy A,

MWS-650, Stablohm 650, NCHW1

nicr8020 characteristic

Chemical Content %: 80.00 Nickel, 20.00 Chrome

Max continuous service temperature: 1200ºC

Resisivity: 1.09 mm2Ω /m

Density: 8.4g/cm3

Thermal conductivity: 60.3kj/mhc

Coefficient of thermal expansion: 18*10-6/c

Melting point: 1400ºC

Elongation: Min 20%

Austenite

Nonmagnetic

|

Alloy Nomenclature Performance

|

|

Ni80Cr20

|

Ni70Cr30

|

Ni60Cr15

|

Ni35Cr20

|

Ni30Cr20

|

|

|

Main Chemical composition

|

Ni

|

Rest

|

Rest

|

55.0-61.0

|

34.0-37.0

|

30.0-34.0

|

|

|

|

Cr

|

20.0-23.0

|

28.0-31.0

|

15.0-18.0

|

18.0-21.0

|

18.0-21.0

|

|

|

|

Fe

|

≤1.0

|

≤1.0

|

Rest

|

Rest

|

Rest

|

|

|

Max. continuous service temp. of element(ºC)

|

|

1200

|

1250

|

1150

|

1100

|

1100

|

|

|

Resistivity at 20ºC (μΩ·m)

|

|

1.09

|

1.18

|

1.12

|

1.0

|

1.04

|

|

|

Density(g/cm3)

|

|

8.40

|

8.10

|

8.20

|

7.90

|

7.90

|

|

|

Thermal conductivity (KJ/m·h·ºC)

|

|

60.3

|

45.2

|

45.2

|

43.8

|

43.8

|

|

|

Coefficient of lines expansion(α×10-6/ºC)

|

|

18.0

|

17.0

|

17.0

|

19.0

|

19.0

|

|

|

Melting point approx.( ºC)

|

|

1400

|

1380

|

1390

|

1390

|

1390

|

|

|

Elongation at rupture(%)

|

|

>20

|

>20

|

>20

|

>20

|

>20

|

|

|

Micrographic structure

|

|

austenite

|

austenite

|

austenite

|

austenite

|

austenite

|

|

|

Magnetic properties

|

|

nonmagnetic

|

nonmagnetic

|

Weak magnetic

|

Weak magnetic

|

Weak magnetic

|

|

Produce Details

Manufacturing Technique

Appication

The application areas of nickel-chromium alloy strips include:

Petrochemical industry: used to manufacture pipes, valves, pumps and other components in petrochemical equipment, as well as catalyst carriers for petrochemicals.

Aerospace industry:

used to manufacture high-temperature components such as engines, turbine blades, and combustion chambers.

Chemical industry:

used to manufacture reaction kettles, heat exchangers and other components in chemical equipment.

Devices:

used to manufacture devices such as artificial joints and dental implants.

Other fields: such as nuclear industry, electronics industry, etc.

Packing&Shipping

Hot Searches