- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

60*1.4*4.5

-

Weight:

-

60000

-

Power (kW):

-

65

-

Product name:

-

Condom making machine

-

Machine length:

-

60m

-

Machine weight:

-

60T

-

Workshop:

-

80*4.5*5.7m

-

Capacity:

-

1 to 3t dry ballons

-

Workers:

-

5 to 7 persons

-

Power:

-

65kw

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong machinery

-

Voltage:

-

380V/220v

-

Dimension(L*W*H):

-

60*1.4*4.5

-

Weight:

-

60000

-

Power (kW):

-

65

-

Product name:

-

Condom making machine

-

Machine length:

-

60m

-

Machine weight:

-

60T

-

Workshop:

-

80*4.5*5.7m

-

Capacity:

-

1 to 3t dry ballons

-

Workers:

-

5 to 7 persons

-

Power:

-

65kw

Product Description

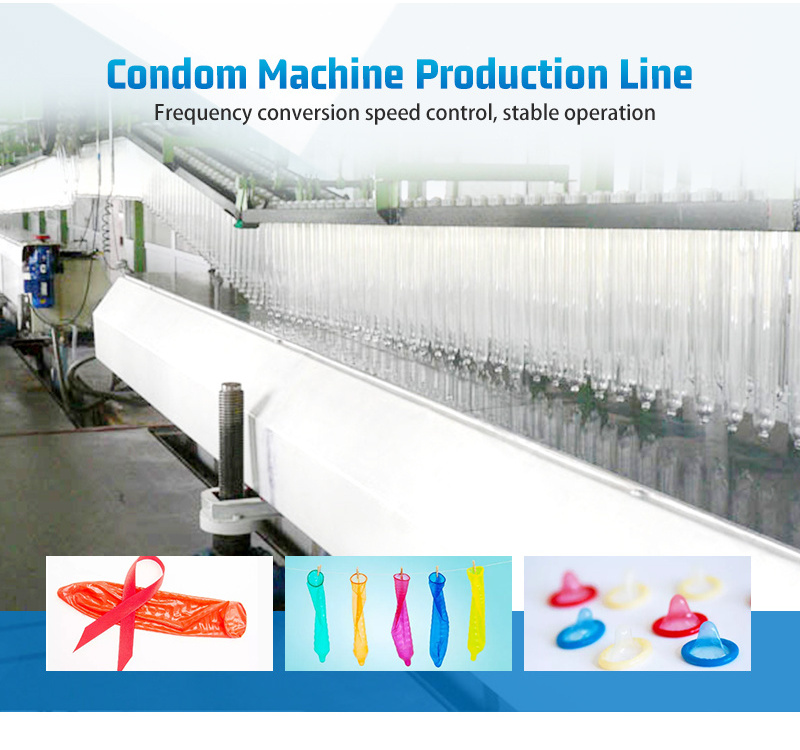

Automatic Good Quality Condom Manufacturing Making Machine

The production process of condoms is not complicated. "At the easternmost end of the workshop, a row of moving transparent glass rods is slowly dipped into a "pool" filled with white latex. The glass rod is a mold. After its outer layer is evenly covered with latex to ensure no gaps, it is dried to become rubber Membrane. The top edge of the rubber membrane is then rolled up and a condom is formed.

From forming to listing, it has to go through layers of "tests": if it is energized in the electrical testing room, if current is generated, it will be unqualified; in the closed blasting room, it will be blown up like a balloon, and if the capacity is less than 18 liters, it will be unqualified; At the water table, it was blown up and filled with water, and if it leaked within a minute, it failed. Finally, a manual inspection is required. Once a defect is found, it will be classified as a defective product.

Specification

Feature of Latex Balloon Production Line for Sale in YG Machinery:

1. The natural latex toy balloon production line adopts continuous production mode and direct dipping mode, the film formation is uniform, the color is gorgeous, various specifications and special-shaped balls can be produced online at the same time, and balloons of various specifications can be produced at the same time; the length of the production line is 35 meters, 40 meters, 60 meters, 80 meters, and other specifications, can be automatically demolded, high output, no-sag products.

2. The machine is humanized according to the process of natural latex solidification and molding. The process is reasonable and the automatic glue filling system is balanced to make the product stable. The thickness of the coating is even and uniform, without sags, uniform temperature, high output, easy demoulding, and so on. Features.

3. The oven adopts the principle of hot air circulation to make the internal temperature of the oven even, and the chemical fiber asbestos insulation material is used to effectively ensure that the temperature is not lost, thereby improving the use of the machine’s thermal efficiency. The machine’s heating system uses a PID temperature intelligent instrument, combined with a high-performance control switch, to improve the accuracy of temperature control, thereby improving the pass rate of products.

4. Specially designed elastic piston mold connection device, easy to change the mold operation, no mold drop phenomenon;

1. The natural latex toy balloon production line adopts continuous production mode and direct dipping mode, the film formation is uniform, the color is gorgeous, various specifications and special-shaped balls can be produced online at the same time, and balloons of various specifications can be produced at the same time; the length of the production line is 35 meters, 40 meters, 60 meters, 80 meters, and other specifications, can be automatically demolded, high output, no-sag products.

2. The machine is humanized according to the process of natural latex solidification and molding. The process is reasonable and the automatic glue filling system is balanced to make the product stable. The thickness of the coating is even and uniform, without sags, uniform temperature, high output, easy demoulding, and so on. Features.

3. The oven adopts the principle of hot air circulation to make the internal temperature of the oven even, and the chemical fiber asbestos insulation material is used to effectively ensure that the temperature is not lost, thereby improving the use of the machine’s thermal efficiency. The machine’s heating system uses a PID temperature intelligent instrument, combined with a high-performance control switch, to improve the accuracy of temperature control, thereby improving the pass rate of products.

4. Specially designed elastic piston mold connection device, easy to change the mold operation, no mold drop phenomenon;

|

Machine Length

|

60M

|

80M

|

100M

|

120M

|

|

Container

|

6PCS

|

8PCS

|

10PCS

|

12PCS

|

|

Production capacity

|

Dry type 1T

|

Dry type 2T

|

Dry type 2.5T

|

Dry type 3T

|

|

Power

|

65KW

|

75KW

|

90KW

|

100KW

|

|

Chain

|

240M

|

320M

|

400M

|

480M

|

Advantages of Balloon Making Machine:

1.This equipment is designed according to the chemical properties of the raw materials and the requirements of the balloon forming process. The process flow is compact and the structure is reasonable.

2.The drying box adopts the tunnel drying method, the principle of hot air rising, and the recycled hot air circulates and stirs so that the machine can get the best effect under the minimum power.

3.This machine makes great use of the effective heating space in the design process, adopts the principle of hot air circulation and intelligent PID temperature control system, and the temperature control is accurate so that the machine can achieve the best energy-saving effect and reduce the cost.

4.High output, unique joint design, simple operation of changing molds, and speeding up the cycle speed.

5.The automatic vibrating glue dispensing and glue dispensing system makes the finished balloon of good quality.

6.Adopt a special high-temperature resistant chain, co-extrusion one-step method, speed up production speed and increase output.

Packing & Delivery

Hot Searches