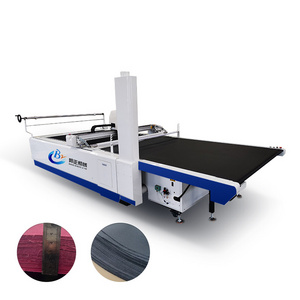

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Textile, leather

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YH

-

Power:

-

22KW

-

Dimension(L*W*H):

-

3750*3200*1500(mm)

-

Weight:

-

3700 KG

-

Features:

-

Automatic

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

cloth cutting machine

-

Key words:

-

Automatic Cutter

-

Cutting materials:

-

cloth,Textile Fabrics, leather...

-

Software:

-

Automatic Cutting System Copyright

-

Item:

-

Cutting Instrument

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

Egypt

-

Certification:

-

CE/ ISO9001

-

Product name:

-

Clothes Cutter Machine

Quick Details

-

Production Capacity:

-

100sets/month

-

Voltage:

-

380V/220V

-

Applicable Industries:

-

Fabric Design, Clothes

-

Application:

-

Textile, leather

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YH

-

Power:

-

22KW

-

Dimension(L*W*H):

-

3750*3200*1500(mm)

-

Weight:

-

3700 KG

-

Features:

-

Automatic

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

cloth cutting machine

-

Key words:

-

Automatic Cutter

-

Cutting materials:

-

cloth,Textile Fabrics, leather...

-

Software:

-

Automatic Cutting System Copyright

-

Item:

-

Cutting Instrument

-

After Warranty Service:

-

Video technical support

-

Local Service Location:

-

Egypt

-

Certification:

-

CE/ ISO9001

-

Product name:

-

Clothes Cutter Machine

Products Description

Automatic Cutting Machine:

Product Features:

1. By adopting computer design and automatic typesetting it saves materials.

2. The computer controls automatic cutting, and it is simple to operate;

3. It can realize zero-space cutting by equipment, which can effectively save raw material;

4. By configuring a dust collection by device. It saves maintenance and service time;

5. It supports multi-source data formats: It directly accepts common apparel design and typesetting software.

6. With high efficiency, energy saving and sectional control, it effectively reduces noise and power;

7. By adopting the unique algonthm and motor control technology, it realize connection for straight line and arcs, and the

cutting accuracy is high;

8. There is no need to print and keep the paper mold, so the repeated utilization factor is high, and it is convenient to carryout platemaking management.

9. It is easy to replace the consumables, and the replacement cost is low;

10. It is high in the degree of automation, the operation is concise, it replaces a high precision, and the sections can be

directly saved without any timing by the lathe workers, which effectively increases the sewing efficiency of the lathe

workers. Automatic Cutting Machine:

Product Features:

1. By adopting computer design and automatic typesetting it saves materials.

2. The computer controls automatic cutting, and it is simple to operate;

3. It can realize zero-space cutting by equipment, which can effectively save raw material;

4. By configuring a dust collection by device. It saves maintenance and service time;

5. It supports multi-source data formats: It directly accepts common apparel design and typesetting software.

6. With high efficiency, energy saving and sectional control, it effectively reduces noise and power;

7. By adopting the unique algonthm and motor control technology, it realize connection for straight line and arcs, and the

cutting accuracy is high;

8. There is no need to print and keep the paper mold, so the repeated utilization factor is high, and it is convenient to carryout platemaking management.

9. It is easy to replace the consumables, and the replacement cost is low;

10. It is high in the degree of automation, the operation is concise, it replaces a high precision, and the sections can be

directly saved without any timing by the lathe workers, which effectively increases the sewing efficiency of the lathe

workers. Automatic Cutting Machine:

Standard Configuration

Intelligent fabric correction

Intelligent fault detection

Intelligent prompt of cutter replacement

Software control for thermal shrinkage of fabrics

Intelligent film re-covering device

Intelligent dust collection and cleaning device

Automatic sharpening and punching

Absorption and bed replacement function

Multiple gears of air exhaust items

Automatic locking of cutter-head Intelligent fabric correction

Intelligent fault detection

Intelligent prompt of cutter replacement

Software control for thermal shrinkage of fabrics

Intelligent film re-covering device

Intelligent dust collection and cleaning device

Automatic sharpening and punching

Absorption and bed replacement function

Multiple gears of air exhaust items

Automatic locking of cutter-head

Intelligent fault detection

Intelligent prompt of cutter replacement

Software control for thermal shrinkage of fabrics

Intelligent film re-covering device

Intelligent dust collection and cleaning device

Automatic sharpening and punching

Absorption and bed replacement function

Multiple gears of air exhaust items

Automatic locking of cutter-head Intelligent fabric correction

Intelligent fault detection

Intelligent prompt of cutter replacement

Software control for thermal shrinkage of fabrics

Intelligent film re-covering device

Intelligent dust collection and cleaning device

Automatic sharpening and punching

Absorption and bed replacement function

Multiple gears of air exhaust items

Automatic locking of cutter-head

Configuration of Electrical Elements:

It adopts accessories imported from japan and German with precision reaching the international standard

It adopts accessories imported from japan and German with precision reaching the international standard

Driver

Frequency converter

Servo Motor

Reducer

Air Cylinder

Guide Rail

Cylinder Components

Switch

Electric wire

Cable Connector Driver

Frequency converter

Servo Motor

Reducer

Air Cylinder

Guide Rail

Cylinder Components

Switch

Electric wire

Cable Connector

Frequency converter

Servo Motor

Reducer

Air Cylinder

Guide Rail

Cylinder Components

Switch

Electric wire

Cable Connector Driver

Frequency converter

Servo Motor

Reducer

Air Cylinder

Guide Rail

Cylinder Components

Switch

Electric wire

Cable Connector

Recommend Products

Why Choose Us

Certifications

Exhibition

FAQ

Q1.How long it’s gonna take to delivery the machine?

A:The machine will be delivered in 45 days since receiving the deposit payment.

Q2.Do your products have warranty period?

A:Yes, for sure; All of our products have one year warranty period.

Q3.How can you guarantee your products?

A:Our products are verified by CE & ISO, so the machine quality can get fully guaranteed.

A:The machine will be delivered in 45 days since receiving the deposit payment.

Q2.Do your products have warranty period?

A:Yes, for sure; All of our products have one year warranty period.

Q3.How can you guarantee your products?

A:Our products are verified by CE & ISO, so the machine quality can get fully guaranteed.

Q4: Are you factory or trading company?

A: We are factory or manufacturer.

Q5: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time.You can be assured on our production completely.

Q6: What should I do if we are not able to operate the machine when we receive it?

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer 's site to solve any problems.

Contact Us

Hot Searches