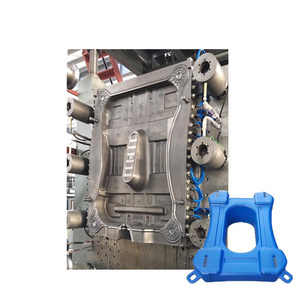

① Low cost, for products of the same size and specifications, the cost of rotary molding molds is about one-third to one-quarter

of the cost of blow molding and injection molding molds.

② The product is formed in one go using the rotational molding process, which is acid and alkali resistant, corrosion-resistant,

wear-resistant, and resistant to impact. It is easy to clean and has good sealing properties, which can protect the content and

items of the product from damage

of the cost of blow molding and injection molding molds.

② The product is formed in one go using the rotational molding process, which is acid and alkali resistant, corrosion-resistant,

wear-resistant, and resistant to impact. It is easy to clean and has good sealing properties, which can protect the content and

items of the product from damage