- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Air Source Heat Pump

-

Storage / Tankless:

-

storage heat **inverter

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SumAir

-

Model Number:

-

ADC-26HCS

-

Function:

-

House Heating /DHW

-

Compressor:

-

Panosonic

-

Refrigerant:

-

R32

-

Heating capacity:

-

25.96kw

-

Power supply:

-

220V~240V/50Hz/60Hz

-

Controller:

-

LED Controller

-

Working Ambient Temperature:

-

Minus 35C-43C

-

Cooling capacity:

-

18.56kw

-

OEM Service:

-

Accept

-

Fan motor:

-

DC Fan Motor

Quick Details

-

Warranty:

-

5 years

-

Application:

-

Outdoor, Hotel, Garage, Commercial, Household

-

Power Source:

-

Electric, Solar

-

Type:

-

Air Source Heat Pump

-

Storage / Tankless:

-

storage heat **inverter

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SumAir

-

Model Number:

-

ADC-26HCS

-

Function:

-

House Heating /DHW

-

Compressor:

-

Panosonic

-

Refrigerant:

-

R32

-

Heating capacity:

-

25.96kw

-

Power supply:

-

220V~240V/50Hz/60Hz

-

Controller:

-

LED Controller

-

Working Ambient Temperature:

-

Minus 35C-43C

-

Cooling capacity:

-

18.56kw

-

OEM Service:

-

Accept

-

Fan motor:

-

DC Fan Motor

Product Features

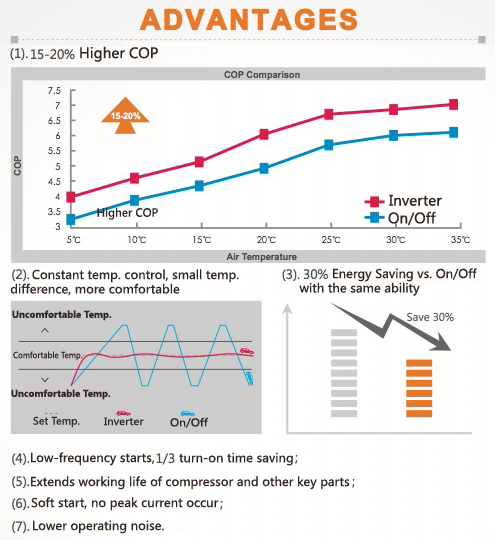

Best SCOP A+++ SG ready controller warm pumpen boiler air source evi split dc inverter heating pump

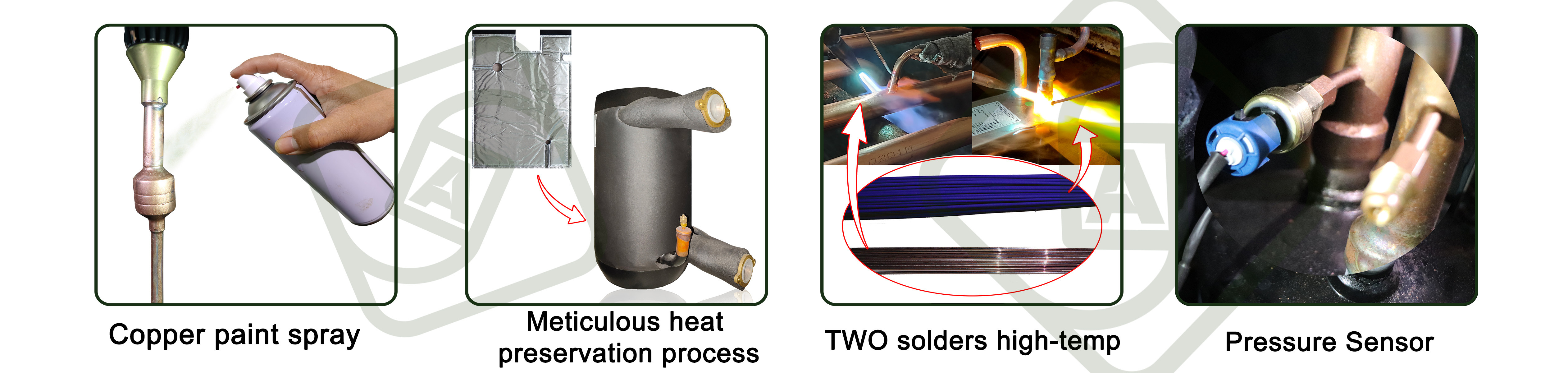

1.Copper paint spray sealing on welding port/soldering point surface, highly anti-rusting & deeply balancing uneven tension by poor welding.

2.Meticulous heat preservation process. High-quality thermal insulation tape combines with high-density Polyeaster rubber-plastic thermal insulation foam, conducting 360°thermal insulation around components & pipes, heat loss in 24H is <4℃ & seals much noise.

3.TWO solders high-temp. welding, fully improving welds' strength to reduce gas leakage. Mysteriouse flux miraculously improves auxiliary heat conduction, removing oxides, reducing welded surface tension & increasing the area, preventing re-oxidation &>2-time prolonging pipeline's life.

4."Pressure Sensor" takes place of Pressure Gauge, not easy to frost, with "pressure", "water flow" & more real-time data can indicates in LED screen.

2.Meticulous heat preservation process. High-quality thermal insulation tape combines with high-density Polyeaster rubber-plastic thermal insulation foam, conducting 360°thermal insulation around components & pipes, heat loss in 24H is <4℃ & seals much noise.

3.TWO solders high-temp. welding, fully improving welds' strength to reduce gas leakage. Mysteriouse flux miraculously improves auxiliary heat conduction, removing oxides, reducing welded surface tension & increasing the area, preventing re-oxidation &>2-time prolonging pipeline's life.

4."Pressure Sensor" takes place of Pressure Gauge, not easy to frost, with "pressure", "water flow" & more real-time data can indicates in LED screen.

Parameter

|

Model

|

|

|

ADC-22HCS

|

ADC-26HCS

|

ADC-32HCS

|

|||||

|

HP

|

|

|

7HP

|

8HP

|

10HP

|

|||||

|

Power Supply

|

|

|

220-240V/50-60Hz/1ph or 380-415V/50-60Hz/3ph

|

|

380-415V/50-60Hz/3ph

|

|||||

|

Heating Condition: Ambient Temp. +7℃/+6℃(WB/DB), Water Temp. +30℃/+35℃(In/Out).

|

|

|

|

|

|

|||||

|

Heating Capacity Rang

|

|

kW

|

6.24-18.85

|

6.43-21.57

|

7.96-26.98

|

|||||

|

Power Input Range

|

|

kW

|

0.96-4.08

|

1.04-4.85

|

1.27-5.96

|

|||||

|

Hot Water Condition: Ambient Temp. +20℃/+15℃ (DB/WB), Water Temp. +15℃/+55℃ (In/Out).

|

|

|

|

|

|

|||||

|

Heating Capacity Rang

|

|

kW

|

6.74-22.66

|

6.97-25.95

|

8.75-32.45

|

|||||

|

Power Input Range

|

|

kW

|

1.33-4.67

|

1.44-5.45

|

1.75-7.76

|

|||||

|

SCOP

|

at 35℃ water outlet

|

|

4.82

|

4.85

|

4.86

|

|||||

|

|

at 55℃ water outlet

|

|

3.45

|

3.54

|

3.50

|

|||||

|

ErP Level

|

at 35℃ water outlet

|

|

A+++

|

A+++

|

A+++

|

|||||

|

|

at 55℃ water outlet

|

|

A++

|

A++

|

A++

|

|||||

|

Heating operation range

|

Ambient

|

°C

|

-30~25

|

|

|

|||||

|

|

Heating side

|

°C

|

18~60

|

|

|

|||||

|

Domestic hot water operation range

|

Ambient

|

°C

|

-30 ~ 43

|

|

|

|||||

|

|

Water side

|

°C

|

25~60

|

|

|

|||||

|

Chilling Condition: Ambient Temp.35℃/30℃ (DB/WB), Water Temp.12℃/7℃(In/Out).

|

|

|

|

|

|

|||||

|

Chilling capacity

|

|

kW

|

4.37-15.95

|

4.83-18.56

|

6.68-23.73

|

|||||

|

Power input range

|

|

kW

|

1.57-5.46

|

1.65-6.23

|

1.93-8.34

|

|||||

|

Chilling operation range

|

Ambient

|

°C

|

10~43

|

|

|

|||||

|

|

Water side

|

°C

|

7~22

|

|

|

|||||

|

Rated water flow rate

|

|

m³/h

|

2.93

|

2.95

|

3.5

|

|||||

|

Rated pressure drop

|

|

kPa

|

45

|

47

|

47

|

|||||

|

Max. working pressure

|

Refrigerant

|

Bar

|

44

|

44

|

44

|

|||||

|

|

Water

|

Bar

|

7

|

7

|

7

|

|||||

|

Controller

|

|

|

Micro processor based digital wire controller, LED Touch Screen

|

|

|

|||||

|

External cabinet

|

|

|

Galvanized steel with powder coating

|

|

|

|||||

|

Compressor

|

Type

|

|

Panasonic Dual Rotary

|

|

|

|||||

|

|

Refrigerant

|

|

R32

|

|

|

|||||

|

Water heat exchanger

|

|

|

SUS 316 Brazed plate heat exchanger

|

|

|

|||||

|

3-Way Valve

|

|

|

HONEYWELL/JOHNSON

|

|

|

|||||

|

Circulation pump

|

|

|

DAB/WILO

|

|

|

|||||

|

Expansion Tank

|

|

|

8L

|

8L

|

10L

|

|||||

|

Water pipe

|

Inlet&Outlet

|

DN

|

32

|

32

|

32

|

|||||

|

Noise in 1Mtr

|

Indoor Unit

|

dB(A)

|

≤31

|

≤32

|

≤33

|

|||||

|

|

Outdoor Unit

|

dB(A)

|

≤58

|

≤59

|

≤61

|

|||||

|

Unit size (W*D*H)

|

Indoor Unit

|

mm

|

550*160*650

|

550*160*650

|

550*160*650

|

|||||

|

|

Outdoor Unit

|

mm

|

1080*470*1400

|

1185*490*1560

|

1185*490*1560

|

|||||

|

Packing size (W*D*H)

|

Indoor Unit

|

mm

|

650*260*750

|

650*260*750

|

650*260*750

|

|||||

|

|

Outdoor Unit

|

mm

|

1180*570*1500

|

1285*590*1660

|

1285*590*1660

|

|||||

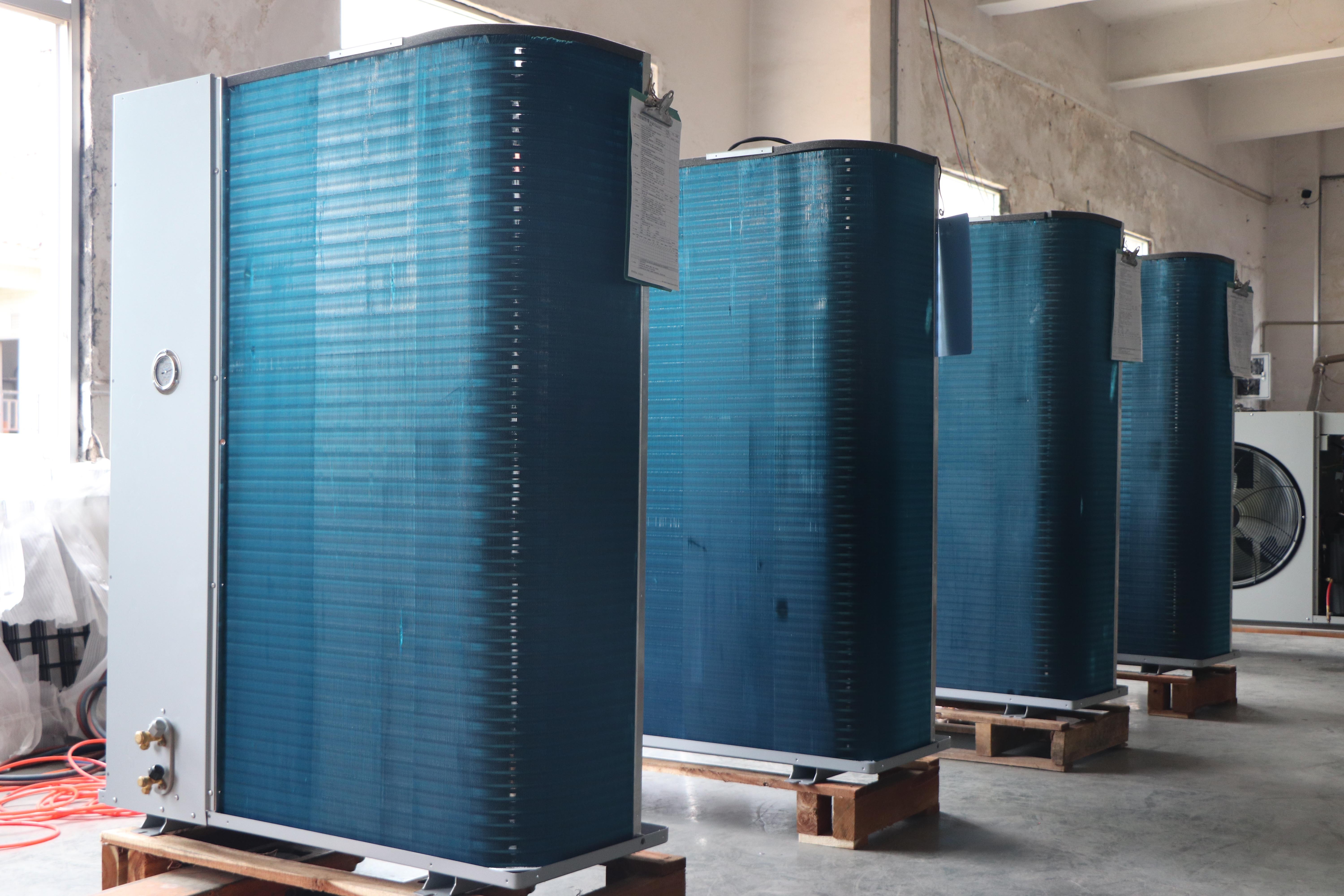

Detailed image

Inner of outdoor unit

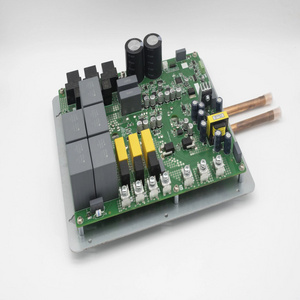

Inner of indoor unit

Working Principle

1. In the heat pump, the evaporator coil is exposed to the outside air.

2. The refrigerant enters the evaporator as a cold liquid/gas mixture at low pressure.

3. Heat from the outside air causes the refrigerant to boil into gas.

4. This gas is pumped through to the condenser coiI by a compressor which also increases the refrigerant’s temperature and pressure.

5. The refrigerant is now hotter than the temperature of the water in the tank, so heat flows out, heating up the water in the

tank and condensing the refrigerant back into a liquid.

6. The refrigerant then flows through an expansion valve that allows the pressure and temperature to drop again by the time it reaches the evaporator coil.

7. Once the refrigerant reaches the evaporator coil the cycle is repeated.

2. The refrigerant enters the evaporator as a cold liquid/gas mixture at low pressure.

3. Heat from the outside air causes the refrigerant to boil into gas.

4. This gas is pumped through to the condenser coiI by a compressor which also increases the refrigerant’s temperature and pressure.

5. The refrigerant is now hotter than the temperature of the water in the tank, so heat flows out, heating up the water in the

tank and condensing the refrigerant back into a liquid.

6. The refrigerant then flows through an expansion valve that allows the pressure and temperature to drop again by the time it reaches the evaporator coil.

7. Once the refrigerant reaches the evaporator coil the cycle is repeated.

Certificates

SG ready Control logic

When Smart Grid Function is set to "Use", the logic is as follows:

A+++ Best SCOP SG ready controller warm pumpen boiler air source evi split dc inverter heating pump

CE Certificate

A+++ Best SCOP SG ready controller warm pumpen boiler air source evi split dc inverter heating pump

ERP Energy Lable

Products in Line

Packages

Application

Recommend Products

Hot Searches