- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Brand Name:

-

Fine-Boon

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Copper, Precious Metals, Stainless steel, Steel Alloys, Kovar

-

Place of Origin:

-

Shanghai

-

Model Number:

-

Customized

-

Brand Name:

-

Fine-Boon

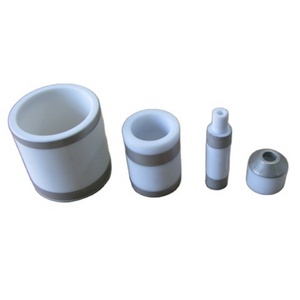

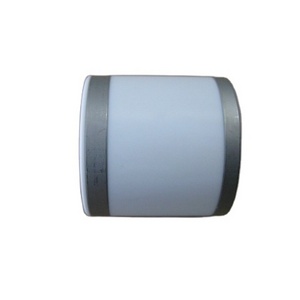

Advanced Precision Machined Kovar Sleeves for Metallized Ceramic Brazing

Kovar alloy is a glass and ceramic sealing metal alloy, it has been used for hetmetic seals with the harder Pyrex glasses and alumina ceramic material.The expansion characteristics of kovar match both glasses and alumina ceramics, making it one of the most popular controlled expansion alloys for hermetic sealing applications. Kovar is produced to ensure good properties for stamping ,machining and deep drawing, and is a porosity free product.

We can make various tailor-made kovar alloy components with high precision with CNC machining centers, they are suitable for brazing with glass or alumina due to similar C.T.E and excellent hermetic sealing result for vacuum fields.We fully understand the quality importance for your brazing result and each part are 100% inspected for dimensions and leaking tests before shipping.

|

|

China Name

|

USA Name

|

|

Germany Name

|

|

|

Standard

|

YB/T5231

|

ASTM

|

UNS

|

W-Nr DIN 17745

|

|

|

Kovar

|

4J29

|

F15

|

K94610

|

1.3981

|

|

|

Product Name

|

Advanced Precision Machined Kovar Sleeves for Metallized Ceramic Brazing

|

|

Material

|

Kovar Alloy - 29% Ni, 17% Co and the balance is Fe

|

|

Color

|

Nickel white

|

|

Standard

|

DIN, GB, ISO, JIS, BA, ANSI, ANS,

|

|

Grade

|

Annealed, 1/4 hard, half hard, 3/4 hard, hard

|

|

Tolerance

|

+/- 0.005 mm

|

|

Thread Types

|

UNC, UNF, UNEF, NPSC, NPT

|

|

Using Fields

|

Feedthrough, Connector, Power tubes, Microwave tubes, Transistors, Diodes, Hybrid packages, and scientific instruments

|

|

Kovar Alloy Chemical Compositions Sheet

- made by Shanghai Fine-Boon

|

|

|

|

|

||||

|

Elements

|

Symbol

|

YB/T 5231

|

ASTM F15

|

DIN 17745

|

||||

|

|

|

4J29

|

K94610

|

1.3981

|

||||

|

Carbon

|

C

|

≤0.03

|

≤0.04

|

≤0.05

|

||||

|

Silicon

|

Si

|

≤0.30

|

≤0.20

|

≤ 0.30

|

||||

|

Manganese

|

Mn

|

≤0.50

|

≤0.50

|

≤0.50

|

||||

|

Phosphorus

|

P

|

≤0.020

|

-

|

-

|

||||

|

Sulphur

|

S

|

≤0.020

|

-

|

-

|

||||

|

Nickel

|

Ni

|

28.5~29.5

|

29.0*

|

28.0~30.0

|

||||

|

Cobalt

|

Co

|

16.8~17.8

|

17.0*

|

16.0~18.0

|

||||

|

Chromium

|

Cr

|

≤0.20

|

≤0.20

|

-

|

||||

|

Copper

|

Cu

|

≤0.20

|

≤0.20

|

-

|

||||

|

Molybdenum

|

Mo

|

≤0.20

|

≤0.20

|

-

|

||||

|

Aluminum

|

Al

|

-

|

≤0.10

|

-

|

||||

|

Magnesium

|

Mg

|

-

|

≤0.10

|

-

|

||||

|

Zirconium

|

Zr

|

-

|

≤0.10

|

-

|

||||

|

Titanium

|

Ti

|

-

|

≤0.10

|

-

|

||||

|

Iron

|

Fe

|

Balance

|

53.0*

|

Rest

|

||||

|

*

:norminal valves, they should be adjusted by the manufacturer so that the alloy meet the requirement for CTE in different temperature range

|

|

|

|

|

||||

Belows are the character sheets for the parts made with kovar alloy, so you can check it for your technical reference

|

Kovar Material Specifications Sheet

-

made by Shanghai Fine-Boon

|

|

|

|

|||

|

No

|

Item

|

Unit

|

Value

|

|||

|

1

|

Kovar Density

|

g/cm

3

|

8.36

|

|||

|

2

|

Melting Temperature

|

℃

|

1450

|

|||

|

3

|

Specific Resistivity

|

Ω mm

2

/ m

|

0.49

|

|||

|

4

|

Electrical conductivity

|

S/m

|

2.174×10

6

|

|||

|

5

|

Thermal Conductivity

|

W/m·K

|

17

|

|||

|

6

|

Specific Heat

|

J/g∙K

|

46

|

|||

|

7

|

Curie Temperature

|

°C

|

435

|

|||

|

8

|

Youngs Modulus

|

Gpa

|

138

|

|||

|

9

|

Elastic Modulus

|

Gpa

|

157

|

|||

|

10

|

Yield Strength-Rp0.2

|

Mpa

|

350

|

|||

|

11

|

Tensile Strength-Rm

|

MPa

|

440-640

|

|||

|

12

|

Elongation Rate-A5

|

%

|

≥25

|

|||

|

13

|

Reduction of Area

|

%

|

30

|

|||

|

14

|

Hardness

|

HRB

|

68*

|

|||

|

* This valve is measured for Kovar material annealed 1830℉ (999℃) for 30 minnutes, then furance cooled

|

|

|

|

|||

|

Coefficient of Thermal Expansion for Kovar as Annealed

- made by Shanghai Fine-Boon

|

|

|

|

|

||||

|

No

|

Temperature Range

|

|

μm/m·℉

|

μm/m·℃

|

||||

|

|

Fahrenheit degree - ℉

|

Celsius degree - ℃

|

|

|

||||

|

1

|

77℉ - 212℉

|

25℃ - 100℃

|

3.25

|

5.86

|

||||

|

2

|

77℉ - 392℉

|

25℃ - 200℃

|

2.89

|

5.20

|

||||

|

3

|

77℉ - 572℉

|

25℃ - 300℃

|

2.85

|

5.13

|

||||

|

4

|

77℉ - 662℉

|

25℃ - 350℃

|

2.72

|

4.49

|

||||

|

5

|

77℉ - 752℉

|

25℃ - 400℃

|

2.81

|

5.06

|

||||

|

6

|

77℉ - 842℉

|

25℃ - 450℃

|

2.92

|

5.25

|

||||

|

7

|

77℉ - 932℉

|

25℃ - 500℃

|

3.41

|

6.15

|

||||

|

8

|

77℉ - 1112℉

|

25℃ - 600℃

|

4.34

|

7.80

|

||||

|

9

|

77℉ - 1292℉

|

25℃ - 700℃

|

5.06

|

9.12

|

||||

|

10

|

77℉ - 1472℉

|

25℃ - 800℃

|

5.73

|

10.31

|

||||

|

11

|

77℉ - 1652℉

|

25℃ - 900℃

|

6.25

|

11.26

|

||||

|

* Kovar material annealed 1830℉ (999℃) for 30 minnutes, then furance cooled

|

|

|

|

|

||||

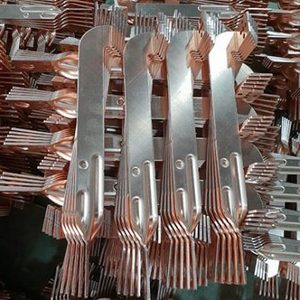

Factory Birdivew

Workshops View

Our workshop for various machined kovar sleeves production

Packing Details: PE blister shell for each machined kovar sleeve, seaworthy packing in paper carton

Delivery Details: 30 days after order of machined machined sleeves was issued

1. Blister shell packed for each machined kovar sleeve separately in carton

2. All cartons are loaded in Ply-wood standard pallets with films wraped.

3. All shipping methods are available for your choice.

Q: Are you a trading company or manufacturer ?

A: We are a professional CNC machining factory with our own exporting office in Shanghai

Q: How long is your delivery time for customized machined kovar sleeves?

A: Generally it is 30 days after your P/O issued to us , it is according to quantity.

Q: Do you provide samples of machined kovar sleeve? is it free or charged?

A: Yes, we could offer the machined kovar sample for free, but don't afford freight.

Q: What is your terms of payment for kovar sleeves?

A: Payment<=1000 USD, 100% in advance.

Payment>=1000 USD, 30% T/T in advance ,balance before shipment.

If you have any other question for machined metal parts, please feel free to contact us as below: