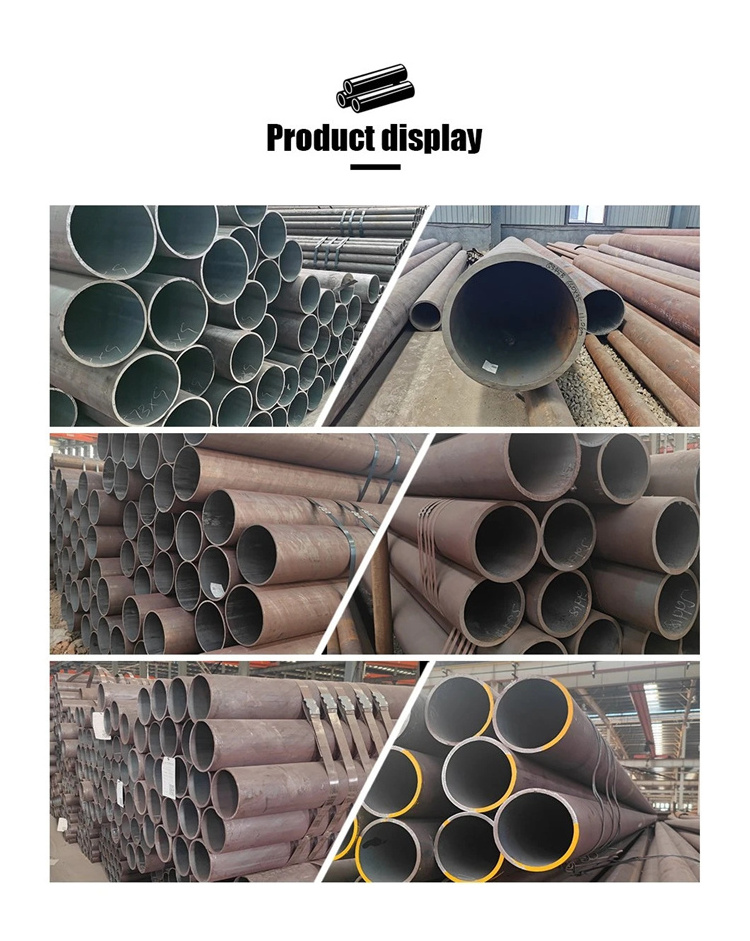

- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Great Steel

-

Outer Diameter:

-

32 - 630 mm

-

Thickness:

-

3mm-180mm

-

Length:

-

6m, Random Length or Fixed Length

-

Grade:

-

SAE1020,4130 SA210C,DIN17175,ASME SA213,ASME SA210

-

Keyword:

-

Alloy Steel Tube

-

MOQ:

-

1 Ton

-

End protector:

-

Plastic Pipe Cap Iron Protector

-

Payment Term:

-

T/T L/C(30% Deposite)

-

PRICE TERM:

-

CIF FOB CNF EXW

-

Sample:

-

Sample Freely

-

Inspection:

-

Accept Thirdparty Inspection

-

Surface:

-

Customers' Demand

-

Secondary Or Not:

-

First-class Meterial

-

Steel Grade:

-

12Cr1MoVG 20# 45# 16Mn,20G Cr9Mo 10CrMo910 15Mo3 15CrMoV

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

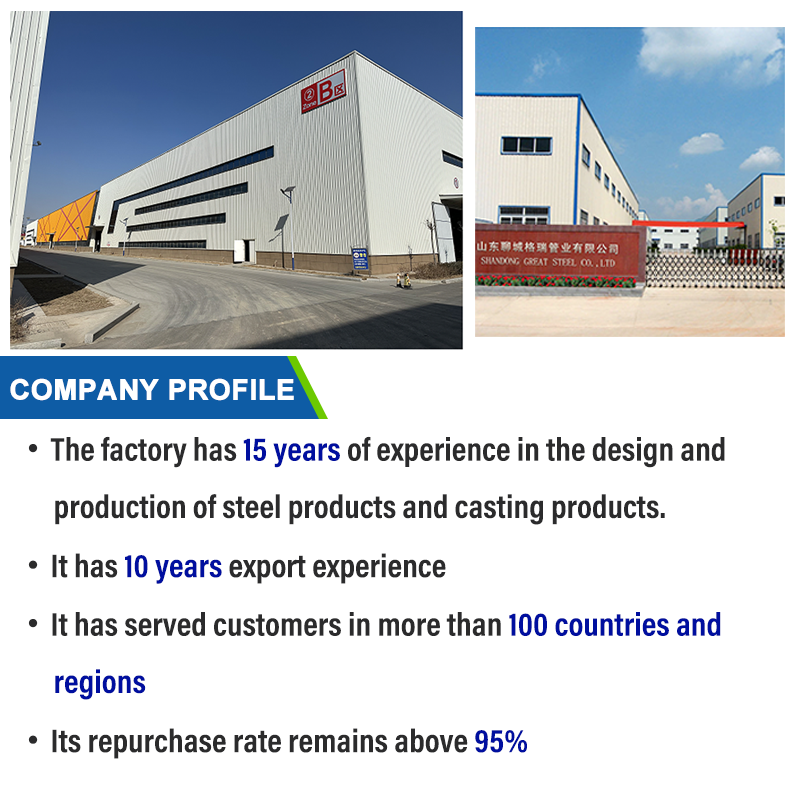

Shandong, China

-

Brand Name:

-

Great Steel

-

Outer Diameter:

-

32 - 630 mm

-

Thickness:

-

3mm-180mm

-

Length:

-

6m, Random Length or Fixed Length

-

Grade:

-

SAE1020,4130 SA210C,DIN17175,ASME SA213,ASME SA210

-

Keyword:

-

Alloy Steel Tube

-

MOQ:

-

1 Ton

-

End protector:

-

Plastic Pipe Cap Iron Protector

-

Payment Term:

-

T/T L/C(30% Deposite)

-

PRICE TERM:

-

CIF FOB CNF EXW

-

Sample:

-

Sample Freely

-

Inspection:

-

Accept Thirdparty Inspection

-

Surface:

-

Customers' Demand

-

Secondary Or Not:

-

First-class Meterial

-

Steel Grade:

-

12Cr1MoVG 20# 45# 16Mn,20G Cr9Mo 10CrMo910 15Mo3 15CrMoV

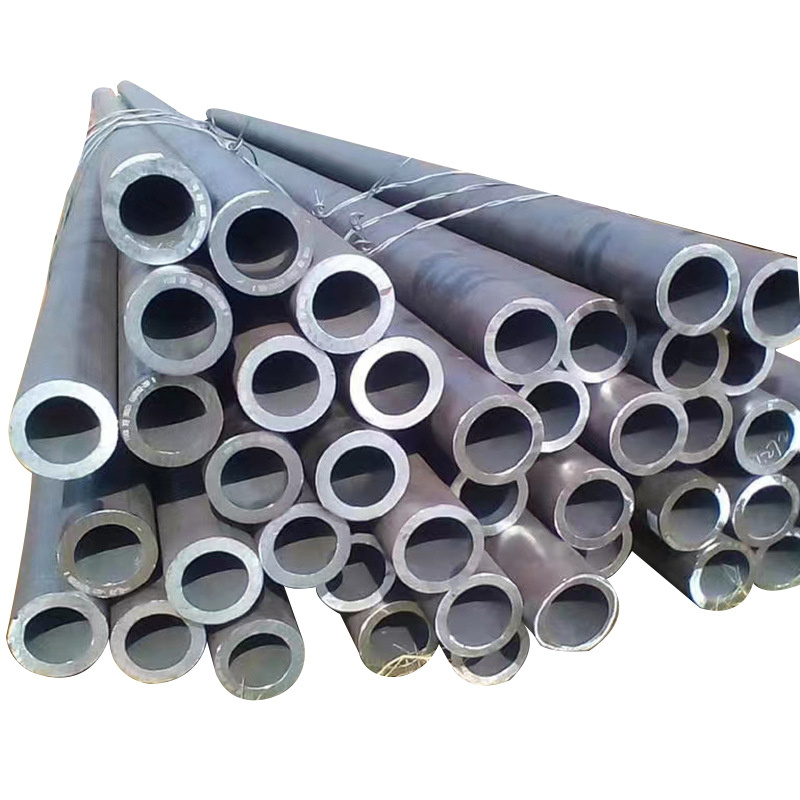

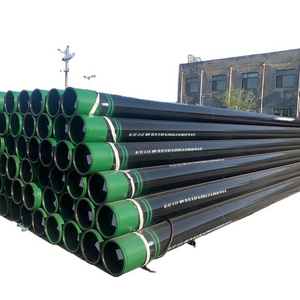

Seamless alloy pipes are a type of pipes made from alloy materials that do not have any welded seams. These pipes are commonly used in industries that require high strength and resistance to corrosion, such as oil and gas, chemical, and power generation industries.

The seamless manufacturing process involves heating a solid billet of alloy material and then piercing it with a mandrel to create a hollow pipe. The pipe is then elongated and rolled to achieve the desired size and shape. This process ensures a uniform and consistent structure throughout the pipe, resulting in high-quality and reliable products.

One of the main advantages of seamless alloy pipes is their superior strength. The absence of welds eliminates the weak points that can be found in welded pipes, making them more resistant to pressure and stress. This makes seamless alloy pipes ideal for applications that require high pressure and temperature, such as steam boilers and heat exchangers.

Seamless alloy pipes also offer excellent resistance to corrosion. The alloy materials used in their production, such as stainless steel, nickel alloys, and titanium, have inherent corrosion resistance properties. This makes seamless alloy pipes suitable for transporting corrosive fluids and gases in harsh environments.

In addition, seamless alloy pipes have a smooth interior surface, which allows for efficient flow of fluids and minimizes pressure loss. This is especially important in industries where the flow of fluids needs to be optimized, such as in oil and gas pipelines.

Overall, seamless alloy pipes are a reliable and durable solution for various industrial applications. Their high strength, corrosion resistance, and smooth interior surface make them a preferred choice for industries that req

|

Standard |

ASTM A213 T5 A209 T1 A335 P11 P22 P5 alloy steel pipe AP175-79, DIN2I5L , ASTM A106 Gr.B, ASTM A53 Gr.B, ASTM A179/A192/A213/A210 /370 WP91, WP11,WP22. DIN17440, DIN2448,JISG3452-54, DIN 17175 . |

|

Material |

15CrMoG,12Cr2MoG,12Cr1MoVG,12Cr2MoWVTiB,10Cr9Mo1VNb,SA210A1,SA210C,SA213 T11,SA213 T12,SA213 T22,SA213 T23,SA213 T91,SA213 T92,ST45.8/Ⅲ,15Mo3,13CrMo44,10CrMo910,16Mn 12Cr1MoV T91 27SiMn 30CrMo 15CrMo 20G Cr9Mo 10CrMo910 15Mo3 15CrMoV 35CrMoV 45CrMo |

|

Certificates |

API5L ISO 9001:2008 TUV SGS BV etc |

|

Outside Diameter |

1/2'--24' |

|

32mm-630mm |

|

|

Thickness |

SCH5S, SCH10S, SCH20S,SCH20, SCH30,STD, SCH40, SCH60, SCH80, SCH100, SCH140, SCH160,XS, |

|

1.65mm-59.54mm |

|

|

Length |

5.8m 6m Fixed, 12m Fixed, 2-12m Random. |

|

Technic |

1/2'--6': hot piercing processing technic |

|

6'--24' : hot extrusion processing technic |

|

|

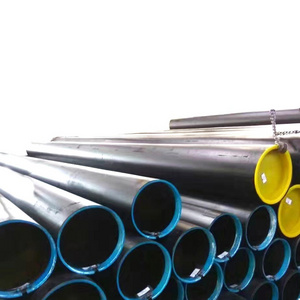

Surface Treatment |

Black Painted, Galvanized, Natural, Anticorrosive 3PE coated,polyurethane foam Insulation . |

|

Packing |

Bundles or In bulk. bundled pipes with two slings at the both end for easy loading and discharging, |

|

End |

Bevel end(>2"), Plain (≤2"),with plastic cap, with screwed and socket. |