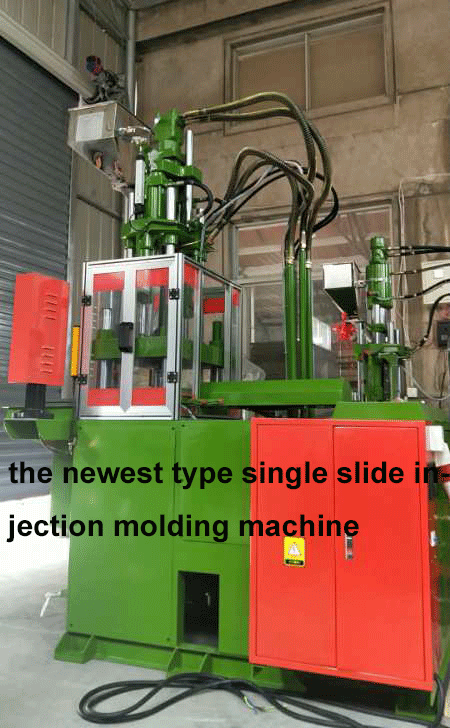

- Product Details

- {{item.text}}

Quick Details

-

Ejector Stroke(mm):

-

135 mm

-

Ejector Force(kN):

-

48 kN

-

Theoretical Shot Volume(cm³):

-

288 cm³

-

Injection Rate (g/s):

-

138 g/s

-

Injection Weight (g):

-

260 g

-

Screw Speed (rpm):

-

1 - 180 rpm

-

Screw diameter (mm):

-

48 mm

-

Screw L/D Ratio:

-

26

-

Distance between Tie Bars:

-

630*400mm

-

Weight (KG):

-

5150

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

300 mm

-

Model Number:

-

CY-1000ST-D-PP

-

Brand Name:

-

Zanyang

-

Power (kW):

-

14.5 kW

-

Opening stroke:

-

300mm

-

Clamping force:

-

120Tons

-

Injection Weight:

-

9.3OZ

-

Pump motor power:

-

14.5KW/22HP

-

Min. mold height:

-

580/280mm

-

Ejetor Force:

-

4.8 Tons

-

Screw speed:

-

180rpm

-

Injection pressure:

-

1125kg/cm3

-

Total Weight:

-

20KW

-

Injection Rate:

-

200

-

Certification:

-

CE ISO9001

Quick Details

-

Plasticizing Capacity(g/s):

-

118

-

Mold Height(mm):

-

280 - 580 mm

-

Ejector Number:

-

3

-

Ejector Stroke(mm):

-

135 mm

-

Ejector Force(kN):

-

48 kN

-

Theoretical Shot Volume(cm³):

-

288 cm³

-

Injection Rate (g/s):

-

138 g/s

-

Injection Weight (g):

-

260 g

-

Screw Speed (rpm):

-

1 - 180 rpm

-

Screw diameter (mm):

-

48 mm

-

Screw L/D Ratio:

-

26

-

Distance between Tie Bars:

-

630*400mm

-

Weight (KG):

-

5150

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

300 mm

-

Model Number:

-

CY-1000ST-D-PP

-

Brand Name:

-

Zanyang

-

Power (kW):

-

14.5 kW

-

Opening stroke:

-

300mm

-

Clamping force:

-

120Tons

-

Injection Weight:

-

9.3OZ

-

Pump motor power:

-

14.5KW/22HP

-

Min. mold height:

-

580/280mm

-

Ejetor Force:

-

4.8 Tons

-

Screw speed:

-

180rpm

-

Injection pressure:

-

1125kg/cm3

-

Total Weight:

-

20KW

-

Injection Rate:

-

200

-

Certification:

-

CE ISO9001

Product Description

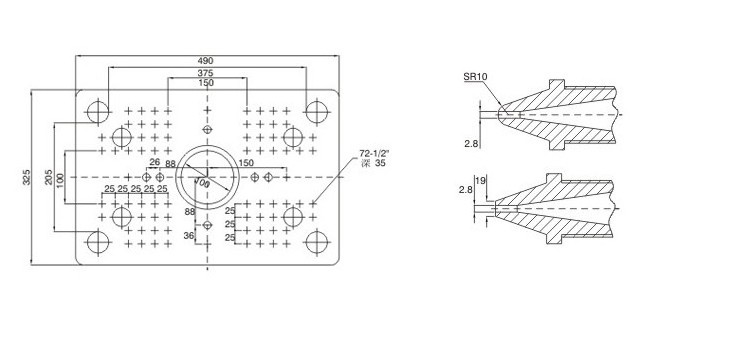

Main Features

1) Simple structure in linear type, easy in installation and maintenance.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts, and operation parts.

3) High-pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization, no pollution

5) Apply a linker to connect with the air conveyor, which can directly in line with filling machine.

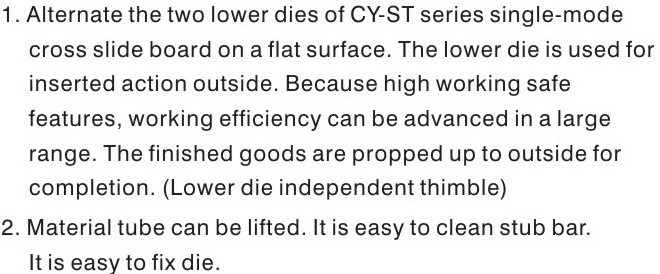

Chart

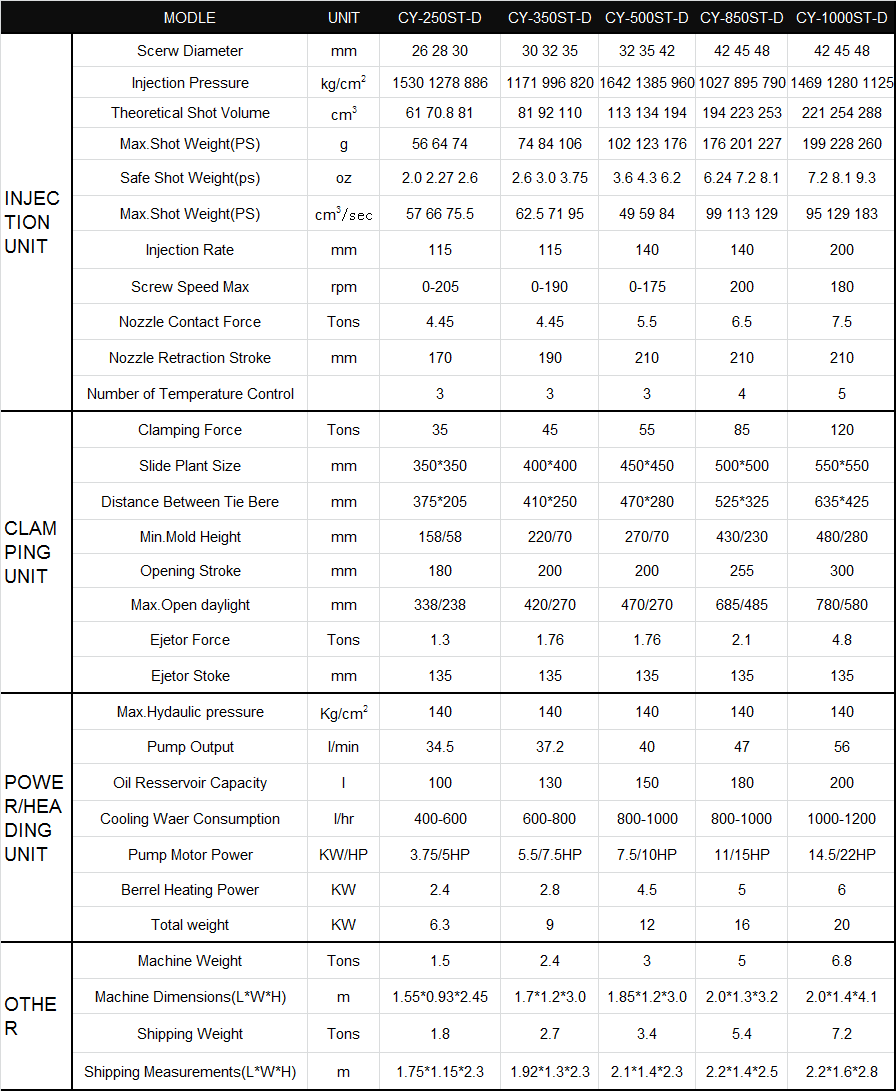

Detailed Images

Product Image

Hot Searches