- Product Details

- {{item.text}}

Quick Details

-

Material:

-

EPP

-

Product name:

-

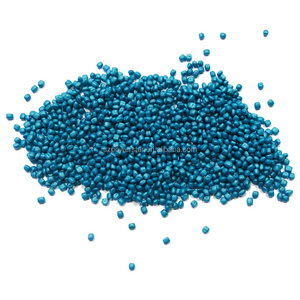

EPP Beads Foam Raw Material

-

Color:

-

Customized color

-

Shape:

-

Circular

-

Density:

-

10-90g/l

-

Usage:

-

General Plastics

-

MOQ:

-

25kg

-

Keyword:

-

EPP

-

Type:

-

Virgin Plastic Raw Resin

-

Application:

-

Food Packeging

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Hanwell

-

Model Number:

-

EPP raw material

-

Material:

-

EPP

-

Product name:

-

EPP Beads Foam Raw Material

-

Color:

-

Customized color

-

Shape:

-

Circular

-

Density:

-

10-90g/l

-

Usage:

-

General Plastics

-

MOQ:

-

25kg

-

Keyword:

-

EPP

-

Type:

-

Virgin Plastic Raw Resin

-

Application:

-

Food Packeging

Products Description

|

Product Name

|

EPP raw material

|

|

Material

|

Epp

|

|

Color

|

Customized color

|

|

Shape

|

spherical

|

|

Density

|

10-90g/l

|

|

MOQ

|

1000kgs

|

|

Advantage

|

1.More than 20 years experience on EPP,EPS,Molded pulp, plastic packaing ;

2. With a lot of advanced forming equipment;

3.Realized the highly vertically integrated from the raw material to the final products; 4. With a lot of experience on working with the world-class customers from all over the world |

WHAT IS EPP RAW MATERIAL?

Expanded Polypropylene (EPP) is a closed-cell foam known for its flexible and lightweight properties. We provide quality EPP to an impressive list of automotive Tier 1 and Tier 2 customers. The platen sizes of our machines range from 600 × 800 mm to 1,300 x1,700 mm.

EPP’s high energy absorbent properties combined with characteristic lightness make it a vital material in various industries. EPP is unchangeable after multiple impact loading and repetitive shocks which is why it recovers remarkably after dynamic and static loading. Its distinct properties of high sound absorption, low water absorption, and excellent chemical resistance have further fuelled its use in various fields.

High thermal resistance allows EPP to provide optimum heat insulation. Furthermore, EPP does not support microbial growth and can be made sterile with steam cleaning. This makes it appropriate for use in containers for food and beverages. However, the most distinctive features of EPP are its ecological properties. EPP is 100% non-toxic as it does not contain CFCs or any other blowing agents, making it an environmentally-friendly product. EPP can also be recycled easily.

Why We Choose EPP?

EPP has become the fastest growing new type of environmental protection heat insulation material. Its products have excellent seismic energy absorption performance, high recovery rate after deformation, good heat resistance, chemical resistance, oil resistance and heat insulation, in addition, its light weight, can greatly reduce the weight of articles. EPP is also an environmental protection material, not only can be recycled, but also can be natural degradation, will not cause white pollution.

What Can EPP Do?

EPP is widely utilised by many manufacturers because of its performance benefits for energy management, lightweight,enhanced functionality, durability and recyclability. Applications include seating, bumpers, stowage systems, door panels,pillars, floor levelers, parcel shelves, head rests, tool kits, sun visors and myriad filler parts...

kids toys

sports entertainment

household production

cooler box

baby protective gear

auto parts

EPP pallet

EPP helmet

bee box

How To Process EPP?

The manufacturing process is complex, requiring both technical expertise and specialised custom equipment. Polypropylene resin is combined with other ingredients in a multi-step proprietary process. Under tightly controlled conditions, extruded pellets expand to become consistently shaped beads of expanded polypropylene foam. Other specialised manufacturing techniques may be employed to produce variations in the final product form.

EPP foam beads are then injected into molds. In many cases, cost-effective multi-cavity aluminum molds are used. Pressure and steam heat fuse the beads into a finished shape. The finished EPP foam part becomes a key component in sub-assemblies incorporated in the original equipment manufacturer’s product.

EPP foam beads are then injected into molds. In many cases, cost-effective multi-cavity aluminum molds are used. Pressure and steam heat fuse the beads into a finished shape. The finished EPP foam part becomes a key component in sub-assemblies incorporated in the original equipment manufacturer’s product.

Production Detail

00

Products Real Shot

More Products

FAQ

Q1:Are you a manufacturer or trading company?

We are one of biggest professional manufacturer in packing industry, own two production bases in Shandong province, with 100,000 square meters.

Q2:Is your material eco-friendly?

The main materials we used are EPP, EPE, EPTU foam,Paper or plastic, All material is eco-friendly.

Q3: What’s the price of your products?

Exact price is based on your design and quantity.If you could send us specific demand, we will glad to quote best price for your reference.

Q4:How much the tool cost & mold charges for new design?

The exact charge is based on design solution, in general, it’s about USD 6000 to USD 10000.

Q5: Can we get free sample and free freight?

If the sample which we have mold, it’s free and shipping freight will paid by receiver. If customized sample, mold fee is about USD5000- USD 8000 and delivery time is 4-5 weeks.

Q6: What’s your payment terms?

1. T/T: order below USD5000, we prefer to T/T 100% in advance. order is large amount, T/T 30% in advance, the balance against by the copy of B/L. 2. Letter of Credit 100% at sight 3. Western Union: Small amount and freight 4.Alibaba Assurance is available for us.

Q7: What’s your MOQ?

Q7: What’s your MOQ?

MOQ depends on the products, usually it is 1,000kg for raw material, 300pcs for finished products.

Q8: Whether you could make our brand on your products?

That's no problem

Q8: Whether you could make our brand on your products?

That's no problem

Hot Searches