- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220/380V

-

Power:

-

0.15-75kw

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

500 KG

-

Output product name:

-

tomato paste

-

Product name:

-

Multifunctional Fruit Processing Machine

-

Application:

-

Commercial Juicer Extractor

-

Material:

-

304 Stainless Steel

-

Capacity:

-

500kg/h

-

MOQ:

-

1 Set

-

Package:

-

Wooden Case

-

Color:

-

Stainless Steel Color

-

Final product:

-

Fruit Jam Puree Pulp

-

Feature:

-

High Efficient

-

Advantage:

-

Easy Operation

Quick Details

-

Raw material:

-

Fruit, Vegetables

-

Model Number:

-

Antler-500

-

Brand Name:

-

Antler

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220/380V

-

Power:

-

0.15-75kw

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

500 KG

-

Output product name:

-

tomato paste

-

Product name:

-

Multifunctional Fruit Processing Machine

-

Application:

-

Commercial Juicer Extractor

-

Material:

-

304 Stainless Steel

-

Capacity:

-

500kg/h

-

MOQ:

-

1 Set

-

Package:

-

Wooden Case

-

Color:

-

Stainless Steel Color

-

Final product:

-

Fruit Jam Puree Pulp

-

Feature:

-

High Efficient

-

Advantage:

-

Easy Operation

Product Description

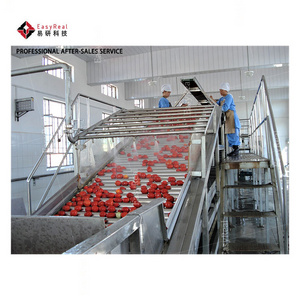

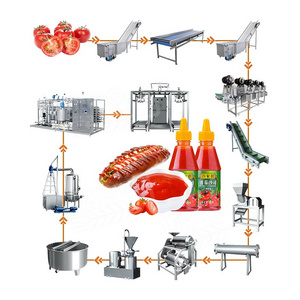

Tomato paste production line

The working principle of the tomato paste production line is to make concentrated tomato paste and fill it into packages after a series of processes such as cleaning, selecting, crushing, boiling, mixing and filling.Tomato paste production lines are generally used in juice jam processing, condiment processing factories, jam re-processing enterprises, etc.

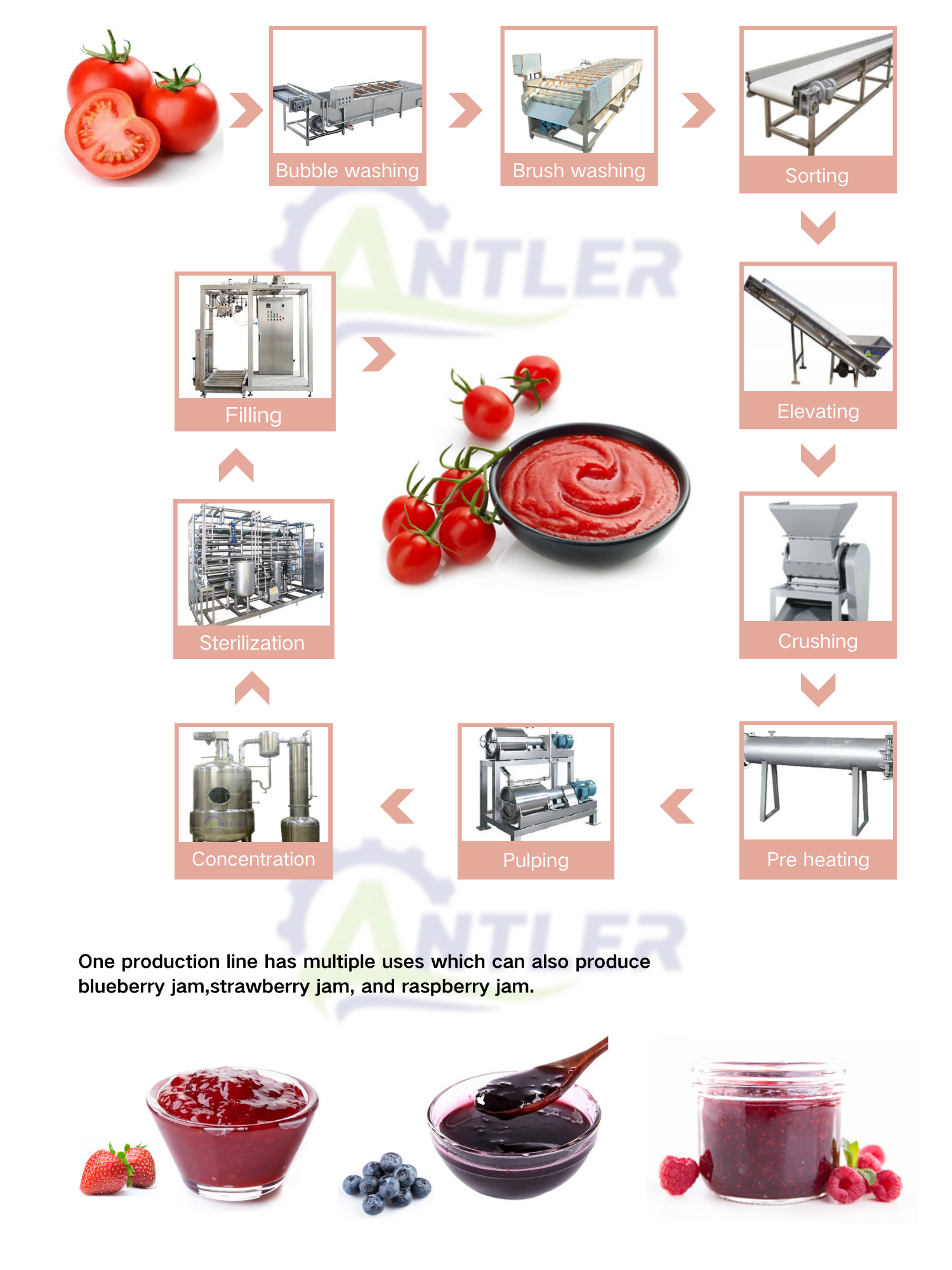

Production Process

Filling & Packing system

As per request package and packing size, we shall offer you the filling and packing machine accordingly.

Application

Product details

Specification

|

No.

|

Equipment Name

|

Function

|

|

1

|

Picking Belt

|

Manually remove unqualified, worm-eye, and moldy tomatoes

|

|

2

|

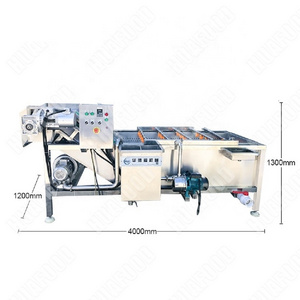

Tomato Washing Machine

|

Under the action of bubbles and spray, the picked tomatoes are cleaned.mainly to remove the surface sediment

|

|

3

|

Tomato Crushing Machine

|

Crush the washed tomatoes to facilitate the later beating work

|

|

4

|

Tubular Preheater

|

Increase temperature of slurry to achieve preheating, inactivating enzymesand protecting color

|

|

5

|

Tomato Pulping Machine

|

Pitting and beating fruits after pre-cooking

|

|

6

|

Buffer Tank

|

|

|

7

|

Concentrator

|

|

|

8

|

Tubular sterilizer

|

Sterilization of concentrated tomato paste

|

|

9

|

Finished tank

|

Ketchup after sterilization

|

|

10

|

Packing Machine

|

Ketchup packaging work

|

Small capacity Flow chart

Large capacity Flow chart

Similar Products

Hot Searches