- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Max. Weight of Workpiece(kg):

-

400

-

Spindle Bore(mm):

-

82

-

Width of bed (mm):

-

600 mm

-

Spindle Motor Power(kW):

-

11

-

Max. Turned Length (mm):

-

400

-

Travel (X Axis)(mm):

-

260 mm

-

Travel (Z Axis)(mm):

-

550 mm

-

Positioning Accuracy (mm):

-

0.008

-

Repeatability (X/Y/Z) (mm):

-

0.004

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

2650*2050*2050mm

-

Brand Name:

-

Hanover

-

Model Number:

-

CKX500L

-

Voltage:

-

380v

-

Weight (KG):

-

3600

-

CNC or Not:

-

CNC

-

Automatic Grade:

-

Automatic

-

Machine Type:

-

Slant Bed Cnc Lathe Machine

-

Turret Type:

-

12 position servo turret

-

Chuck:

-

Hydraulic 3 jaw hollow chuck

-

Spindle:

-

Taiwan spindle unit

-

Spindle speed:

-

2000rpm/min

-

Spindle motor:

-

CTB servo motor

-

Tailstock:

-

Hydraulic

-

CNC control:

-

Siemens/Fanuc

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

500

-

Year:

-

2024

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Max. Weight of Workpiece(kg):

-

400

-

Spindle Bore(mm):

-

82

-

Width of bed (mm):

-

600 mm

-

Spindle Motor Power(kW):

-

11

-

Max. Turned Length (mm):

-

400

-

Travel (X Axis)(mm):

-

260 mm

-

Travel (Z Axis)(mm):

-

550 mm

-

Positioning Accuracy (mm):

-

0.008

-

Repeatability (X/Y/Z) (mm):

-

0.004

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

2650*2050*2050mm

-

Brand Name:

-

Hanover

-

Model Number:

-

CKX500L

-

Voltage:

-

380v

-

Weight (KG):

-

3600

-

CNC or Not:

-

CNC

-

Automatic Grade:

-

Automatic

-

Machine Type:

-

Slant Bed Cnc Lathe Machine

-

Turret Type:

-

12 position servo turret

-

Chuck:

-

Hydraulic 3 jaw hollow chuck

-

Spindle:

-

Taiwan spindle unit

-

Spindle speed:

-

2000rpm/min

-

Spindle motor:

-

CTB servo motor

-

Tailstock:

-

Hydraulic

-

CNC control:

-

Siemens/Fanuc

CNC Turning Lathe Mill Combo CKX500L Taiwan CNC Lathe with C-Axis

1.Taiwan Taizheng Heavy duty 45 degree bed structure,more stable and high precision.

2. Adopt independent tube in tube structure spindle unit, equip with dedicated bearing of high-precision spindle, adopt special lubricating greases to lubricate. Decrease greatly thermal deformation of spindle unit, increase thermal stability and accuracy of spindle unit.

3. Famous brands’ developed products are all adopted for CNC systems and drive units. With years’ application, PLC is safe and reliable. The electrical apparatuses are all European brand products with low malfunction rate and long lasting durability.

4. With delicate machine tools assembly techniques and precision correction by laser interferometers and laser ball bars, its mechanical accuracy is far higher than that of the international.

CNC Turning Lathe Mill Combo CKX500L Taiwan CNC Lathe with C-Axis Specifications:

| Item | CKX500L CNC Lathe |

| Max.swing over bed(mm) | 530 |

| Distance of the centre(mm) | 370 |

| Max.travel of X/Z axis(mm) | 260/550 |

| Rapid moving speed of X/Z axis(m/min) | 24/18 |

| Spindle motor power (KW) | 11/15 |

| Max.rotational speed of spindle(rpm/min) | 2000 |

| Spindle type | A2-8 |

| Spindle bore(mm) | 82 |

| Chuck size(inch) | 10 |

| Center height of servo turret(mm) | 100 |

| Cutter numbers of the hydraulic tool turret | 12 |

| Tailstock diameter/taper | 75/MT5 |

| Tailstock Bush's travel(mm) | 80 |

| Positioning accuracy of X/Z axis (mm) | ±0.008 |

| Repositioning accuracy(mm) | ±0.004 |

| Surface roughness(mm) | ≤0.001 |

| External dimension(L*W*H)(mm) | 3100*2150*2050 |

| Weight(kg) | 3600 |

Pictures of CNC Turning Lathe Mill Combo CKX500L Taiwan CNC Lathe with C-Axis

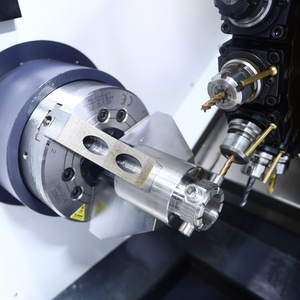

1.The overview of CKX500L CNC lathe

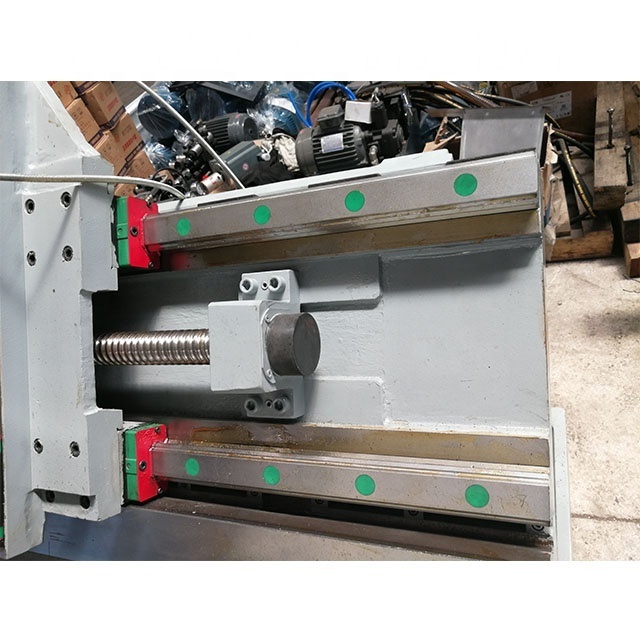

2.The machine frame of CKX500L CNC lathe

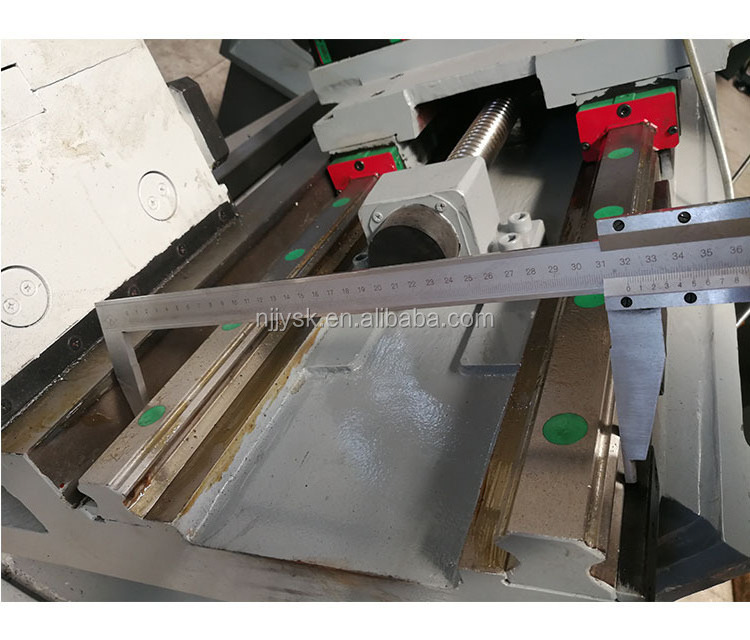

3.Z axis linear rails' width of CKX500L CNC lathe

4.The X axis linear rails' width of CKX500L CNC lathe

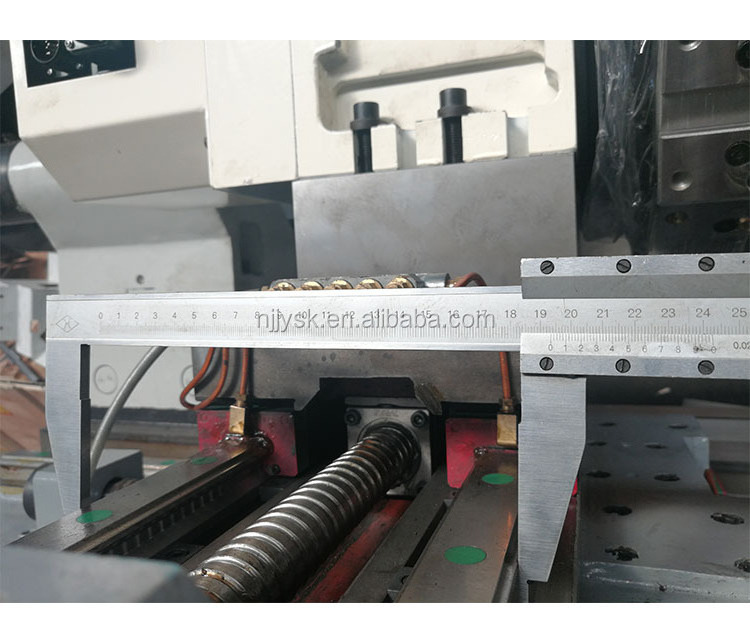

5 .TAIWAN HIWIN X/Z axis' linear rail for CKX500L CNC lathe

6.spindle bore diameter is 82mm,spindle nose diameter is 88mm for CKX500L CNC lathe

7.The Bed width is 610mm of CKX500L CNC lathe

8.the carrige width is 230mm of CKX500L CNC lathe

9.High precision Siemens unit for CNC turning center CKX500L

More details,please feel free contact with me

Heavy Duty CKX500L CNC Lathe Machine packages:

1. Inn

er package: Plastic spraying, antirust grease and Stretch film

2. Outside package: standard export wooden cases

1.Excellent guarantee and after-sale-service

a. User-friendly English software and detailed videos/CD

b. Free operator training

c. Free maintenance within 1 year for whole machine except of cnc system which guarantee is 3 years

d. 24-hours technical support by Email or Telephone

2. High quality

The main parts of our machines are imported from Japan,Germany and USA. Some are made in Taiwan.

You are welcomed to visit our factory.

3. Low Price

We make sure that for same price, our quality is much more excellent.

4.Customized or special design are OK