- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.03Mpa

-

Voltage:

-

AC220V

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

1000*600*1680mm

-

Weight:

-

150KG

-

Product name:

-

3 in 1 Semi-Automatic Aerosol Filling Machine

-

Function:

-

Aerosol Filling

-

Production capacity:

-

3000-5000cans/shift(8 hours)

-

Applicable can diameter:

-

20-750ml(can be choose)

-

Feature:

-

High Efficiency

-

Usage:

-

Daily Chemical

-

Advantage:

-

Efficiency

-

Material:

-

Stainless Steel

-

Working Pressure::

-

0.65-1.0Mpa

-

Machine type:

-

Semi-automatic High-speed

-

Certification:

-

ISO CE

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH

-

Packaging Material:

-

Metal

-

Filling Material:

-

Water, Oil

-

Filling Accuracy:

-

±0.03Mpa

-

Voltage:

-

AC220V

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

1000*600*1680mm

-

Weight:

-

150KG

-

Product name:

-

3 in 1 Semi-Automatic Aerosol Filling Machine

-

Function:

-

Aerosol Filling

-

Production capacity:

-

3000-5000cans/shift(8 hours)

-

Applicable can diameter:

-

20-750ml(can be choose)

-

Feature:

-

High Efficiency

-

Usage:

-

Daily Chemical

-

Advantage:

-

Efficiency

-

Material:

-

Stainless Steel

-

Working Pressure::

-

0.65-1.0Mpa

-

Machine type:

-

Semi-automatic High-speed

-

Certification:

-

ISO CE

Product Description

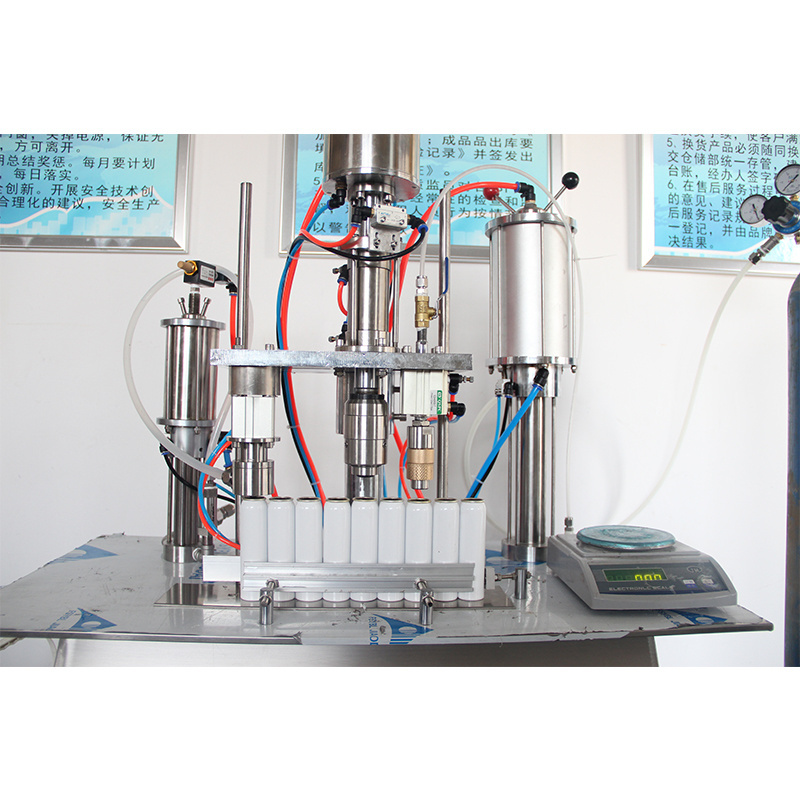

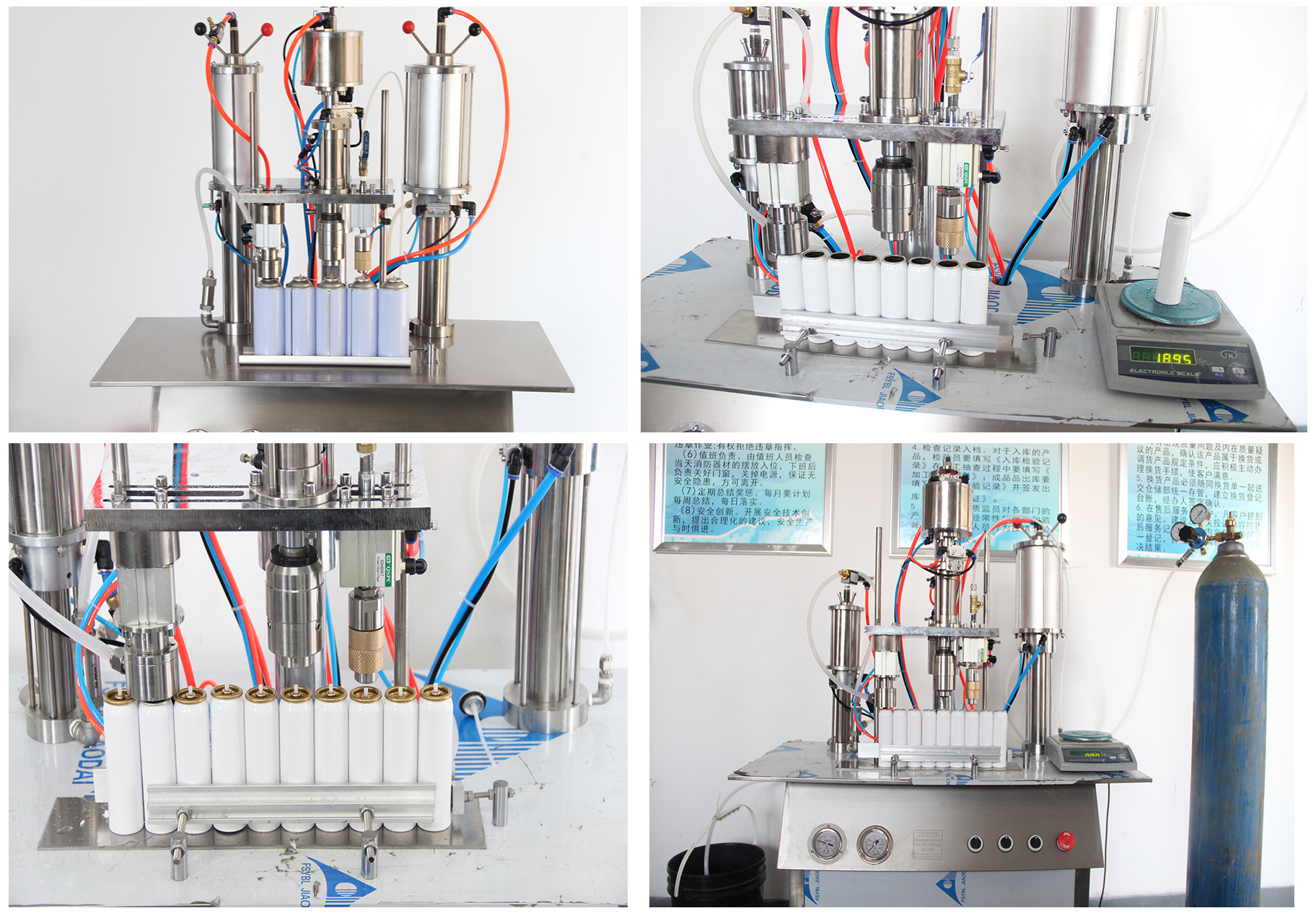

CJXH-1600A 3 in 1 Semi-Automatic Aerosol Filling Machine(manually push cans)

1.Liquid filling, sealing machine and gas filling machine including booster pump, operator can complete liquid Filling, sealing and gas filling on one worktable, single operation, save two labor Cost, and the filling speed and the labor intensity are same and other similar machines.

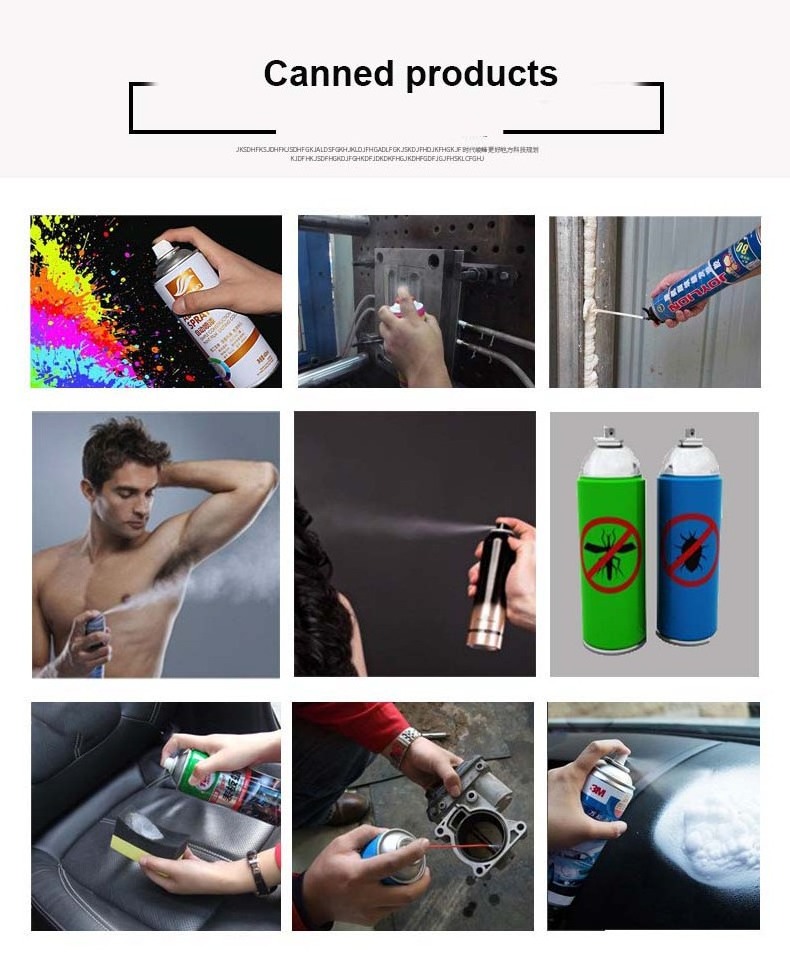

2.The machine is applied to fill various aerosol products; it is applied to batch produce in medium scale in aerosol filling factory.

3.The machine is widely used in cosmetic, fire protection, auto, chemical, foodstuff, Pharmacy etc industries, such as fixture, mousse, pesticide, freshener, detergent, Extinguishing agent, petroleum gas, DME and spray paint etc.

Details Images

The liquid filling machine adopts pumping type filling, the barrel of raw material doesn’t Need a high plane, filling and cleaning are all very easy, the feed-in mouth of Measurement cylinder adopts mandatory seal by check valve; ensure the sealing is safe and reliable. There is a liquid filter at the end of feed-in tube, prevent impurity into the cans.The sealing machine adopts mechanical motion control, simple air channel, rational Structure, adjustment is convenient, the sealing head is made of high quality stainless Steel, anti-fatigue, resistant to shock, sealing quality is reliable.

Manufacturing Technique

|

Production capacity:

|

3000-5000cans/shift(8 hours)

|

|

Max liquid volume(ml):

|

20-750ml(can be choose)

|

|

Max Gas volume(ml):

|

20-500ml(can be choose)

|

|

Sealing accuracy

|

≤±1%

|

|

Working Pressure:

|

0.65-1.0Mpa

|

|

Maximum air consumption:

|

0.9(m3/min)

|

|

Applicable aerosol can diameter:

|

35-65 (mm)

|

|

Applicable aerosol can height:

|

80-350(mm)

|

|

Packing size

|

1000*600*1680mm 150kg 560*320*820mm 35kg

|

|

Available valve:

|

1”(25.4mm)

|

Product Applications

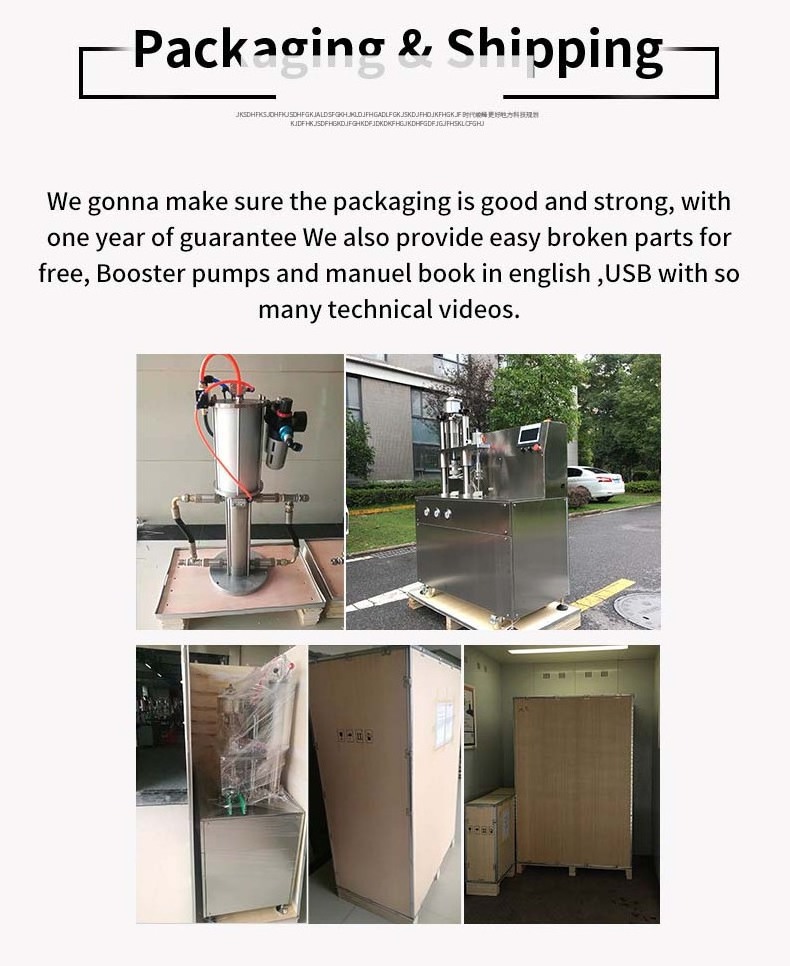

Product packaging

Production process

Hot Searches