- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Horizontal Directional Drilling Rig

-

Power rating:

-

113/2200kW/r/min

-

Max pull/thrust force:

-

225kN

-

Max pull/thrust speeed:

-

32m/min

-

Max spindle speed:

-

160r/min

-

Max fiow rate:

-

250L/min

-

Max pressure:

-

8MPa

-

Max inclination angle:

-

22 degree

-

Diamension(L*W*H):

-

5900*2250*2450mm

Quick Details

-

Weight (KG):

-

8500

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

SINOMADA

-

Product name:

-

Horizontal Directional Drilling Rig

-

Power rating:

-

113/2200kW/r/min

-

Max pull/thrust force:

-

225kN

-

Max pull/thrust speeed:

-

32m/min

-

Max spindle speed:

-

160r/min

-

Max fiow rate:

-

250L/min

-

Max pressure:

-

8MPa

-

Max inclination angle:

-

22 degree

-

Diamension(L*W*H):

-

5900*2250*2450mm

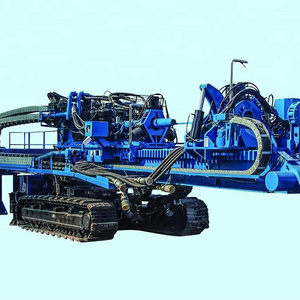

Sale HDD Horizontal Directional Dril Rig Mini Horizontal Directional Drilling Machine Used In Electric Supply

|

Description |

Unit |

Parameter value |

||

|

Engine |

Manufacturers |

|

Imported Engine |

|

|

China III |

Model |

|

QSB5.9-C150 |

|

|

Rated Power |

kW /(r/min) |

113 / 2200 |

||

|

China II |

Model |

|

6BTAA5.9-C150 |

|

|

Rated Power |

kW /(r/min) |

112/ 2200 |

||

|

China III |

Model |

|

QSB4.5-C160 |

|

|

|

||||

|

EU Stage IIIA |

Rated Power |

kW /(r/min) |

119/2200 |

|

|

Thrust-Pull |

Type |

|

Pinion and rack drive |

|

|

Max thrust-pull force |

kN |

225/225 |

||

|

Max thrust-pull speed |

m/min |

26 |

||

|

Rotation |

Type |

|

two motor |

|

|

Torque |

N·m |

6350 |

||

|

Max spindle speed |

r/min |

160 |

||

|

Loader Crance |

/ |

/ |

||

|

Max inclination angle |

° |

22 |

||

|

Pipe |

Diameter × Length |

mm×mm |

Φ60×3000 |

|

|

Mud pump |

Max Flow rate |

L/min |

250 |

|

|

Max pressure |

MPa |

8 |

||

|

Weight |

kg |

8500 |

||

Features:

1, Hydraulic pilot control, with comfortable handling and flexible regulation, first-class brand of hydraulic components to ensure the reliability of the whole hydraulic system.

2, Rack and pinion sliding, to ensure the stability of the carriage and the reliability of drive operational. Carriage floating, floating vise patented technology can greatly protect the drill pipe thread, increase the service life of the drill pipe.

3, High-speed sliding systems, variable motor to achieve high and low carriage sliding change, increasing the ability to adapt the drilling rig working conditions, improve the efficiency of the drilling rig construction.

4, Stable chassis support, using the classic H-beam structure, high quality rubber track, breaststroke leg structure, provide a strong guarantee for the stability of the whole construction.

5, Support the diverse needs of customers, the machine can be increased with the automatic (semi-automatic) drill pipe handling device, automatic anchoring system, cab, air conditioning wind, freezing mud, mud washing and other devices, can also optional more environmentally friendly.

It's applicable for pipeline construction about Municipal Construction (Electric,Communication,Water Supply) and Natural Gas,Oil Delivery.