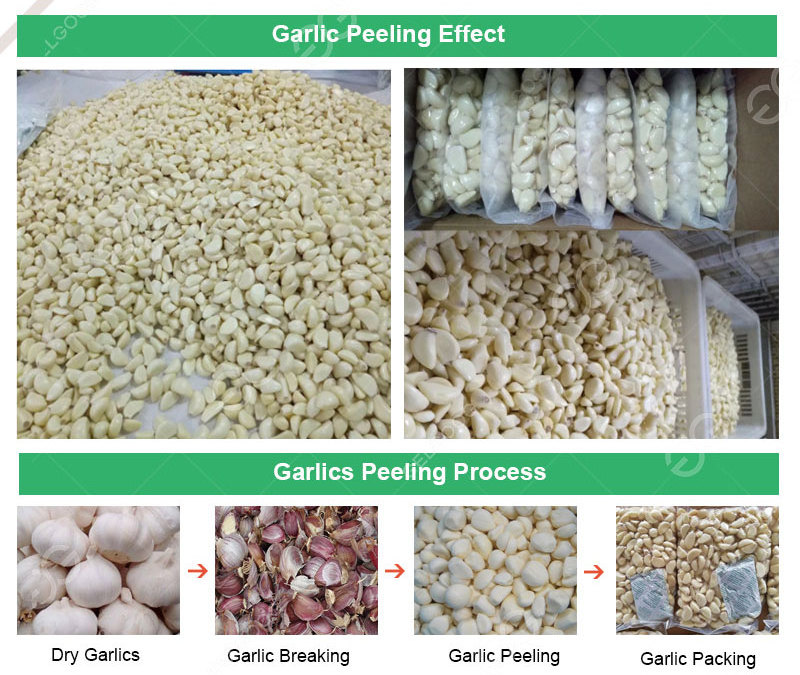

Garlic--Root Cutting--Grading--elevating--garlic bulb separating--picking--elevating--garlic

peeling--Washing--Cooling--Slicing--Dehydrating--Grinding--final product picking--packing

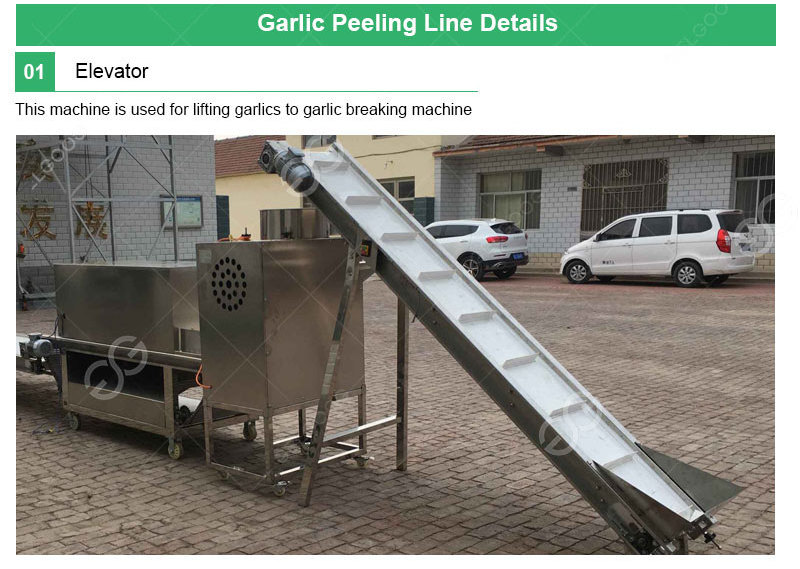

1. Elevator: the elevator is used to send the garlic into the separating machine and peeling machine evenly.

2. Garlic bulbs separating machine: separating the garlic bulbs into garlic cloves which can be used to peel. Stripping rate can reach 98%.

3. Garlic peeling machine: using air automatic peeling, automatic separation of skin and garlic cloves, peeling clean and damage-free.

4. Picking line: pick the unqualified garlic by manual picking to improve the garlic quality.

About the price of this garlic powder making machine. it depends on the capacity and your other special requirement.