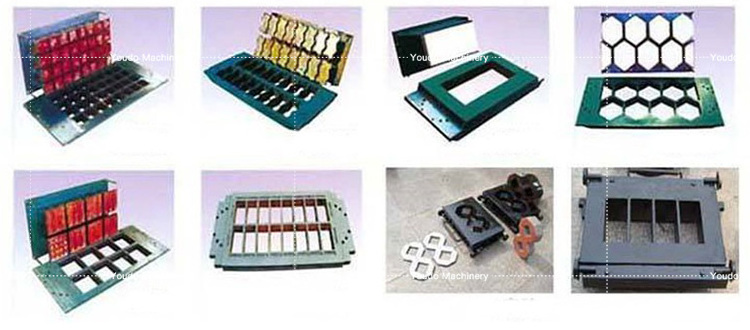

You can customize the shape and size of bricks according to customer needs. For more details, please consult customer service

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UD

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

1150*1370*1650mm

-

Weight (KG):

-

650 kg

-

Model:

-

UDZZ-35A

-

Forming cycle:

-

30s-40s

-

Capacity:

-

2~4 pcs/time

-

Reducer:

-

30:1

-

Total Power:

-

4.8KW

-

Weight:

-

650KG

-

Size:

-

1150*1370*1650mm

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Clay,cement,concrete,etc

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UD

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

1150*1370*1650mm

-

Weight (KG):

-

650 kg

-

Model:

-

UDZZ-35A

-

Forming cycle:

-

30s-40s

-

Capacity:

-

2~4 pcs/time

-

Reducer:

-

30:1

-

Total Power:

-

4.8KW

-

Weight:

-

650KG

-

Size:

-

1150*1370*1650mm

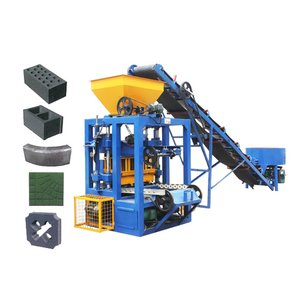

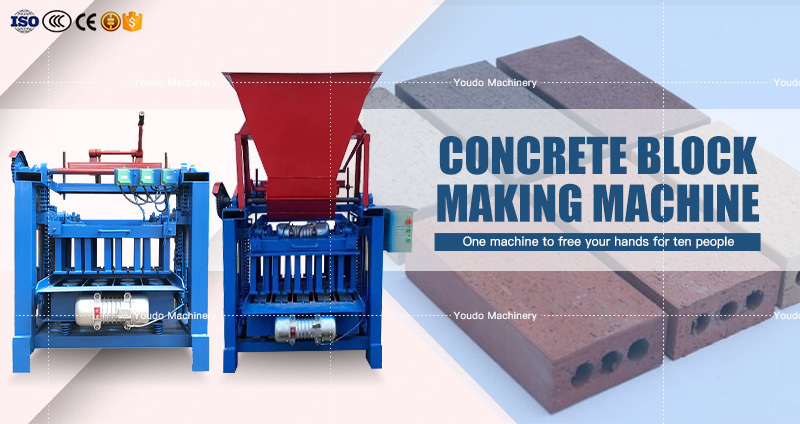

UDZZ-35A

UDZZ-35A With Hopper

Hollow Block Making Machine Price Concrete Block Machine

The UDZZ-35A brick machine is easy to operate, easy to maintain, flexible to change molds, and less investment.

Quickly produced blocks have high strength, can stand on demoulding, and can be stacked in a short time, which can save 5-10% of cement. Appearance The size and edges are regular, making it the ideal model.

The small block brick machine can produce color pavement bricks, lawn bricks, small concrete hollow blocks, porous bricks, curb stones, wall blocks, etc. by changing the mold.

The product quality is excellent, the production efficiency is high, the products have the characteristics of beautiful appearance, diverse patterns, convenient construction, short construction period and low investment.

The machine is small in size and simple in operation. It is a new model with low investment and high profit. The paved road surface has good water permeability, is simple to lay and easy to update.

|

Model

|

UDZZ-

35A

|

|

|

Forming cycle

|

30s-40s

|

|

|

Capacity

|

2~4 pcs/time

|

|

|

Reducer

|

30:1

|

|

|

Total Power

|

4.8KW

|

|

|

Weight

|

650KG

|

|

|

Package size

|

1150*1370*1650mm

|

|

|

400*200*200mm 4pcs/time 390*190*190mm 4pcs/time

390*150*190mm 5pcs/time 390*140*190mm 5pcs/time

390*120*190mm 6pcs/time 240*115*53mm 26pcs/time

KINDS SIZES,CAN CUSTOMIZE AS YOUR NEEDS.

|

|

|

Finished product display

Various external wall blocks, internal wall blocks, flower wall blocks, floor slab blocks, embankment blocks, interlocking pavement blocks and curbstone blocks can also be produced.

Product advantages

Customized mold

Applicable raw materials:

Using sand, stones, cement, a large number of industrial wastes such as fly ash, slag, steel slag, coal gangue, ceramsite, and perlite can be added in large quantities.

Using sand, stones, cement, a large number of industrial wastes such as fly ash, slag, steel slag, coal gangue, ceramsite, and perlite can be added in large quantities.

Future of block brick making machine:

1.

Strong stability and abrasion resistance.

2. Install the travel switch, which greatly improves the product quality, has the characteristics of high pressure, good performance and easy operation.

3. The manual mud brick machine has

the advantages of simple structure, compactness, convenient operation, convenient maintenance, small hardness, high output, less investment and quick effect.

4. The raw materials are abundant and can be seen everywhere. It is very convenient to invest and build factories.

5. Fast product forming, high density and high pressure.

Product detail

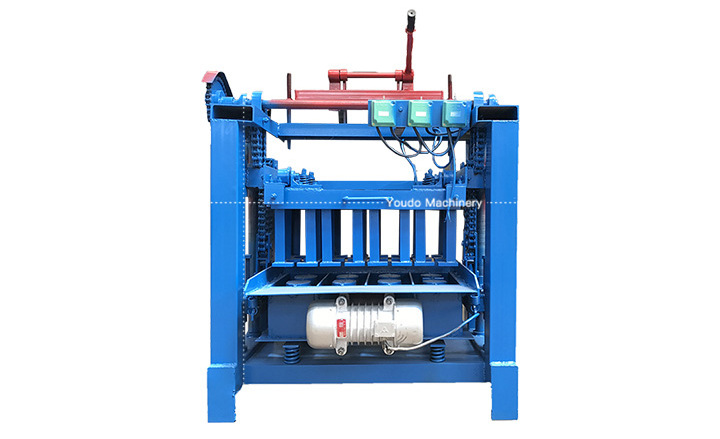

The cement brick making machine

adopts four-column orientation and is equipped with a strong vibration motor. It uses a vibration table to directional vertical vibration and upper mold pressurization vibration.

With less power, it achieves a strong vibration effect and makes each raw material.

It can effectively flow and fill densely, which greatly improves production

The machine

adopts upper die push and pull, manual scraping, and brick output. The operation is convenient and flexible, and you can quickly become familiar with it.

The wooden pallet will not be impacted by the synchronous resonance with the mold during forming, and the service life of the wooden pallet will be more than double that of similar products.

One machine with multiple functions, equipped with different specifications of molds, can produce different specifications of cement bricks, and the molds are easy to replace and maintain.

The pressure head can move longitudinally, which is convenient for feeding, maintenance and washing. The gap between the pressure foot and the mold box is small, the block burrs are small, and the appearance is good.

Product real photo

After Sales Service

Quality assurance

We have always focused on research and development because they are the key to our corporate innovation. They make us do better in production, technical service and marketing.

We provide high-quality machines and professional after-sales service.

Our goal is to maximize customer satisfaction and value. We usually provide 1 year warranty and free common accessories.

assured.When disassembling, we will paste the corresponding label on each part, and provide multi-language installation video and instruction manual. Customer satisfaction is our aim.

We provide high-quality machines and professional after-sales service.

Our goal is to maximize customer satisfaction and value. We usually provide 1 year warranty and free common accessories.

We promise that our products are brand new and have not been used. They are made of corresponding materials and adopted a new design.

The quality, specifications, and functions are in compliance with the contract requirements.

We promise that the products produced on this production line can be stored for one year without any additives.

The quality, specifications, and functions are in compliance with the contract requirements.

We promise that the products produced on this production line can be stored for one year without any additives.

Test and teardown

We will take the initiative to test the operation of the machine when it is completed, and take videos to let customers rest

assured.When disassembling, we will paste the corresponding label on each part, and provide multi-language installation video and instruction manual. Customer satisfaction is our aim.

Package

We will wrap the machine with film to avoid damp and scattered during transportation, and thicken the export wooden box to surround the machine to protect the machine from impact and friction. The size depends on the machine.

Transportation

We can provide multiple channels of transportation. We guarantee that the freight forwarders we use have more than 5 years of cooperation history, provide you with fast timeliness and economic prices, and ensure the safety and integrity of your machines.

Installation and commissioning

After the equipment arrives at the customer's workshop, please arrange the equipment in accordance with the floor plan drawn up by us. During the epidemic, we can use online videos or video tutorials to guide debugging.

After the epidemic is over, we can also arrange professional engineers to your factory. You need to provide our engineers' round-trip air tickets and accommodation, as well as salary.

company information

Youdo machinery

is a factory with 10 years experience in machinery production and foreign trade.

In the past ten years, we have helped friends from 152 countries to start their businesses. With our support, 1,230 friends have made their business bigger and bigger and ranked among the forefront of the industry.

We have received after-sales praise from more than 10,000 friends, we strictly control the quality of our products, and have

long-term cooperation with 127 large foreign companies based on the principle of mutual benefit.

In the past ten years, we have helped friends from 152 countries to start their businesses. With our support, 1,230 friends have made their business bigger and bigger and ranked among the forefront of the industry.

We have received after-sales praise from more than 10,000 friends, we strictly control the quality of our products, and have

long-term cooperation with 127 large foreign companies based on the principle of mutual benefit.

Our service tenet is:

Choosing us makes you rich.

Finding us means that you will find a one-stop solution to your needs.

Choose us to start your business development journey, please let me grow with you, my friend.

Finding us means that you will find a one-stop solution to your needs.

Choose us to start your business development journey, please let me grow with you, my friend.

Certificate display

Packing & Delivery

Why Choose Us

FAQ

Question1:

Are you manufacturer?

A: Yes, we are manufacturer with more than 10 years' experience.

A: Yes, we are manufacturer with more than 10 years' experience.

Question2:

What are your advantages compared with your competitors?

A:

With rich industry experience and strict Product Quality Control systems, we provide:

1. Stable and reliable product at reasonable price

2. Good customer service: Fast response to any inquiry or question

3. On-time delivery.

Question 3:

What's the delivery time and w

hich ports do you usually ship at

?

A

:

We will deliver the product in 7 days after receiving the deposit.

We can load container at: Qingdao, Shanghai, Tianjin, Guangzhou etc.

Question4

:

What's the lifetime of the wearing parts?

A:

The material of our product is of high quality, and the lifetime of our wearing parts is twice longer than the others,including the roller skin, die and bearing.

Question5

:

What

shall we do if breakdown occurs?

A:

.

In case of failure, please inform us. During the warranty period, in case of failure, we will respond in time after receiving the buyer's notice. We will handle the fault by telephone / fax or email according to the buyer's requirements.

Question 6:

Do you have English Manual for each machinery?

A:

Yes. The instruction manual,the test report and other Data Sheets related shall be provided by us.

Question7

:

Do you have some foreign customers useing your equipments?

A:

Yes , we have customers all over the world.

Question8

:

MOQ(Minimum Order Quantity)

A:

One set is welcome, and mix products for order are welcome.

Question 9:

Can you customize the machine for me ?

A: Yes, we can customize according to customer's requirements.

A: Yes, we can customize according to customer's requirements.

Question10

:

Package

A:

Standard export wooden case or other packages depending on products packaging weight is subject to the actual pack.

Question11:

How long is your warranty?

A:

The warranty period of our products is one year (excluding man-made damage and misuse). During the warranty period, we will provide maintenance videos or face-to-face videos to teach you. If the machine has serious quality problems, we support returning it.

Question 12:

What are your Payment Terms?

A: Payment shall be made by T/T, L/C, or D/P, etc., it varies considerably according to the region that you are in.

A: Payment shall be made by T/T, L/C, or D/P, etc., it varies considerably according to the region that you are in.

Question 13:

Can you show how the machine works?

A:

Certainly, we will send you the Operating video & instruction to you together with machines, to help you use the machines better.

Question 14:

Do you have any other fish processing equipment?

A: Yes. we have fish pre processing equipment and deep process machinery, such as fish head removing machine, fish block making

machine, fish scaling machine, fish gutting machine, fish bone and meat separating machine, fish ball making machine.etc.

A: Yes. we have fish pre processing equipment and deep process machinery, such as fish head removing machine, fish block making

machine, fish scaling machine, fish gutting machine, fish bone and meat separating machine, fish ball making machine.etc.

Hot Searches