- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

based on the model

-

Weight:

-

20000 KG

-

Name:

-

raymond mill

-

Installation:

-

Engineer Guide

-

Material:

-

Carbon Steel

-

Processed Materials:

-

Minerals

-

The Machines classification:

-

Mining Equipment

-

Price:

-

Negotiatable

-

Quality:

-

Advanced Technology

-

Function:

-

Milling Material

-

Factory visit:

-

Welcomed Warmly

-

Color:

-

Customizable

Quick Details

-

Capacity(t/h):

-

100 Set/Sets per Month

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Eastman

-

Dimension(L*W*H):

-

based on the model

-

Weight:

-

20000 KG

-

Name:

-

raymond mill

-

Installation:

-

Engineer Guide

-

Material:

-

Carbon Steel

-

Processed Materials:

-

Minerals

-

The Machines classification:

-

Mining Equipment

-

Price:

-

Negotiatable

-

Quality:

-

Advanced Technology

-

Function:

-

Milling Material

-

Factory visit:

-

Welcomed Warmly

-

Color:

-

Customizable

Product Description

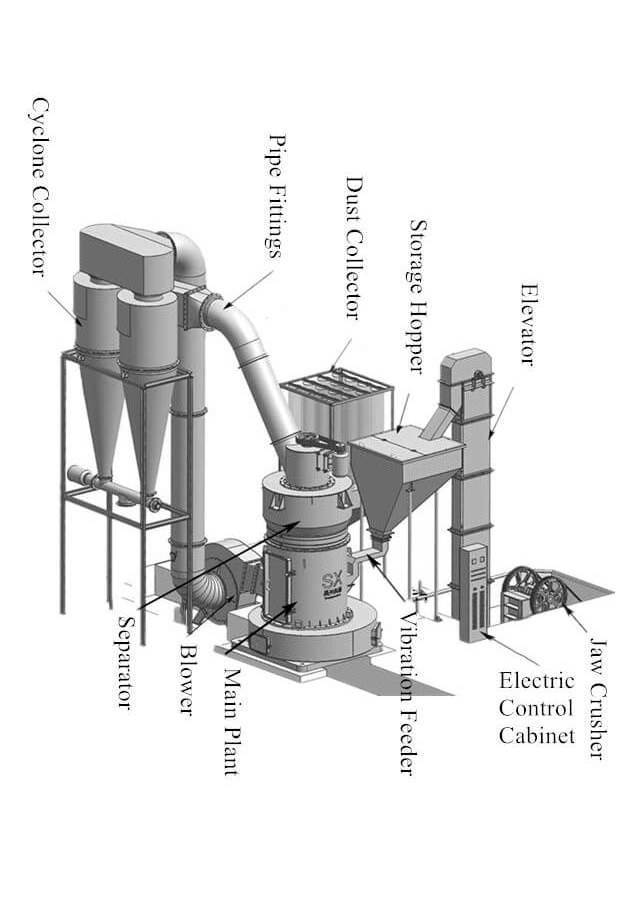

Raymond Mill Working Principle

The working process of the whole mill: After the bulk material is crushed to the required particle size by the jaw crusher, the material is sent to the storage hopper by elevator, and then the material is continuously fed in evenly and quantitatively through the vibrating feeder Grinding in the main machine grinding chamber, the ground powder is taken away by the airflow of the fan, and

classified by the analyzer. The fineness of the powder enters the large cyclone collector through the pipe with the airflow for separation and collection, and then the powder is discharged The valve discharge is the finished powder. The airflow is sucked into the blower by the return duct at the upper end of the large cyclone collector. The entire airflow system of this machine is closed and circulating, and it circulates under the condition of positive and negative pressure.

classified by the analyzer. The fineness of the powder enters the large cyclone collector through the pipe with the airflow for separation and collection, and then the powder is discharged The valve discharge is the finished powder. The airflow is sucked into the blower by the return duct at the upper end of the large cyclone collector. The entire airflow system of this machine is closed and circulating, and it circulates under the condition of positive and negative pressure.

【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher>, electric control cabinet, feeder, main plant, blower, separator, etc.,

Structural Features

1. The whole mill is of spatial structure, less premise and systemic strong. The whole system from roughing, transportation,powder collecting to packaging forms an independent production system.

2. Even granularity, sieving rate 99%, which is unapproachable for other mills.

3. The driving device applies an enclosed gearbox and belt pulley, so the transmission is calm and the operation is reliable.

4. All the main parts of Raymond Mill adopt high-quality steel, the resistant parts use high performance proof materials, so the whole system has high wear resistance and reliable performance. The blade frame of the main machine keeps in touch with the materials, it consists of the upper part and lower part, when the lower part is worn down, just take down the bolts to exchange it.

5. Centralized controlling of the electrical system, unmanned operation, easy maintenance.

6. Less dust pollution, low noise.

7. Adopting an electro-vibrating feeder, it can feed evenly and is easy to adjust, features miniature size, lightweight, power-saving, and easy maintenance.

Structural Features

1. The whole mill is of spatial structure, less premise and systemic strong. The whole system from roughing, transportation,powder collecting to packaging forms an independent production system.

2. Even granularity, sieving rate 99%, which is unapproachable for other mills.

3. The driving device applies an enclosed gearbox and belt pulley, so the transmission is calm and the operation is reliable.

4. All the main parts of Raymond Mill adopt high-quality steel, the resistant parts use high performance proof materials, so the whole system has high wear resistance and reliable performance. The blade frame of the main machine keeps in touch with the materials, it consists of the upper part and lower part, when the lower part is worn down, just take down the bolts to exchange it.

5. Centralized controlling of the electrical system, unmanned operation, easy maintenance.

6. Less dust pollution, low noise.

7. Adopting an electro-vibrating feeder, it can feed evenly and is easy to adjust, features miniature size, lightweight, power-saving, and easy maintenance.

Features

1. Mineral materials with Mohs hardness less than 9.3 can be processed and crushed.

2. The finished product has a wide range of particle sizes, the coarsest particle size can reach 0.95 mm (20 mesh), the fine powder particle size can generally reach 0.038 mm (400 mesh), and the finest part of the material can reach 0.013 mm (1000 mesh).

3. The dust removal effect fully meets the national dust emission standard.

4. The analysis machine is easy to adjust.

5. The grinding device adopts overlapping multi-stage sealing with good sealing performance.

1. Mineral materials with Mohs hardness less than 9.3 can be processed and crushed.

2. The finished product has a wide range of particle sizes, the coarsest particle size can reach 0.95 mm (20 mesh), the fine powder particle size can generally reach 0.038 mm (400 mesh), and the finest part of the material can reach 0.013 mm (1000 mesh).

3. The dust removal effect fully meets the national dust emission standard.

4. The analysis machine is easy to adjust.

5. The grinding device adopts overlapping multi-stage sealing with good sealing performance.

Product Paramenters

|

Model

|

Grind roller

|

|

|

Grinding ring

|

|

Feed size

(mm) |

|||

|

|

Q'ty

|

Dia.

(mm) |

Height

(mm) |

Outer Dia.

(mm) |

Height

(mm) |

|

|||

|

3R1410

|

3

|

140

|

100

|

495

|

100

|

<8

|

|||

|

3R2115

|

3

|

210

|

150

|

726

|

150

|

<15

|

|||

|

3R2615

|

3

|

260

|

150

|

865

|

150

|

<15

|

|||

|

3R2715

|

3

|

270

|

150

|

884

|

150

|

<15

|

|||

|

3R3015

|

3

|

300

|

150

|

965

|

150

|

<15

|

|||

|

4R3016

|

4

|

300

|

160

|

990

|

160

|

<20

|

|||

|

4R3216

|

4

|

320

|

160

|

1073

|

160

|

<25

|

|||

|

5R4119

|

5

|

410

|

190

|

1400

|

190

|

<30

|

|||

Successful Cases

Packaging&Dilvery

|

1.Standard Parts Packed in the Wooden Cases

|

|

2.Big Parts Packed by Plastic Membrane

|

|

3.The Whole Machine is Loaded in the Container .

|

Company Introduction

Ganzhou Eastman Technology Co, Ltd

.

is a privatization enterprise, which focuses on mining equipment R&D,manufacturing and sales, the main products include sand and stone making equipment ,new type dry technology cement producing equipment,limestone producing equipment etc.

Besides, we also design and install sand project and some ecological improvement equipment, and self-operate and agent import and export business for all kinds of products.The stone and sand making production process, mineral separation system, grinding system and drying system which independently R&D by our company have been the world leading level.

Our factory has an area of 10000 square meters, USD 1000 million fixed assets.

Our engineer and technical personnel covering 15% of the total staff.

Customers come to visit our factory

At the same time, our products are also exported to more than 30 countries,Here are some of our customers come to visit our factory for your reference.

FAQ

why do we choose you over others ?

1. experience : Founded in 1985, we have nearly 40 years of production experience. we have more experiences in this which would save your precious time and money .

2.With our profound accumulations in design ,manufacturing and marketing ,quality can be assured .

3.Strict self inspection ,you will always be happy working with us because we make less mistakes than others .

do you accept inspections ?

Yes ,you're always welcomed to come .Every year we have lots of customers coming to our workshop ,please do not hesitate to contact us for inspections .

how can I choose the correct Model ?

With following info we can tell everything: What is the targeted Raw material ?

Granite/gobble/basalt/limestone/quartzite/diabase/iron core/gold ore/copper ore ? maximal size of the raw material ?give us a range . what is the discharging size ? etc...

Granite/gobble/basalt/limestone/quartzite/diabase/iron core/gold ore/copper ore ? maximal size of the raw material ?give us a range . what is the discharging size ? etc...

Please note this :the more specific information you provide ,more more we can do for you and the better price we can offer you .

How long is the gaurantee ?

All of our products are guaranteed for one year. If products quality is not consistent with the description as we described , we promise 100% refund.

Hot Searches