- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dawn

-

Product name:

-

Thermoplastic elastomers

-

Color:

-

Natural

Quick Details

-

color:

-

white

-

Shape:

-

granuls

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dawn

-

Product name:

-

Thermoplastic elastomers

-

Color:

-

Natural

Product Description

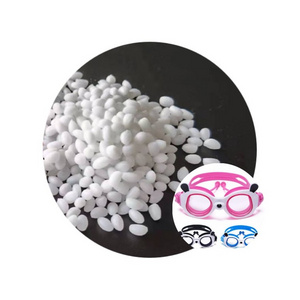

Dawn thermoplastic elastomers tpe plastic raw material

DAWN TPE adhesive series can be used for injection and other molding methods; material processing performanceis good,the product appearance is exquisite, feel good. High and low temperature resistance and aging resistance

Specification

|

ProductCategory

|

Grade

|

Test Criteria, Test Items

|

Test Criteria, Test Items

|

|

|

|

|

|

Property and Application

|

|||||

|

|

|

Shore A

|

Density

g/cm³ |

Tensile Strength Mpa

|

Elongation at Break %

|

100%Stretching Strength

Mpa |

300%Stretching Strength

Mpa |

Tear Stength KN/m

|

Property and Application

|

|||||

|

|

|

ASTM D2240

|

ASTM 792

|

ASTM 412

|

ASTM 412

|

ASTM 412

|

ASTM 412

|

ASTM 624

|

|

|||||

|

extrusion stage

|

3012-PB

|

28

|

0.94

|

4.9

|

650.0

|

0.5

|

1.3

|

19.4

|

Sealing Strip

|

|||||

|

|

3611-PB

|

35

|

0.88

|

5.6

|

860.0

|

0.6

|

1.8

|

28.0

|

Sealing Strip

|

|||||

|

|

3612-PB

|

33

|

0.94

|

5.6

|

860.0

|

0.5

|

1.6

|

27.0

|

Sealing Strip

|

|||||

|

|

4511-PB

|

45

|

1.04

|

5.3

|

569.0

|

1.1

|

2.7

|

25.0

|

Sealing Strip

|

|||||

|

|

4612-PB

|

48

|

0.98

|

6.8

|

775.0

|

1.1

|

1.9

|

29.2

|

Sealing Strip

|

|||||

|

|

5512-PB

|

55

|

0.95

|

6.5

|

646.9

|

1.2

|

2.3

|

23.6

|

Sealing Strip

|

|||||

|

|

5511-PB

|

51

|

1.05

|

8.8

|

707.0

|

1.3

|

2.3

|

36.3

|

Sealing Strip

|

|||||

|

|

6512-PB

|

65

|

0.97

|

12.1

|

761.0

|

1.8

|

3.0

|

43.0

|

Sealing Strip

|

|||||

|

|

6511-PB

|

65

|

1.05

|

9.6

|

602.5

|

2.2

|

4.8

|

43.0

|

Sealing Strip

|

|||||

|

|

6511-PC

|

68

|

1.12

|

9.9

|

790.0

|

1.9

|

3.0

|

36.9

|

Sealing Strip

|

|||||

|

|

6912-PB

|

70

|

0.99

|

14.2

|

730.0

|

2.1

|

3.7

|

48.0

|

Sealing Strip

|

|||||

|

|

7011-PB

|

70

|

0.99

|

15.5

|

776.6

|

2.9

|

4.2

|

40.2

|

Sealing Strip

|

|||||

|

|

7011-PC

|

70

|

1.10

|

11.7

|

740.0

|

2.2

|

3.4

|

39.7

|

Sealing Strip

|

|||||

|

|

8511-PB

|

82

|

1.00

|

17.3

|

700.2

|

3.7

|

5.2

|

52.0

|

Sealing Strip

|

|||||

|

|

8811-PB

|

88

|

1.00

|

20.4

|

788.2

|

4.9

|

6.3

|

63.3

|

Sealing Strip

|

|||||

|

|

8911-PB

|

91

|

1.00

|

23.0

|

708.0

|

5.4

|

7.2

|

80.0

|

Sealing Strip

|

|||||

|

|

9011-PB

|

95

|

0.98

|

24.0

|

811.3

|

7.5

|

8.4

|

88.7

|

Sealing Strip

|

|||||

|

|

9611-PC

|

95

|

1.06

|

22.2

|

820.0

|

7.7

|

8.6

|

88.9

|

Sealing Strip

|

|||||

|

|

5012D-PB

|

52D

|

0.96

|

29.8

|

826.0

|

12.1

|

11.7

|

159.0

|

Sealing Strip

|

|||||

|

|

6012D-PB

|

62D

|

1.02

|

20.4

|

108.0

|

14.8

|

14.8

|

104.0

|

Sealing Strip

|

|||||

|

automotive injection molding grade

|

4001-PA

|

40

|

1.10

|

6.0

|

650.0

|

0.8

|

1.5

|

22.0

|

Car air conditioner damper

|

|||||

|

|

4002-PA

|

40

|

1.10

|

6.0

|

650.0

|

0.8

|

1.5

|

22.0

|

Car air conditioner damper

|

|||||

|

|

6301-PB

|

60

|

0.98

|

6.5

|

650.0

|

1.3

|

2.5

|

23.0

|

Triangle window

|

|||||

|

|

6501-PB

|

65

|

0.98

|

5.5

|

750.0

|

1.3

|

2.5

|

30.0

|

Auto interior gasket

|

|||||

|

|

6801-PB

|

68

|

0.99

|

6.8

|

750.0

|

1.6

|

3.8

|

30.0

|

Auto interior gasket

|

|||||

|

|

7501-PB

|

75

|

1.00

|

7.5

|

800.0

|

2.5

|

3.8

|

37.5

|

Auto interior gasket

|

|||||

|

|

8001-PB

|

80

|

0.96

|

10.0

|

750.0

|

3.1

|

4.4

|

50.0

|

Auto interior gasket

|

|||||

|

|

8801-PB

|

90

|

0.96

|

8.8

|

500.0

|

4.4

|

5.6

|

50.0

|

Auto interior gasket

|

|||||

|

|

9301-PB

|

95

|

0.98

|

15.0

|

625.0

|

5.0

|

6.3

|

75.0

|

Auto ventilation cover

|

|||||

|

|

4003-PB

|

40

|

0.90

|

6.3

|

800.0

|

0.6

|

1.5

|

25.0

|

Auto dust cover

|

|||||

|

|

4702-PB

|

43

|

0.89

|

8.0

|

800.0

|

0.8

|

1.8

|

25.0

|

Auto dust cover

|

|||||

|

|

5001-PC

|

50

|

1.06

|

5.0

|

800.0

|

0.6

|

1.5

|

20.0

|

Auto dust cover

|

|||||

|

|

6001-PC

|

60

|

1.09

|

5.0

|

750.0

|

0.6

|

1.5

|

20.0

|

Auto dust cover

|

|||||

|

|

3501-PB

|

35

|

0.98

|

5.5

|

800.0

|

0.6

|

1.3

|

25.0

|

Auto buffer block

|

|||||

|

|

5001-PB

|

50

|

1.00

|

3.8

|

750.0

|

1.5

|

2.0

|

25.0

|

Auto buffer block

|

|||||

|

|

6001-PB

|

60

|

0.96

|

5.5

|

800.0

|

1.8

|

2.8

|

37.0

|

Auto buffer block

|

|||||

|

|

7001-PB

|

70

|

1.03

|

15.0

|

800.0

|

1.8

|

3.1

|

45.0

|

Auto buffer block

|

|||||

1.high temperature resistance, there is no obvious change in appearance after long-term thermal aging at100°C *168h

2.Excellent acid and alkali resistance, strong chemical

resistance

3.The material has strong elasticity, and the tympanicmembrane effect is better. and the excellent anti-fatiqueproperty prolongs the service life of the plate

Product Applications

Hot Searches