- Product Details

- {{item.text}}

Quick Details

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

New Product 2021

-

Core Components:

-

Engine Motor Pump

-

Product name:

-

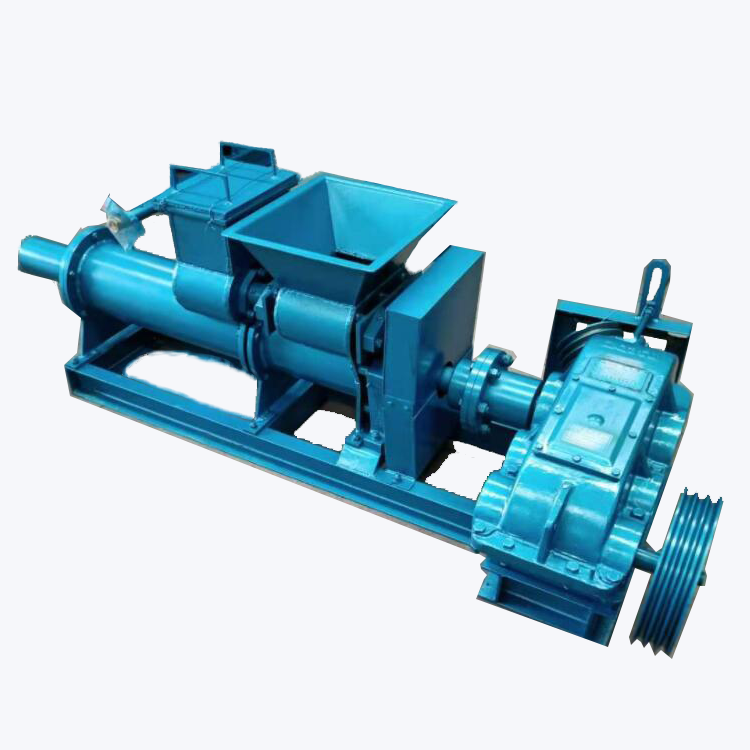

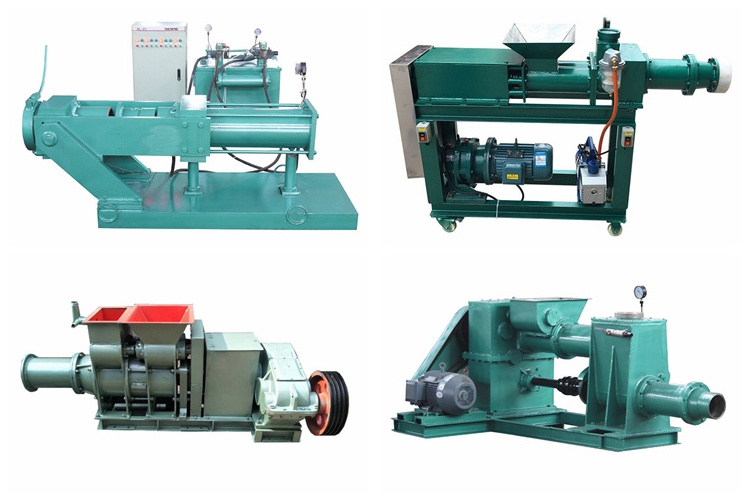

Vacuum Clay Machine for ceramic cargo making

-

Voltage:

-

220V and 380V

-

Color:

-

can be customized

-

Apply area:

-

Ceramic products factory

-

Configuration:

-

newly produced machine

-

MOQ:

-

1 set by LCL

-

Mould:

-

can be made

-

Debugging:

-

by video easily

-

Feature:

-

High Efficiency

Quick Details

-

Place of Origin:

-

Hebei China

-

Brand Name:

-

RUNYING

-

Weight (KG):

-

1

-

Video outgoing-inspection:

-

Provided

-

Machinery Test Report:

-

Provided

-

Marketing Type:

-

New Product 2021

-

Core Components:

-

Engine Motor Pump

-

Product name:

-

Vacuum Clay Machine for ceramic cargo making

-

Voltage:

-

220V and 380V

-

Color:

-

can be customized

-

Apply area:

-

Ceramic products factory

-

Configuration:

-

newly produced machine

-

MOQ:

-

1 set by LCL

-

Mould:

-

can be made

-

Debugging:

-

by video easily

-

Feature:

-

High Efficiency

Tangshan Runying Machinery Ltd, is a professional machinery solution provider, located in the famous international trade city of Tangshan ( nearby Tianjin port ). We have advanced equipment, rich experience, highly-qualified scientific researchers and professional staff members for the after-sales services. To meet different needs of customers, strive to improve product quality, sincerely serve the market and customers, and become a trusted friend of customers is the constant pursuit of us!

|

Type

|

TC-200

|

TC-250A

|

|

|

Production capacity

|

1500~2000 kg/h

|

4000~5000 kg/h

|

|

|

Power

|

11 kw

|

22 kw

|

|

|

Application

|

Vacuum clay mixing machine is the main professional machinery in the ceramic industry. It is mainly used for the preparation of clay for bricks and tiles, daily-use porcelain and industrial porcelain. Various molds are added to the front end of the clay outlet to extrude various ceramics. And various ceramic components such as tile. If used in an automatic production line for daily-use pottery molding, it can become an automatic quantitative feeding machine.

|

|

|

|

Remark

|

The mud mill is suitable for the water content of the mud to be prepared between 18.5 and 22%. For the mud with relatively high hard material, the water content of the mud should be lower, and for the mud with high soft material. , The moisture content of materials along the line can be higher.

|

|

|

Hot Searches