- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DTEC

-

Model Number:

-

DT210

-

After-sale Service:

-

24 Months

-

Measuring Range:

-

0.75~300mm (in Steel)

-

Precision:

-

0.1mm

-

Min. Testing Dia.:

-

Dia.25x3 mm

-

Gain Adjustable:

-

3 Level Gain Adjustable

-

Storage:

-

20 files (up to 99 values for each file)

-

Communication:

-

Mini-USB interface

-

Calibration Mode:

-

Zero-point, Two-point

-

Measurement Unit:

-

Metric/Imperial unit selectable

-

Power Supply:

-

Two "AA" size

Quick Details

-

Warranty:

-

1 year

-

Type:

-

LCD

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

DTEC

-

Model Number:

-

DT210

-

After-sale Service:

-

24 Months

-

Measuring Range:

-

0.75~300mm (in Steel)

-

Precision:

-

0.1mm

-

Min. Testing Dia.:

-

Dia.25x3 mm

-

Gain Adjustable:

-

3 Level Gain Adjustable

-

Storage:

-

20 files (up to 99 values for each file)

-

Communication:

-

Mini-USB interface

-

Calibration Mode:

-

Zero-point, Two-point

-

Measurement Unit:

-

Metric/Imperial unit selectable

-

Power Supply:

-

Two "AA" size

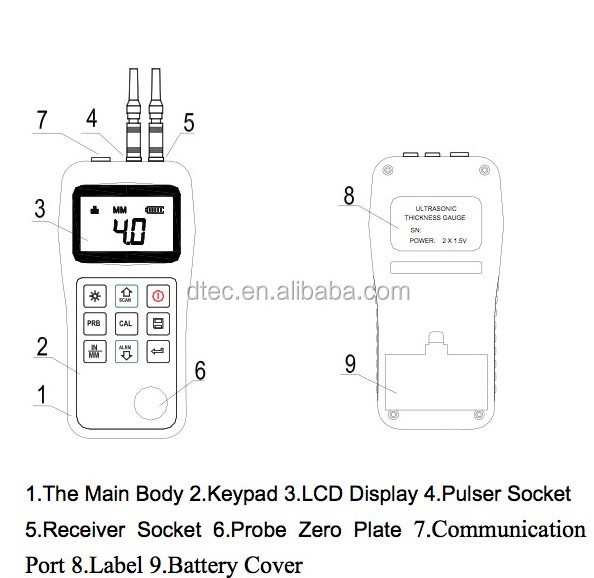

DT210 is an economical and foundational ultrasonic thickness gauge among all models, It is capable of measuring the thickness of various materials with accuracy 0.1mm, or 0.01 inches.

- Capable of performing measurements on a wide range of material;

- Four selectable probes available for special application;

- Probe-Zero function, Sound-Velocity-Calibration function;

- Two-Point Calibration function;

- Two working modes: Single point mode and Scan mode;

- Four measurements readings per second for single point measurement, and ten per second for Scan Mode;

- Coupling status indicator showing the coupling status;

- Auto sleep and auto power off function to conserve battery life.

|

Measuring Range |

0.75~300mm (in Steel)

|

|

Sound Velocity Range

|

1000~9999 m/s.

|

|

Resolution

|

0.1mm

|

|

Accuracy

|

±(0.5%Thickness+0.04)mm, depends on materials and conditions

|

|

Measurement Unit |

Metric/Imperial unit selectable |

|

Displaying Mode |

4.5 digits LCD with EL backlight

|

|

Memory

|

20 files (up to 99 values for each file)

|

|

Power Supply |

Two “AA” size, 1.5 volt alkaline batteries. 100 hours typical working time (EL backlight off). |

|

Dimension

|

31.5x24.5x8.5cm(LxWxH)

|

|

Packing Weight |

1.5 KG |

|

Model

|

Freq.

(MHZ)

|

Dia.

(mm)

|

Measuring Range

|

Lower limit

|

Description

|

|

N02

|

2.5

|

14

|

3.0mm~300.0mm(In Steel)

|

20

|

For thick, highly attenuating, or highly scattering materials

|

|

N05

|

5

|

10

|

1.2mm~230.0mm(In Steel)

|

Φ20mm×3.0mm

|

Normal Measurement

|

|

N05

/90°

|

5

|

10

|

1.2mm~230.0mm(In Steel)

|

Φ20mm×3.0mm

|

Normal Measurement

|

|

N07

|

7

|

6

|

0.75mm~80.0mm

(In Steel)

|

Φ15mm×2.0mm

|

For pipe wall or small curvature pipe wall

|

|

HT5

|

5

|

12

|

3~200mm (In Steel)

|

30

|

For high temperature (lower than 300℃)

|

|

Material

|

Sound Velocity

|

|

|

In/us

|

m/s

|

|

|

Aluminum

|

0.250

|

6340-6400

|

|

Steel, common

|

0.233

|

5920

|

|

Steel, stainless

|

0.226

|

5740

|

|

Brass

|

0.173

|

4399

|

|

Copper

|

0.186

|

4720

|

|

Iron

|

0.233

|

5930

|

|

Cast Iron

|

0.173-0.229

|

4400-5820

|

|

Lead

|

0.094

|

2400

|

|

Nylon

|

0.105

|

2680

|

|

Silver

|

0.142

|

3607

|

|

Gold

|

0.128

|

3251

|

|

Zinc

|

0.164

|

4170

|

|

Titanium

|

0.236

|

5990

|

|

Tin

|

0.117

|

2960

|

|

Epoxy resin

|

0.100

|

2540

|

|

Ice

|

0.157

|

3988

|

|

Nickel

|

0.222

|

5639

|

|

Plexiglas

|

0.106

|

2692

|

|

Polystyrene

|

0.092

|

2337

|

|

Porcelain

|

0.230

|

5842

|

|

PVC

|

0.094

|

2388

|

|

Quartz glass

|

0.222

|

5639

|

|

Rubber, vulcanized

|

0.091

|

2311

|

|

Teflon

|

0.056

|

1422

|

|

Water

|

0.058

|

1473

|

Standard Packing List:

|

No

|

Items

|

Qty.

|

Note

|

|

1

|

Main Unit |

1

|

|

|

2

|

Standard Probe |

1

|

Model: N05/90° |

|

3

|

Coupling gel |

1

|

|

|

4

|

Instrument Case |

1

|

|

|

5

|

Manual Book, Quality Certificate, Guarantee Card |

1

|

|

|

6

|

Alkaline battery |

2

|

AA size |

|

Optional Accessories |

1

|

Transducer: N02 |

|

2

|

Transducer: N07 |

|

|

3

|

Transducer: HT5 |

|

|

4

|

Mini thermal printer |

|

|

5

|

Print cable |

|

|

6

|

Data Pro Software (support the 64 system) |

|

|

7

|

Communication Cable |

Optional Probes:

Every set of our equipement will be carefully tested and double checked steps by steps before being packed and delivery,as we all know that among such fierce international competition,only 100% good quality and stable performance can finally attain the customer's trust.Hence,we will always put the equipment calibraton job in the first place while manufacturing.