- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1330*650*1300 mm

-

Weight:

-

1000 KG

-

Place of Origin:

-

Shandong,China

-

Voltage:

-

220V/380V

Quick Details

-

Machinery Capacity:

-

100-500KG/H

-

Brand Name:

-

SM

-

Year:

-

2024

-

Dimension(L*W*H):

-

1330*650*1300 mm

-

Weight:

-

1000 KG

-

Place of Origin:

-

Shandong,China

-

Voltage:

-

220V/380V

Product Description

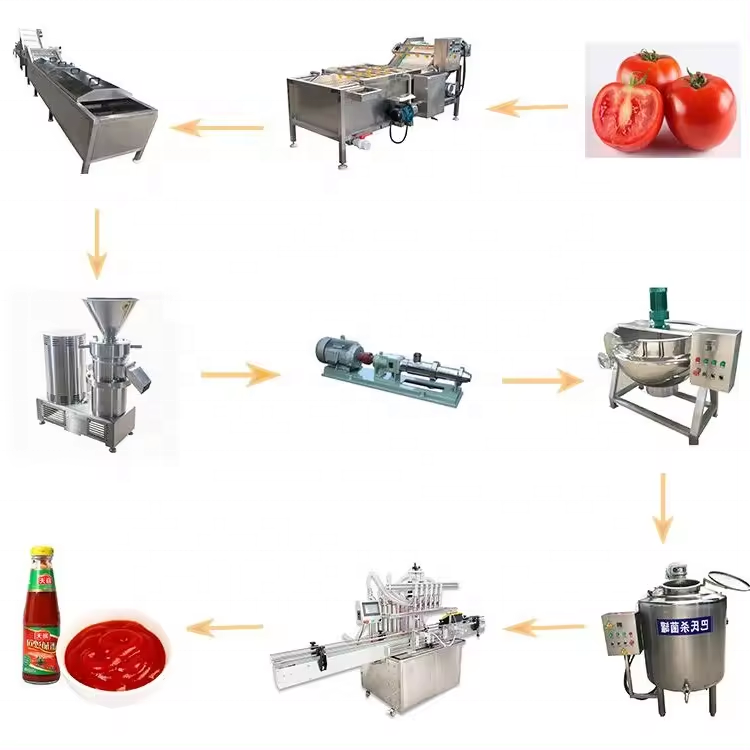

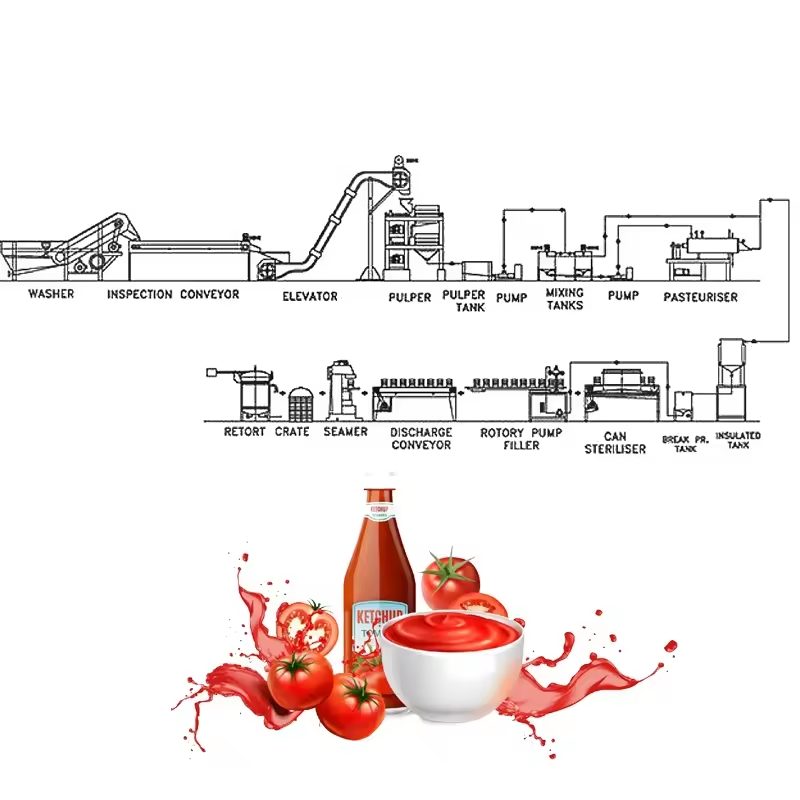

Ketchup is a sauce-like concentrated product of fresh tomatoes. It has a bright red sauce and has the unique flavor of tomatoes.It is a distinctive condiment and is generally not directly consumed. Ketchup is made by crushing, beating, removing the skin and seeds and other hard substances from ripe red tomatoes, then concentrating, filling and sterilizing. Ketchup is often used as a cooking condiment for fish, meat and other foods. It is a good seasoning product that enhances color, adds acid, helps freshness, and fragrant.

OUR FEATURE:

1)All the machines are made of SUS 304, 316L optional.

2)Finally Packaging: usually, filled with aseptic bag in drum or aseptic bag in box. and then packed with small packaging. such as: plastic bottle, glass bottle, can, jar, tetra pack etc.

3)The line is also suitable for processing the fruits that share the similar characteristics.

4)Adopt 'hot-break' or 'cold-break' techniques to produce fruit paste which is different viscosity.

5)Tubular UHT Sterilizer and aseptic filling machine, produce high-quality fruit paste products.

1)All the machines are made of SUS 304, 316L optional.

2)Finally Packaging: usually, filled with aseptic bag in drum or aseptic bag in box. and then packed with small packaging. such as: plastic bottle, glass bottle, can, jar, tetra pack etc.

3)The line is also suitable for processing the fruits that share the similar characteristics.

4)Adopt 'hot-break' or 'cold-break' techniques to produce fruit paste which is different viscosity.

5)Tubular UHT Sterilizer and aseptic filling machine, produce high-quality fruit paste products.

|

No.

|

Equipment Name

|

Function

|

|

1

|

Picking Belt

|

Manually remove unqualified, worm-eye, and moldy tomatoes

|

|

2

|

Tomato Washing Machine

|

Under the action of bubbles and spray, the picked tomatoes are cleaned, mainly to remove the surface sediment

|

|

3

|

Tomato Crushing Machine

|

Crush the washed tomatoes to facilitate the later beating work

|

|

4

|

Tubular Preheater

|

Increase temperature of slurry to achieve preheating, inactivating enzymes and protecting color

|

|

5

|

Tomato Pulping Machine

|

Pitting and beating fruits after pre-cooking.

|

|

6

|

Buffer Tank

|

|

|

7

|

Concentrator

|

|

|

8

|

Tubular sterilizer

|

Sterilization of concentrated tomato paste

|

|

9

|

Finished tank

|

Ketchup cache after sterilization

|

|

10

|

Tomato Paste Packing Machine

|

Ketchup packaging work

|

Our Advantages

Packaging & Shipping

Contact us

Hot Searches