- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Model Number:

-

Carbide Saw Blade

-

Type:

-

Machine Blade

-

Blade Material:

-

Tungsten Carbide Steel

-

Advantage:

-

High Efficiency

Quick Details

-

Finishing:

-

Other

-

Size:

-

27-67mm, Request

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

OEM

-

Model Number:

-

Carbide Saw Blade

-

Type:

-

Machine Blade

-

Blade Material:

-

Tungsten Carbide Steel

-

Advantage:

-

High Efficiency

Place of Origin:Benxi,China

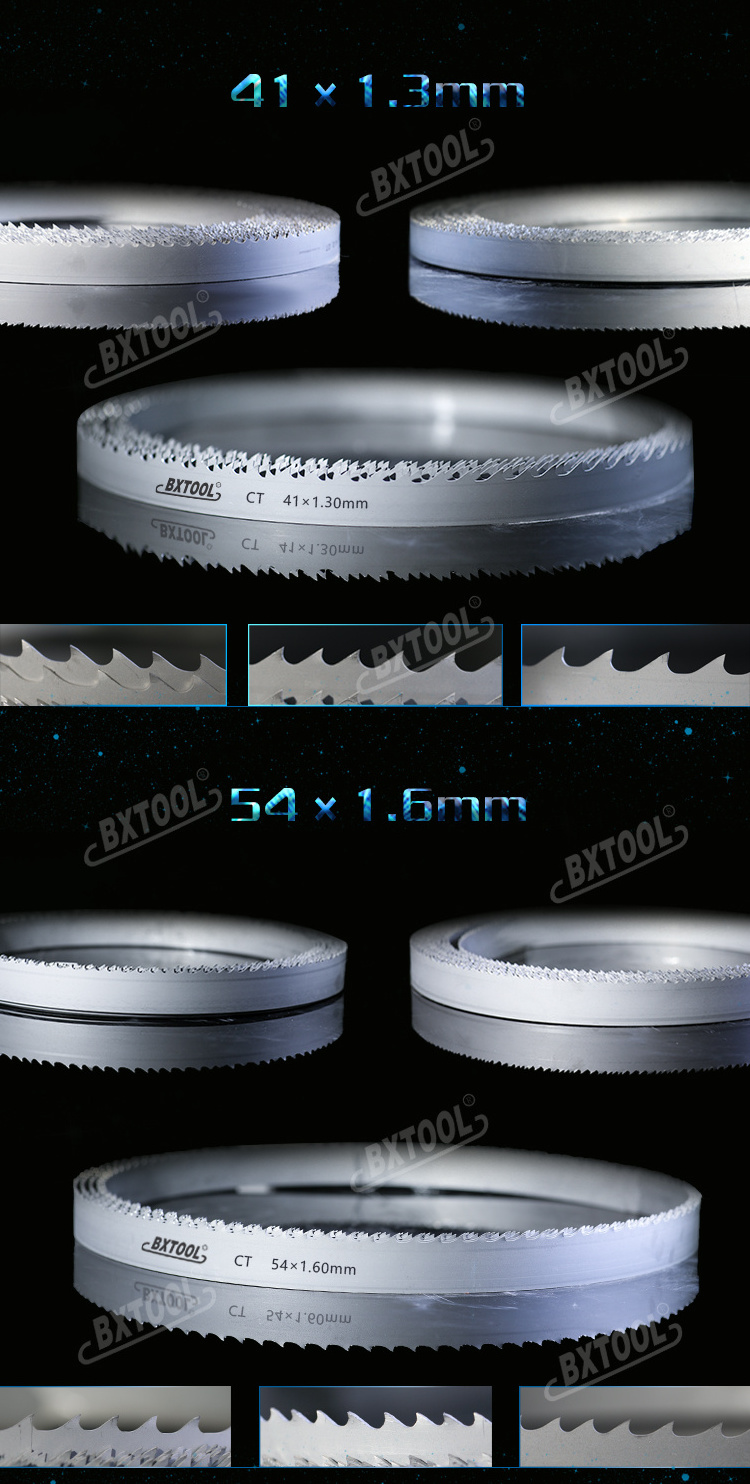

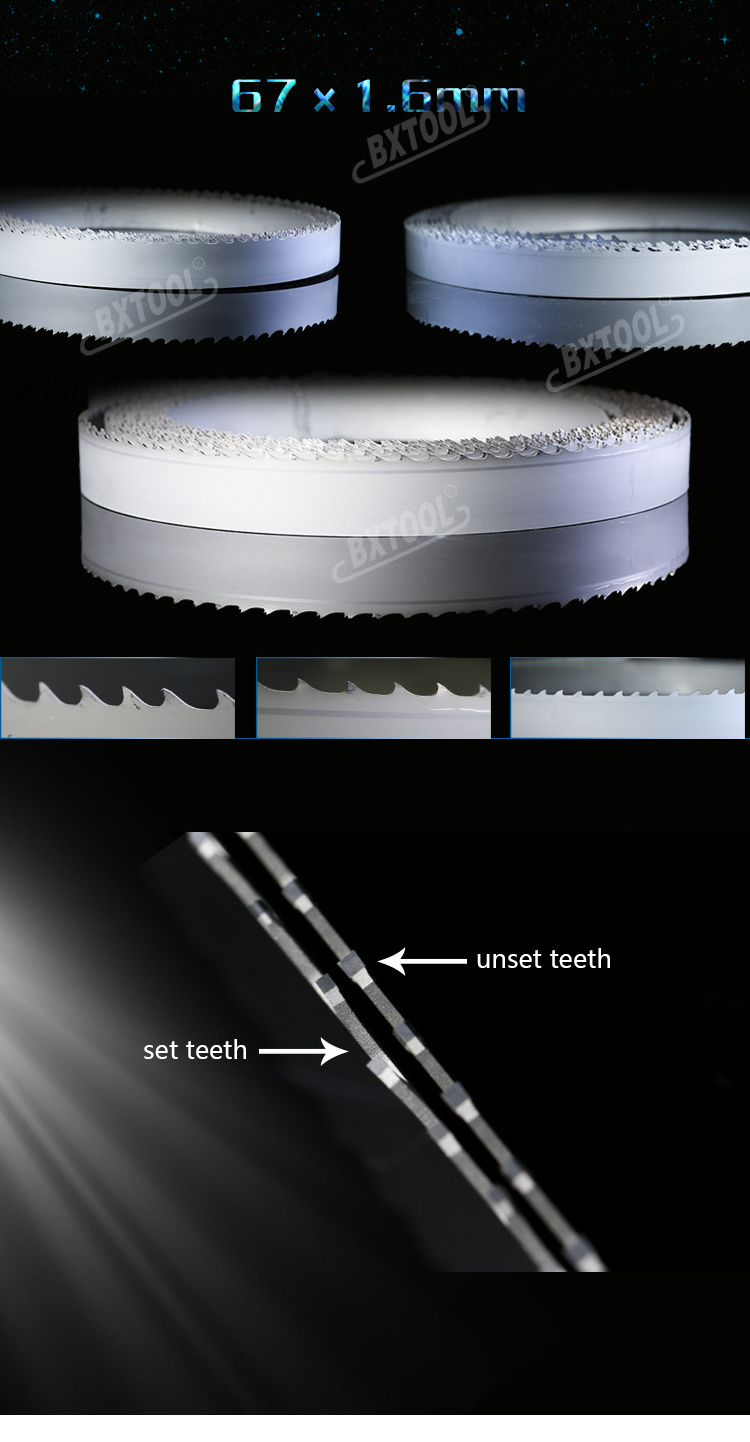

Grade: CT

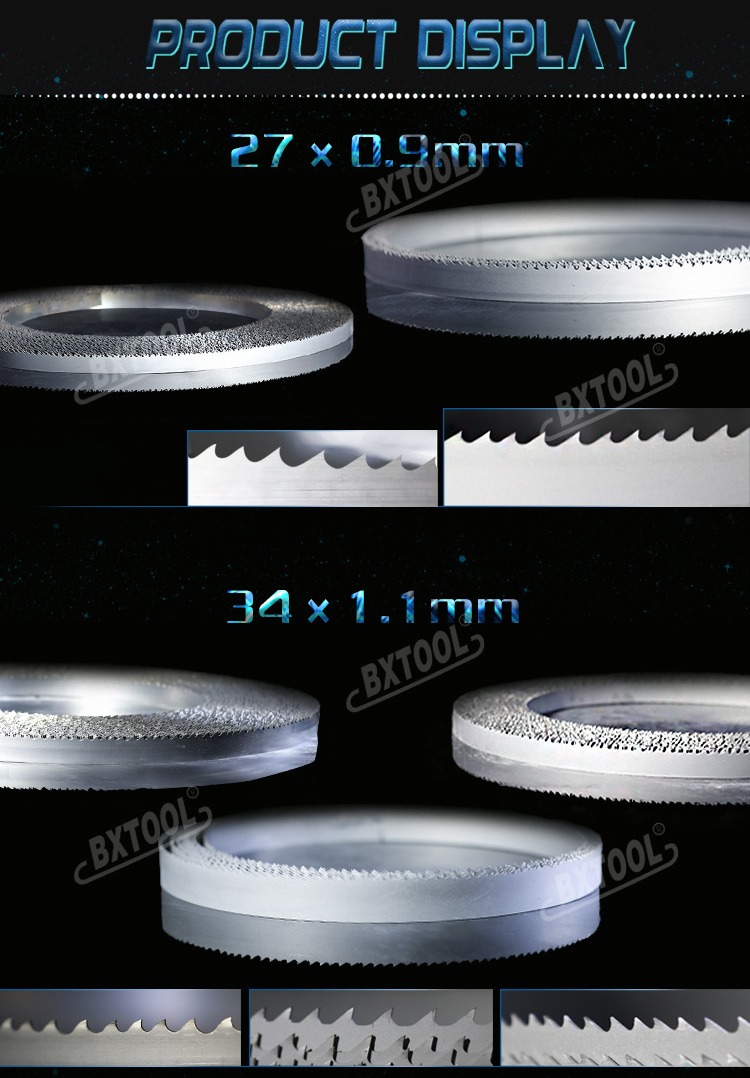

Size: 27×0.90mm inch 1×0.035 ; 34×1.1mm inch 1 1/4×0.042 ; 41 ×1.30mm inch 1 1/2×0.05 ; 54×1.60mm inch 2×0.063 ; 67 ×1.60mm inch 2 5/8×0.063

Brand Name:BXTOOL brand

TPI: 3/4T , 2/3T ; 3/4T , 2/3T , 1.4/2.0T ; 3/4T , 2/3T , 1.4/2.0T , 1/1.25T ; 3/4T , 2/3T , 1.4/2.0T , 1/1.25T ; 1.4/2.0T , 1/1.25T , 0.75/1T

Application : High hardness steel, surface hardened steel, superalloy, titanium alloy, nickel alloy, composite graphite, precious and high hardness wood.

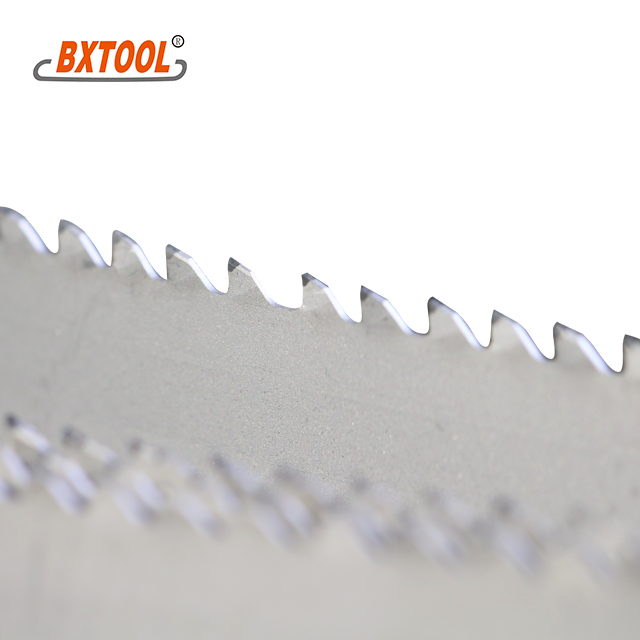

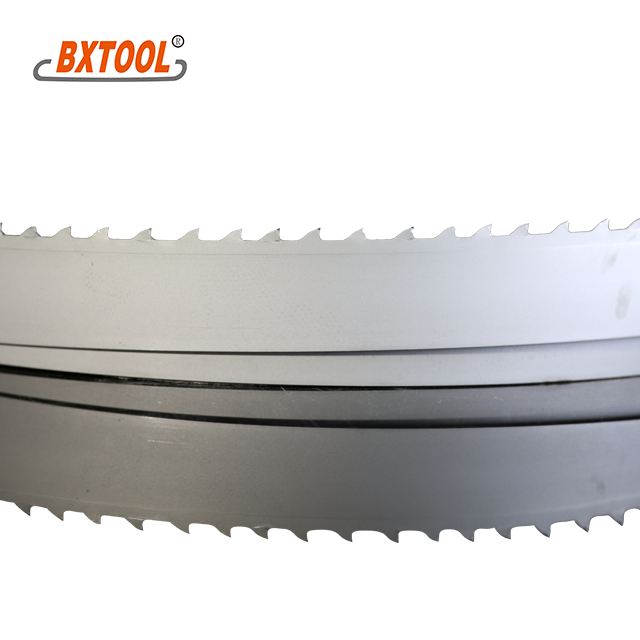

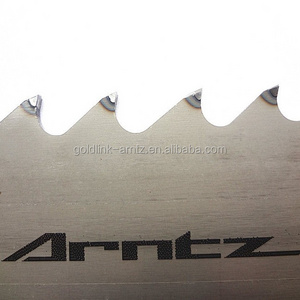

Introduction : It is the most advanced product in the series of bimetal band saw blade.The welding strength can be increased by 50%. The hardness reaches 92.1 (HRA), welding strength 0.45KNxmm, the back is high alloy material of Austria Bohler company, it has the high strength and toughness high alloy material of Bohler company, and has high strength. Good toughness, strong anti-deformation force, Germany's advanced resistance direct welding technology, in the process of cutting tooth back stronger. The scientific design of the tooth shape makes the workload of each tooth more reasonable. Precise and unique population grinding makes the sawing smoother and the sawing surface smoother.

Supply Ability: 10 million meters per year (0.85million meters per month)

Size: 27×0.90mm inch 1×0.035 ; 34×1.1mm inch 1 1/4×0.042 ; 41×1.30mm inch 1 1/2×0.05 ; 54×1.60mm inch 2×0.063 ; 67 ×1.60mm inch 2 5/8×0.063

For welding loops: 10pcs or 20pcs or 50pcs packed in one box.

For coils: 100m or 200m packed in one box or wooden box.

Shipping date: If there are requested sizes in our warehouse stock, normally shipment within 7 days. If over 5000meters, the delivery time is within 2 weeks. Special orders, Please contact with sales assistance or asking it by email on line.

Delivery way: by air, by sea, by train, by courier etc.

1. Your enquiry can be replied in 24 working hours;

2. Well-trained and experienced staffs to answer all your enquires;

3. OEM&ODM, we can help you to design and put into product;

4. Protection of your sales area, ideas of design and all your

private information.Depending on the strict management

system and consummate After-sales service system, we

provide consumer a warm and appropriate service.