- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

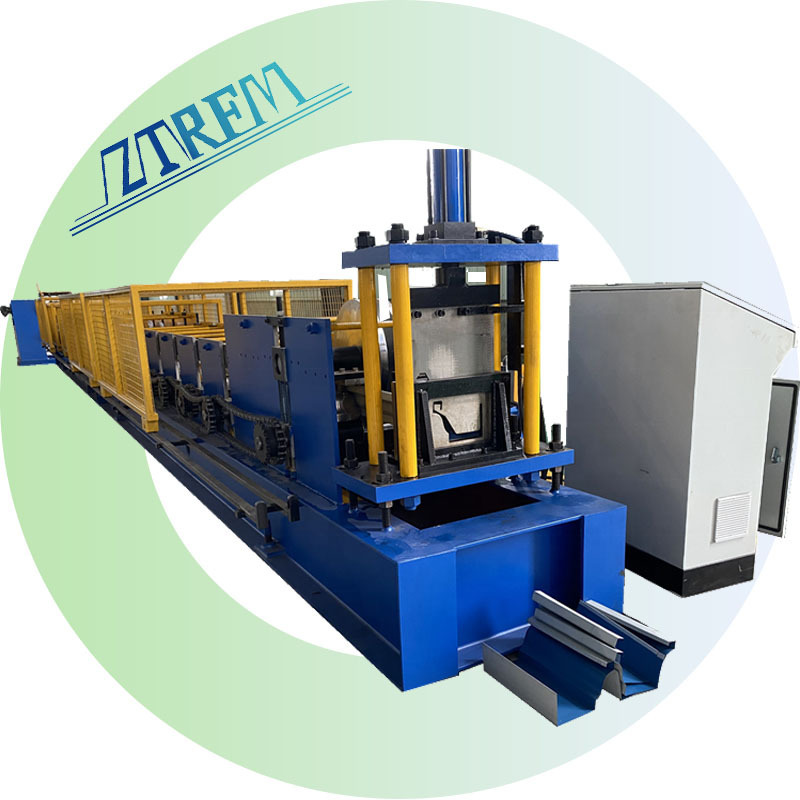

ZTRFM

-

Voltage:

-

380V/50HZ/3HP

-

Weight:

-

5000 kg

-

Feeding width:

-

Other

-

Raw material:

-

Color Steel Sheet

-

Control system:

-

PLC(imported Brand)

-

Plc:

-

DETLA

-

Advantage:

-

High Efficent

-

Product name:

-

gutter

-

Color:

-

Client's Request

-

Thickness:

-

0.3--0.8mm

-

Motor brand:

-

Lichao

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

Quick Details

-

Type:

-

gutter downspout machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

12-15m/min

-

Rolling thinckness:

-

0.3-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

380V/50HZ/3HP

-

Weight:

-

5000 kg

-

Feeding width:

-

Other

-

Raw material:

-

Color Steel Sheet

-

Control system:

-

PLC(imported Brand)

-

Plc:

-

DETLA

-

Advantage:

-

High Efficent

-

Product name:

-

gutter

-

Color:

-

Client's Request

-

Thickness:

-

0.3--0.8mm

-

Motor brand:

-

Lichao

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

Hot sale roof gutter machine rain collecting gutter making machine

This roof gutter roll forming machine is for steel or aluminum sheet cold form industries. It can form rain gutter profiles according to customer’s requirement continuously, automatically cut to length. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production. Therefore, it is really a new type of energy-saving and high-effective equipment for metal rain gutters. And it has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good appearance and so on.

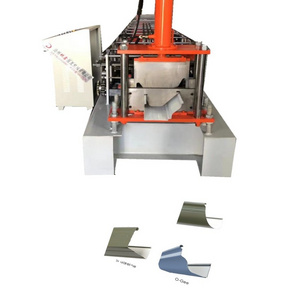

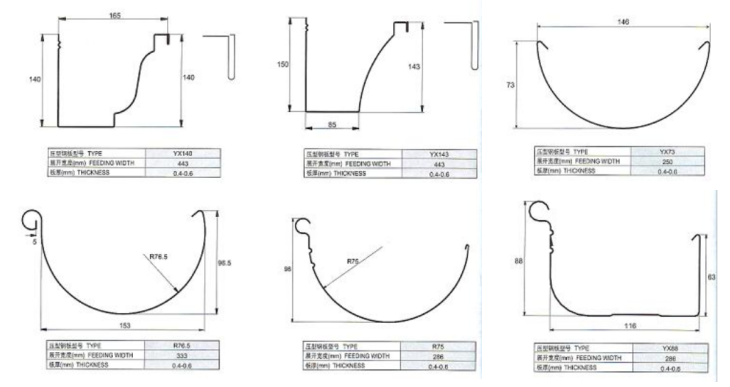

Here are some popular drawings of USA hot sale metal roof gutter roll forming machine :

| 1 | Machine name |

Hot sale roof gutter machine rain collecting gutter making machine

|

| 2 | Dimension | 5500*1600*1500mm |

| 3 | Weight | 3.5T |

| 4 | Total power | 8KW |

| 6 | Voltage | 380V/50HZ/3PH |

| 7 | Forming steps | 16 steps |

| 8 | Forming speed | 12-15m/min |

| 9 | Material thickness | 0.3-0.8mm |

| 10 | Tolerance | ±1mm |

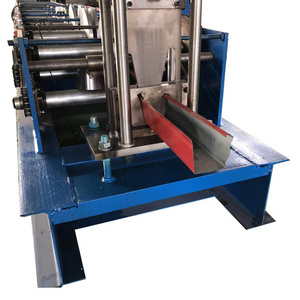

Main pictures :

Final products :

Product application scenarios:

Main parts of our machines: