- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TH 32-60

-

Product name:

-

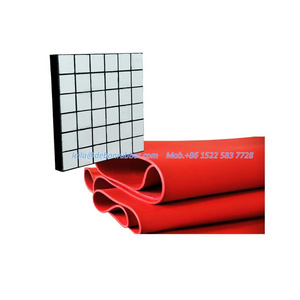

Steel Plate and Rubber Backed Ceramic Wear Liner / Lining

-

Alumina Content:

-

92% / 95% al2o3

-

Shape:

-

Rectangular / Square plate

-

Rubber:

-

Natrual rubber/PE

-

Moh's Hardness:

-

9

-

Water Absorption:

-

0.01

-

Mode of Ceramic Shaped:

-

Dry Pressing

-

Application:

-

Protection liner

-

Ceramic Forming Temperature:

-

1550℃

-

Process:

-

Hot Vulcanization

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Supereal

-

Model Number:

-

TH 32-60

-

Product name:

-

Steel Plate and Rubber Backed Ceramic Wear Liner / Lining

-

Alumina Content:

-

92% / 95% al2o3

-

Shape:

-

Rectangular / Square plate

-

Rubber:

-

Natrual rubber/PE

-

Moh's Hardness:

-

9

-

Water Absorption:

-

0.01

-

Mode of Ceramic Shaped:

-

Dry Pressing

-

Application:

-

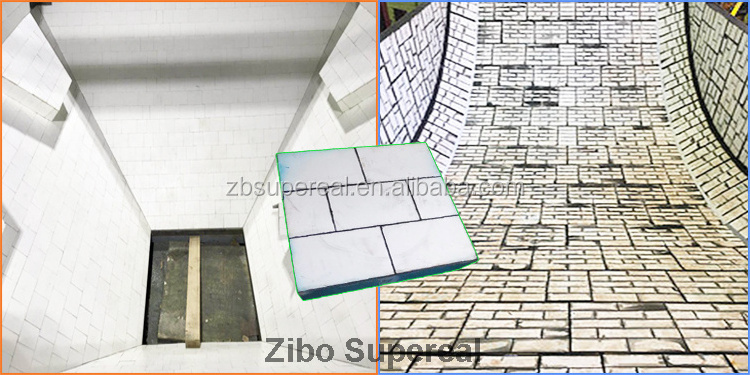

Protection liner

-

Ceramic Forming Temperature:

-

1550℃

-

Process:

-

Hot Vulcanization

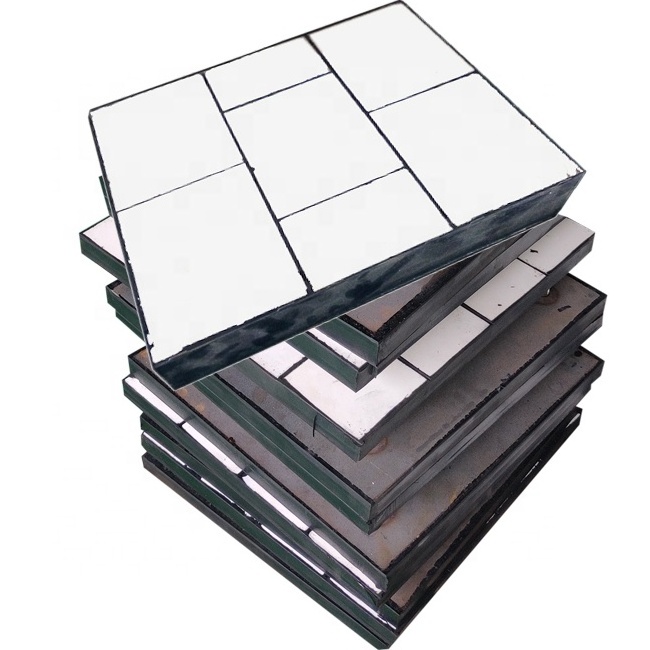

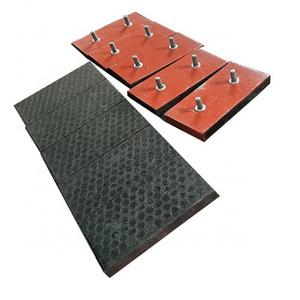

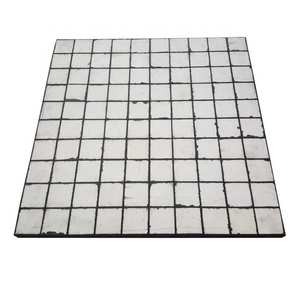

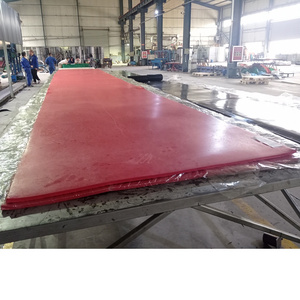

Steel Plate and Rubber Backed Ceramic Wear Liner / Lining

1, Dimension & Specification:

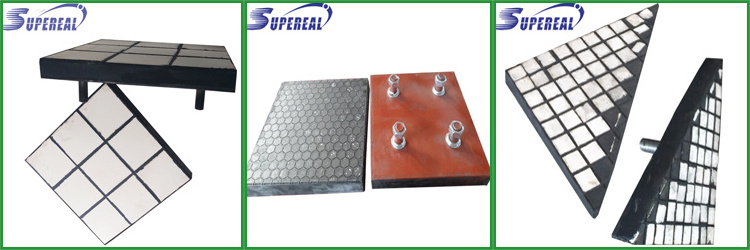

Through vulcanization, the alumina ceramic plates or ceramic tiles are embedded into the special rubbers (and steel) to form a Steel Plate and Rubber Backed Ceramic Wear Liner / Lining , the first kind is rubber backed ceramic plate, which will be fixed on the abrasive surface of equipments by high-strength adhes ive , and the other is rubber and steel backed ceramic plate, it is composed of rubber,alumina ceramic plate and steel plate, which will be fixed on the abrasive surface of equipment by bolts welded in the steel plate

2, Specification of Steel Plate and Rubber Backed Ceramic Wear Liner / Lining:

| Sizes | Length/Width | Ceramic Thickness | Rubber Thickness | Steel Thickness |

| 250×250×15mm | 250/250mm | 5mm | 5mm | 5mm |

| 300×300×16mm | 300/300mm | 8mm | 4mm | 4mm |

| 500×500×25mm | 500/500mm | 15mm | 4mm | 6mm |

| 500×600×30mm | 500/600mm | 20mm | 6mm | 4mm |

| 600×300×35mm | 600/300mm | 25mm | 6mm | 4mm |

| 400×500×38mm | 400/500mm | 25mm | 7mm | 6mm |

| 300×400×50mm | 300/400mm | 30mm | 12mm | 8mm |

| 300×300×63mm | 300/300mm | 50mm | 7mm | 6mm |

| 300×400mm×130mm | 300/400mm | 100mm | 18mm | 12mm |

|

|

|||

|

Items |

Index |

Items | Index | |

|

Alumina content |

≥92% |

Tensile Strength |

≥26 MPa | |

|

Bulk Density |

≥3.63g/cm³ |

Break Extension |

≥500% | |

|

Rockwell Hardness (HRA) |

≥90 |

Shore Hardness |

55-65HA | |

|

Compressive Strength |

≥850MPa |

Break Permanent Deformation |

≤24% | |

|

Fracture Toughness |

≥4.8MPa.M1/2 |

Rubber and Ceramic Adhesion Force (Shearing Stress)

|

≥3.0MPa | |

|

Bending Strength |

≥290MPa |

Temperature Resistance |

≤100℃ | |

|

Thermal Conductivity 20℃ |

20W/m.k |

Rubber Aging Life |

≥8 years | |

|

Coefficient of Thermal Expansion |

7.2×10 -6 m/×m.k |

Gap Between Tile |

0.8-2.0mm | |

| Young's Modulus 20℃ | 277GPa | Rubber Edge | 1.5-2.0mm | |

|

Specification ( L×W×T) |

Thickness Details |

| 300×300×12mm | 6mm ceramic + 6mm rubber |

| 250×250×15mm | 10mm ceramic +5mm rubber |

| 250×300×16mm | 12mm ceramic +4mm rubber |

| 500×500×15mm | 10mm ceramic + 5mm rubber |

| 500×400×20mm | 12mm ceramic + 8mm rubber |

| 500×500×30mm | 20mm ceramic + 10mm rubber |

| 300×300×63mm | 50mm ceramic + 13mm rubber |

| 500×500×63mm | 50mm ceramic + 13mm rubber |