- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Customize

-

Material:

-

PPE/PS+GF30

-

Certificates:

-

ISO9001:2008.REACH.ROHS

-

Application:

-

Injection

-

Type:

-

Compounding material

-

Shape:

-

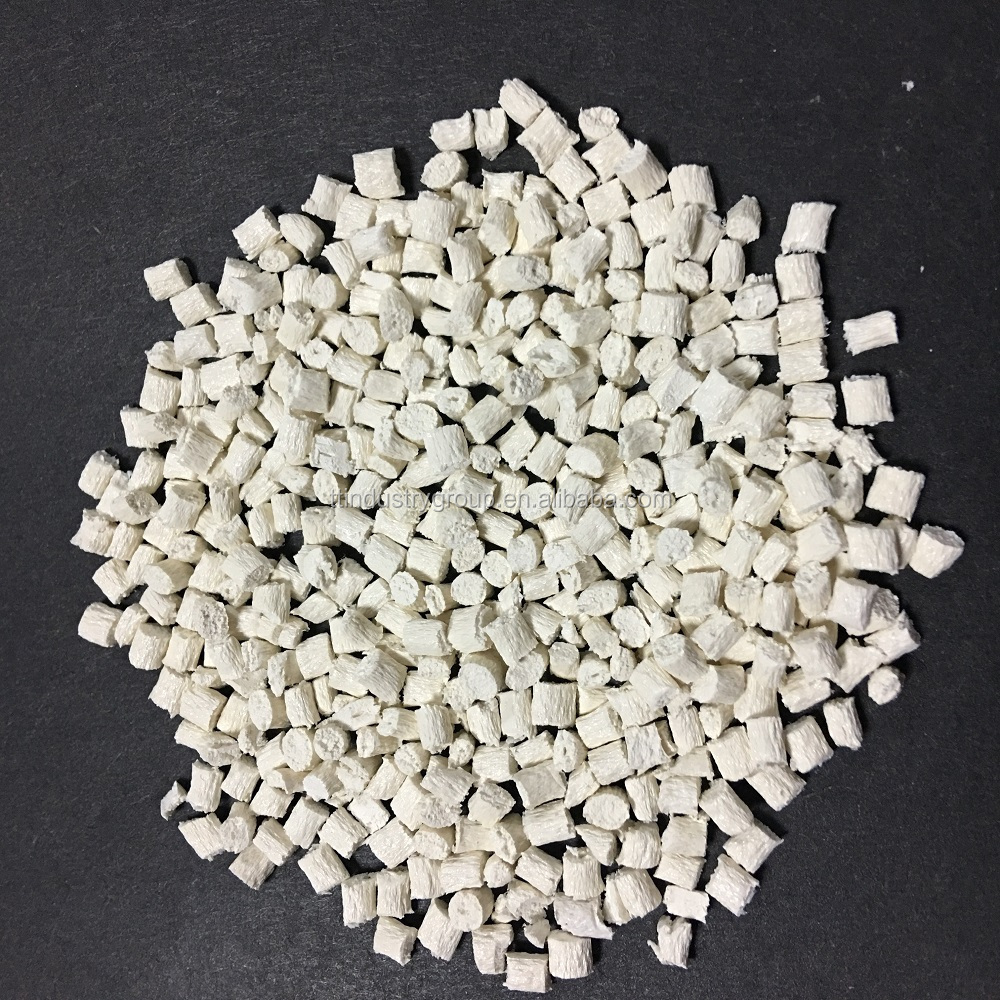

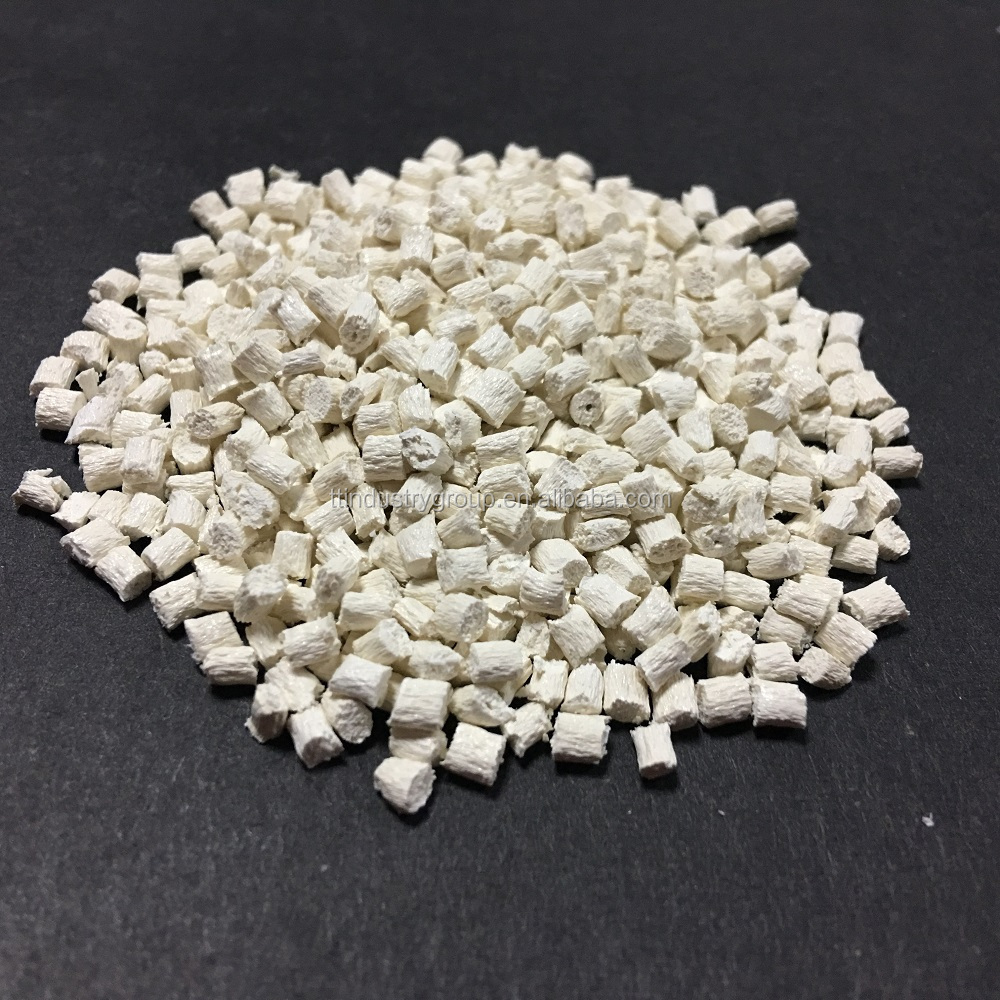

Pellets/granules

-

Package:

-

25kg/bag

-

Aplication:

-

Injection Molding

-

Additive:

-

Heat resistance;High rigidity

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GC

-

Model Number:

-

I010-G6

-

Color:

-

Customize

-

Material:

-

PPE/PS+GF30

-

Certificates:

-

ISO9001:2008.REACH.ROHS

-

Application:

-

Injection

-

Type:

-

Compounding material

-

Shape:

-

Pellets/granules

-

Package:

-

25kg/bag

-

Aplication:

-

Injection Molding

-

Additive:

-

Heat resistance;High rigidity

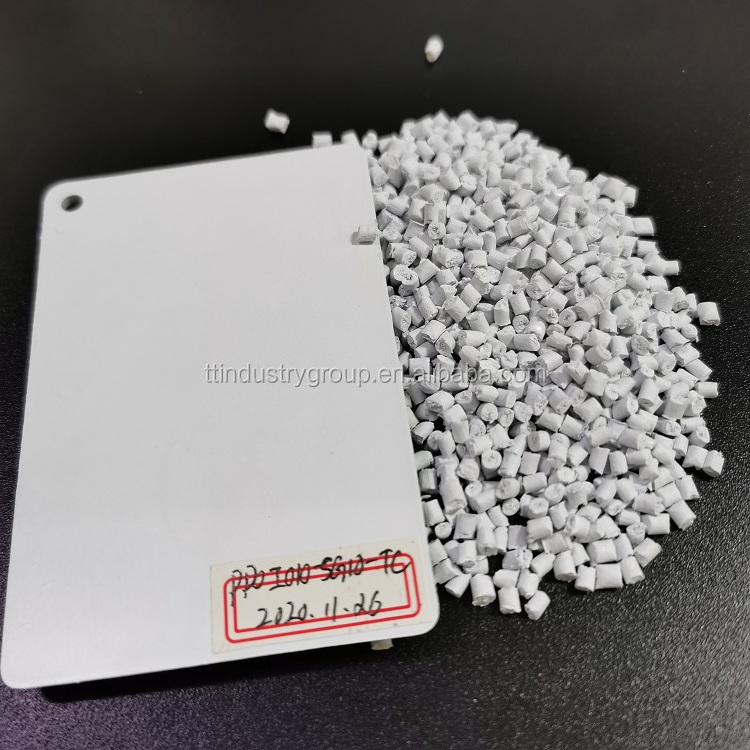

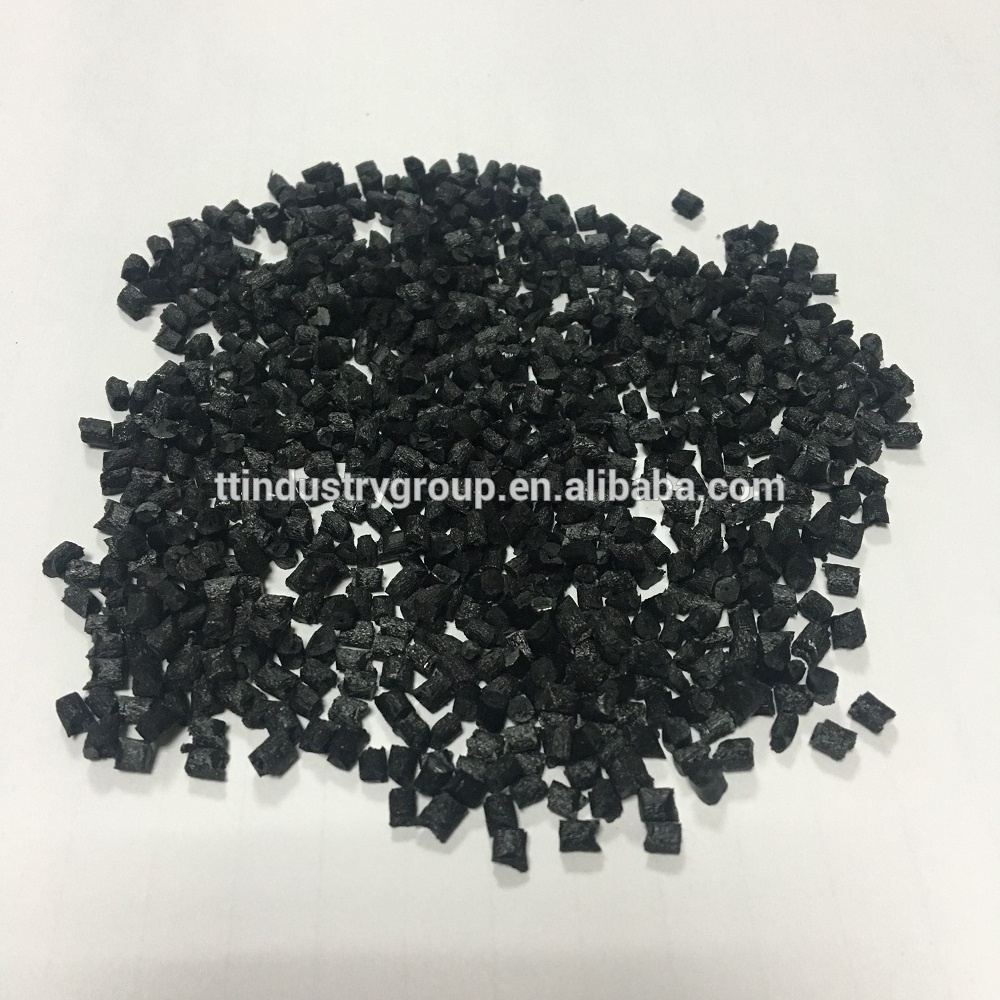

PPO/PS GF30 plastics material

I010-G30 is a PPE/PS with 30% glass fiber,high rigidity and heat resistance.

| Properties | Standard | Condition | Unit | Value |

| Physical Properties | ||||

| Specific Gravity | ASTM D792 | 23℃ | g/cm3 | 1.31 |

| Mold Shrinkage,Flow | ASTM D955 | Cold mold, 48 hrs | % | 0.1-0.4 |

| Mold Shrinkage,Cross-Flow | Cold mold, 48 hrs | % | 0.1-0.4 | |

| Moisture Absorption | ASTM D570 | 23 °C; 50 % RH | % | 0.04 |

| MFR | ASTM D1238 | 275°C/5kg | g/10min | 3.2 |

| Mechanical Properties | ||||

| Tensile Strength | ASTM D638 | 50mm/min | Mpa | 130 |

| Elongation at Break | ASTM D638 | 50mm/min | % | 3 |

| Flexural Strength | ASTM D790 | 3mm/min | Mpa | 160 |

| Flexural Modulus | ASTM D790 | 3mm/min | Mpa | 6.4 |

| Izod Impact, Notched | ASTM D256 | J/m | 12 |

PPO/PS GF30 plastics material picture:

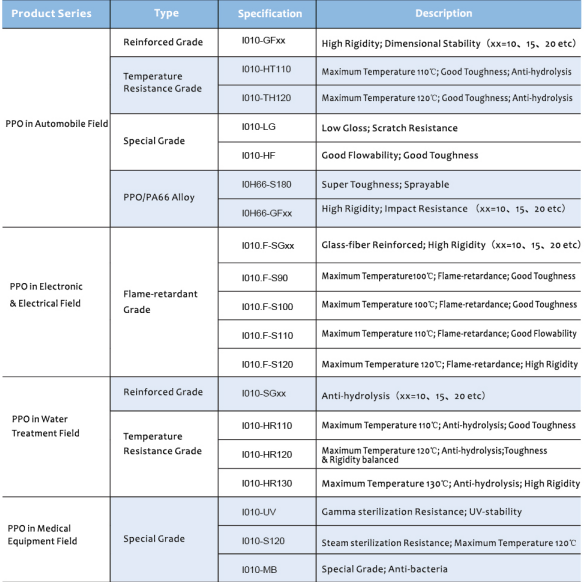

Our PPO series products:

Our Testing Equipment

IC Tray

Electronic and Electrical,Household Electrical Applicance,office Automation Equipment,Automobile,Architecture Materials,aviation & Aerospace,Military Areas.

T&T Industry Group Ltd is a customized engineering plastics company combining of R&D, Design, and Project Development. Currently our focus is on the project devlopement and optimal configuration of different resources, based on the actual situation of the One-Belt and One-Road industrialized countries and current new materials development, and world industrialized situation.

1. Waterproof Design(Dual package, Waterproof bag Inside)

2. Sealed Packaging,Impact resistant (Kraft paper bag+PE/Aluminum liner)

3. Customized package (25kg/bag or 500kg/bag)

4. Water-proof , Anti-breaking,Anti-extrusion . Anti-heavy throw

5. Transporation by sea, the sample can be shipped by air.

Service procedure:

Consulting--solutions--quotation--sending samples--quality check--placing orders-- customization--deliver goods--after sell services

1.Technical backgroud Sales can provide in-time and professional responses to customers' inquiries.

2. Real-time Quality Inspection Tour in full production process;

3. Certicate of Analysis provided for each delivery of goods

4. After-sales quality tracking and feedback

5. Customers complains processing management system to guarantee the consistant improving service to each client.

1,Samples leading time : 1-2 weeks after passed our test;

2,Bulk order leading time : 2-4 weeks ( customized materials ,seldom in stock)

3,Samples are delivered by FEDEX DHL ,TNT , UPS,Samples fee will be refund when the first bulk order comes .

4,Payment Term: T/T or L/C at sight;

5,Minimum Order Quantity: 1 MT

6,Delivery Time: Lead-time is around 7-14 working days after we receive the advance payment. It varies according to different products and quantity.

7,The quality standard refers to the sample. And quality issues we provide free tech-support

--