- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

jingye

-

Machinery Capacity:

-

50-600KPH

-

Machinery Function:

-

cooking, heating, mixing

-

Name:

-

Steam Jacket Kettle

-

Heating type:

-

Steam Heating

-

Application scope:

-

Sauce /Jam / Paste Making

-

Usage:

-

Cooking & Mixing

-

Application:

-

Food Industry

-

Mixer Type:

-

Scraper Agitator, 0-36RPM

-

Temperature:

-

≤100℃

-

Material:

-

SUS304/316

-

Certification:

-

ISO, CE,

Quick Details

-

Weight (KG):

-

290

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

jingye

-

Machinery Capacity:

-

50-600KPH

-

Machinery Function:

-

cooking, heating, mixing

-

Name:

-

Steam Jacket Kettle

-

Heating type:

-

Steam Heating

-

Application scope:

-

Sauce /Jam / Paste Making

-

Usage:

-

Cooking & Mixing

-

Application:

-

Food Industry

-

Mixer Type:

-

Scraper Agitator, 0-36RPM

-

Temperature:

-

≤100℃

-

Material:

-

SUS304/316

-

Certification:

-

ISO, CE,

Product Details

JingYe Steam Kettles, also called jacketed kettle, have a special hemisphere bottom with full jacket layer, and heated through a true hemispherical jacket layer, ensure that the material is heated evenly in the process of mass cooking.

And thanks to the hemispherical bottom, the heating area is larger, helping customers get faster heating effects with less energy.

In addition, non direct heating and accurate temperature control, foods won’t get burned and no need constant monitoring.

Besides, we have a variety of mixer type, for different customers to achieve the ideal mixing effect.

Detail Image

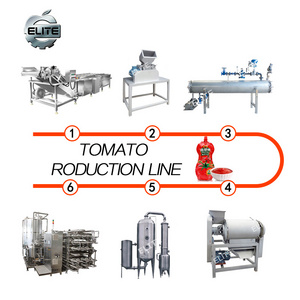

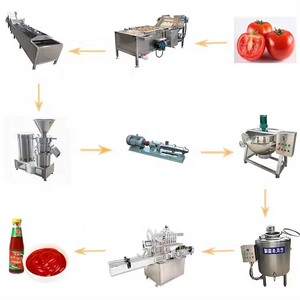

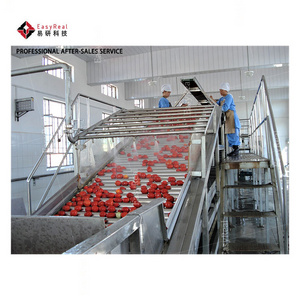

Application

Product Parameters

Product Display

Factories and Certificates

Jiangxi Jingye Machinery Technology Co., Ltd

Jiangxi Jingye Machinery Technology Co., Ltd. is a high-tech private enterprise from China.

The company integrates technology research and development, engineering design, equipment manufacturing and engineering installation. It has gathered domestic advanced talents in the fields of machinery, engineering, technology and automatic control.By introducing the design concept of safety, environmental protection and intelligence, the company continues to independently develop and innovate technology, and has become a high-quality supplier of food, beverage, chemical and biological pharmaceutical equipment.

The company is mainly engaged in sandwich pot, cooking pot, sterilization pot, cheese tank, mixing tank and other food production and processing equipment.

The company is committed to providing the best machines, advanced technology and high-quality services to all customers who support the company.

FAQ

1.Q:Are you a manufacturer or a trading company?

A:We are a professional food machinery manufacturer for more than 10 years.

2.Q:How long is the warranty period of the product?

A:This is twelve months.

3.Q:If the machine makes an error, how to solve it?

A:Video guidance. If it doesn't work, we will send our engineers to solve overseas problems.

4.Q:What is the delivery time after placing the order?

A:It usually takes about 25-30 days after we receive your deposit. If it is a large machine, we will try to deliver it within 2

months.

5.Q:How long is the delivery date?

A:FOB, CFR and CIF are optional; This depends on the customer's requirements;

6.Q:What is the minimum order quantity of your machine?

A:1 set.

7.Q:Does the material meet the food requirements?

A:This machine is made of food hygiene grade 304 material, please feel free to place an order

8.Q:How to keep oil leakage of mixing motor?

A:The machine is equipped with oil leakage protection device, so the oil will not leak into the pot and contact the material.

9.Q:What is the material that the agitator contacts with the boiler wall?

A:It is high temperature food grade polytetrafluoroethylene.

A:We are a professional food machinery manufacturer for more than 10 years.

2.Q:How long is the warranty period of the product?

A:This is twelve months.

3.Q:If the machine makes an error, how to solve it?

A:Video guidance. If it doesn't work, we will send our engineers to solve overseas problems.

4.Q:What is the delivery time after placing the order?

A:It usually takes about 25-30 days after we receive your deposit. If it is a large machine, we will try to deliver it within 2

months.

5.Q:How long is the delivery date?

A:FOB, CFR and CIF are optional; This depends on the customer's requirements;

6.Q:What is the minimum order quantity of your machine?

A:1 set.

7.Q:Does the material meet the food requirements?

A:This machine is made of food hygiene grade 304 material, please feel free to place an order

8.Q:How to keep oil leakage of mixing motor?

A:The machine is equipped with oil leakage protection device, so the oil will not leak into the pot and contact the material.

9.Q:What is the material that the agitator contacts with the boiler wall?

A:It is high temperature food grade polytetrafluoroethylene.

Hot Searches