- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v

-

Power:

-

3.2kw

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

84*84*350mm

-

Name:

-

Meat Cutting Machine

-

Application:

-

Meat Processing Equipment

-

Type:

-

Meat Processing Machinery Frozen Meat Slicer

-

Material:

-

304 Stainless Steel

-

Usage:

-

Fresh Frozen Meat Cutting

-

Capacity:

-

600-750kg/h

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YuYun

-

Voltage:

-

220v

-

Power:

-

3.2kw

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

84*84*350mm

-

Name:

-

Meat Cutting Machine

-

Application:

-

Meat Processing Equipment

-

Type:

-

Meat Processing Machinery Frozen Meat Slicer

-

Material:

-

304 Stainless Steel

-

Usage:

-

Fresh Frozen Meat Cutting

-

Capacity:

-

600-750kg/h

Product Description

Introduction:

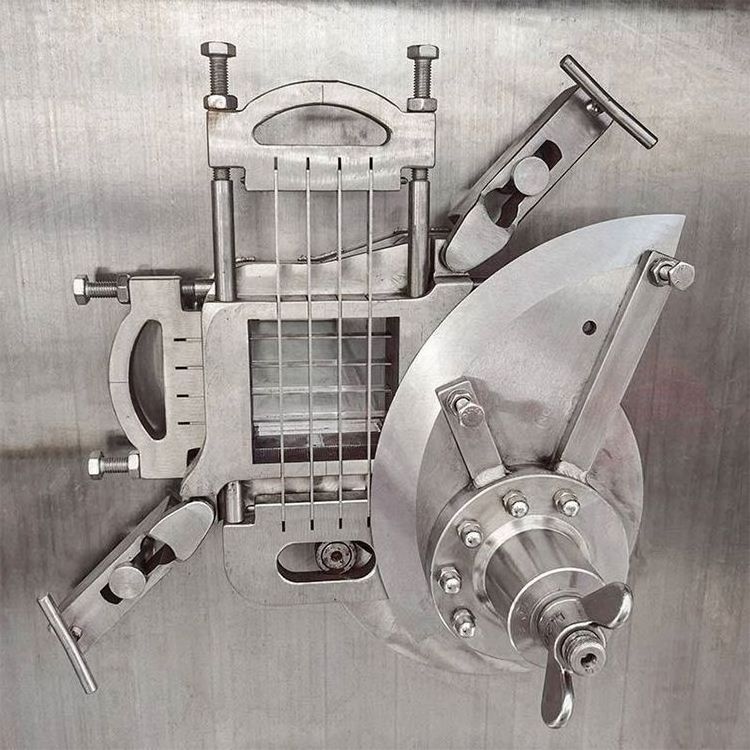

Meet Cutting machine is an important equipment in the production process of meat products. Cut meat, fat and other main raw materials into diced meat required by users, and adjust the size of the knife grid to cut shredded meat, meat slices, and meat diced. The size of the diced meat is determined by the number of blades in the knife grid. The cutting machine is mainly composed of a frame, a reducer, a motor, a tool rest, an eccentric shaft assembly, a main cutter assembly, and a hydraulic system. The main motor drives the main shaft to rotate through the reducer, the fork on the main shaft drives the upper knife grid, the lower knife grid and the left and right reciprocating motion, the material pushed out by the push block is cut into strips, and the main cutter cuts the meat strips into diced meat.

Features:

1.The safety protection performance is good, and the rotating cutter stops working immediately after the front door is opened.

2.All kinds of knives are easy to disassemble, easy to install, easy to clean and replace the knife grid.

3.The side pressure mechanism can increase the amount of meat cut at one time, and help the pre-pressure to reach the set value faster, improving production efficiency. 4.The design of the fork mechanism improves the cutting quality of the product, reduces the noise, and reduces the mechanical failure rate.

5.Adjust the pre-pressure knob to ensure consistent product throughout the cutting process.

6.Meat material can be fed in steps to minimize product squeezing during cutting.

7.Changing the number of blades in the knife grid can cut meat of different sizes, which is easy to combine.

Hot Searches