- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

030

-

Plastic Material:

-

PE / PP / HDPE / PPR / PVC / PP / PS / PRT / ABS / PC / etc.

-

Base:

-

LKM / HASCO / DME

-

Runner:

-

Hot runner / cold runner

-

Lifespan:

-

300,000-1,000,000 shots

-

Cavity:

-

Single-cavity / multi-cavity

-

Offer:

-

OEM & ODM is avalible

-

Certificate:

-

ISO9001: 2008

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Fujian, China, Xiamen China

-

Brand Name:

-

plastic injection mold, JW injection mold

-

Model Number:

-

030

-

Plastic Material:

-

PE / PP / HDPE / PPR / PVC / PP / PS / PRT / ABS / PC / etc.

-

Base:

-

LKM / HASCO / DME

-

Runner:

-

Hot runner / cold runner

-

Lifespan:

-

300,000-1,000,000 shots

-

Cavity:

-

Single-cavity / multi-cavity

-

Offer:

-

OEM & ODM is avalible

-

Certificate:

-

ISO9001: 2008

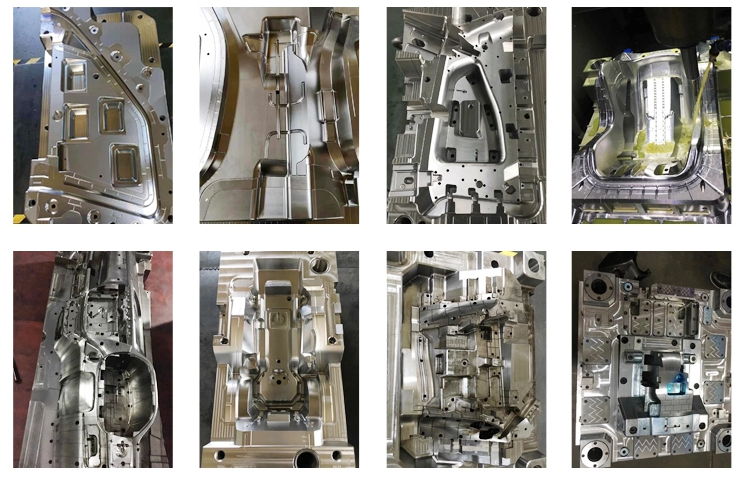

ABS Plastic Mobile Phone power bank case injection plastic mould Cover Shell Case Mould Maker

1. We are professional plastic injection mould designer and manufacturer

2.. Strong R&D dept. and QC team support

3. With over 15 years experienced in mold making

4. Best competitive factory price

5. Welcome any OEM & ODM products

6. Lifetime quality assurance

7. ISO 9001:2008 certified

|

Design

|

As per the customer's 3D drawing(step file) or samples

|

|

Software

|

Auto CAD, CAXA UG, Pro/E

|

|

Material

|

ABS,PC, POM, PP,PA66,ect.

|

|

Service

|

OEM as customer requirement

|

|

Inspection

|

1.100% inspection on critical dimension

|

|

|

2.Third party inspection avaliable upon requirement

|

|

Packing

|

PE+Carton or wooden case

|

Factory

Workshop

Warehouse

Factory Overview

1. Wooden Box for Mould

2. Package for Product

3. Quick Epress

Q: Does your company make mould by yourself?

A: Yes, we are manufacturer with about 15 years of molding experience.

Q: hat type of information is required for quoting a molding project?

A: We’ll need more specifics like the quantity needed, material preference, part prints or CAD files, part samples (if available), description of part application, including UV exposure, chemical resistance,time frame for production parts.

Q:W hat types of molding services do you offer?

A: We design the mold for production, make the mold, and run production parts.

Q: What material should I use for my project?

A:

Most material is application specific. If you don’t have a material selected for your application, we can help and offer some guidance. Often several resins can be sampled but the customer has final approval before proceeding.

Q: What is the typical process of a new project

Q:How long does it take to build an injection mold?

Q:What’s the software you will use to check the drawing? And what’s format of drawing you can check?

Q:Will you send me the free sample?

Q:How to pack the moulds and products?

Mobile: +86 13720889256

E-Mail: info@jweimolding.com