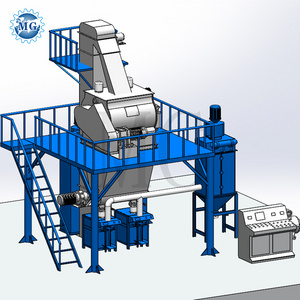

The hydraulic press is the supporting equipment of the planetary mixer or the powerful disperser. Its function is to discharge or separate the high-viscosity rubber produced by the mixer.

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

250L

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Maxwell

-

Voltage:

-

110-480V

-

Dimension(L*W*H):

-

Custom size

-

Power (kW):

-

18.5 kW

-

Marketing Type:

-

New Product 2023

-

Control Method:

-

Button/Touch Screen

-

Stirring system:

-

Fixed Paddle Stirring and PE Blade Scraping

-

Mixing Capacity:

-

1-1000L By Customized

-

Dispersion speed (rotation)::

-

0~2100 rpm adjustable

-

Usage:

-

silicone sealant, battery paste, electronic paste, adhesive,etc

Quick Details

-

Barrel Volume (L):

-

300L

-

Max. Loading Volume (L):

-

250 L

-

Range of Spindle Speed(r.p.m):

-

0 - 75 r.p.m

-

Max. Loading Capacity:

-

250L

-

Weight (KG):

-

2000 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Maxwell

-

Voltage:

-

110-480V

-

Dimension(L*W*H):

-

Custom size

-

Power (kW):

-

18.5 kW

-

Marketing Type:

-

New Product 2023

-

Control Method:

-

Button/Touch Screen

-

Stirring system:

-

Fixed Paddle Stirring and PE Blade Scraping

-

Mixing Capacity:

-

1-1000L By Customized

-

Dispersion speed (rotation)::

-

0~2100 rpm adjustable

-

Usage:

-

silicone sealant, battery paste, electronic paste, adhesive,etc

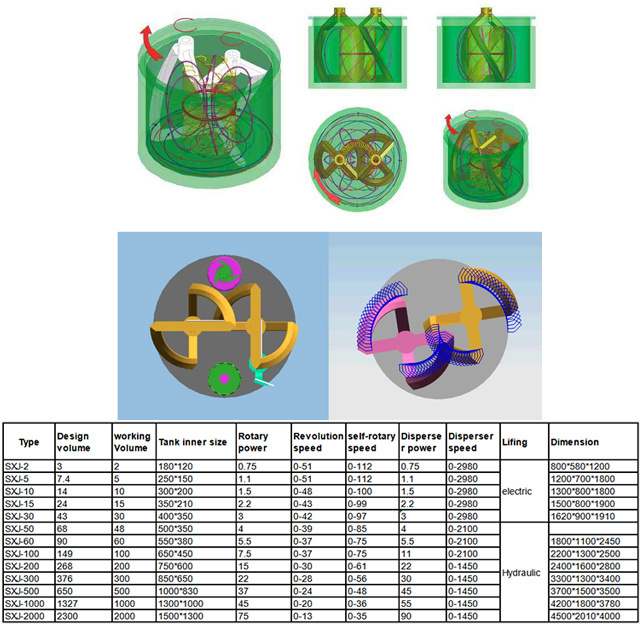

Automatic Hot Melt Mixer Epoxy Resin Mixer Hotmelt Glue Mixing Machines Equipment

250L Planetary Mixer

Product Paramenters

|

Specification

|

|

|

|

|

|

|

|

|

||||||||

|

Mode

|

Design

capacity

|

Work

capacity

|

Barrel

size

|

Revolution

power

|

Revolution speed

|

Rotation speed

|

Dispenser power

|

Dispenser

speed

|

||||||||

|

SXJ-2

|

3

|

2

|

180*120

|

0.75

|

0-51

|

0-112

|

0.75

|

0-2980

|

||||||||

|

SXJ-5

|

7.4

|

5

|

250*150

|

1.1

|

0-51

|

0-112

|

1.1

|

0-2980

|

||||||||

|

SXJ-10

|

14

|

10

|

300*200

|

1.5

|

0-48

|

0-100

|

1.5

|

0-2980

|

||||||||

|

SXJ-15

|

24

|

15

|

350*210

|

2.2

|

0-43

|

0-99

|

2.2

|

0-2980

|

||||||||

|

SXJ-30

|

43

|

30

|

400*350

|

3

|

0-42

|

0-97

|

3.3

|

0-2980

|

||||||||

|

SXJ-50

|

68

|

48

|

500-350

|

4

|

0-39

|

0-85

|

4

|

0-2100

|

||||||||

|

SXJ-60

|

90

|

60

|

550*380

|

5.5

|

0-37

|

0-75

|

5.5

|

0-2100

|

||||||||

|

SXJ-100

|

149

|

100

|

650*450

|

7.5

|

0-37

|

0-75

|

11

|

0-2100

|

||||||||

|

SXJ-200

|

268

|

200

|

750*600

|

15

|

0-30

|

0-61

|

22

|

0-1450

|

||||||||

|

SXJ-300

|

376

|

300

|

850*650

|

22

|

0-28

|

0-56

|

30

|

0-1450

|

||||||||

|

SXJ-500

|

650

|

500

|

1000*830

|

37

|

0-24

|

0-48

|

45

|

0-1450

|

||||||||

|

SXJ-1000

|

1327

|

1000

|

1300*1000

|

45

|

0-20

|

0-36

|

55

|

0-1450

|

||||||||

|

SXJ-2000

|

2300

|

2000

|

1500*1300

|

75

|

0-13

|

0-35

|

90

|

0-1450

|

||||||||

|

Type

|

|

MAX-SXJ-30-300

|

|

|

Tank work volume

|

|

30/50/60/100/200/250/300L

|

|

|

Revolution speed

|

|

0~30 rpm Adjustable

|

|

|

Mixing rotary speed

|

|

0~61 rpm Adjustable

|

|

|

Scraper speed

|

|

0~30 rpm Adjustable

|

|

|

Dispersion speed

|

|

1450rpm Adjustable

|

|

|

Vacuum degree

|

|

- 0.09 Mpa

|

|

Products Description

Product Introduce

The double planetary mixer adopted advanced technology, which is widely used in dispersing mixing middle or high viscosity liquid-liquid/solid-solid/liquid-solid material, such as adhesives, sealant, silicone rubber, glass glue, solder paste, quartz sand,battery paste, electronic slurry, lithium battery slurry, polyurethane, coating, pigment, dyestuff, synthetic resin rubber,ointment and etc for for electronics, chemical,construction and agricultural industries.which the viscosity is app. from 5000cp to 1000000cp.

Planetary Mixer Structure:

Double Twist Mixing Head

Double-layer high speed dispersing head

Scrapper Emulsifying head

The mixing head combination forms are tailored for different process. Impeller blade, Dispersing disc, Twist impeller and Scraper are optional.

Planetary Mixer Structure:

Double Twist Mixing Head

Double-layer high speed dispersing head

Scrapper Emulsifying head

The mixing head combination forms are tailored for different process. Impeller blade, Dispersing disc, Twist impeller and Scraper are optional.

Lifting system

The electric lifting function of the lid can effectively stir the materials under closed conditions. It is easy to clean in the

pot and easy to operate.

pot and easy to operate.

Spiral stirrer, scraper, dispersion plate

Various types can be configured according to customer requirements

Electric or hydraulic lifting tank

Electric or hydraulic lifting tank

Control system

There is a digital time relay, which can adjust the speed and working time of the mixer according to the process and

characteristics of different products. emergency button. The electrical control cabinet integrates all the power on, off,

control,voltage, current, and frequency conversion speed of the machine, and the mixing time setting is reasonably centralized,and the operation is clear at a glance.

characteristics of different products. emergency button. The electrical control cabinet integrates all the power on, off,

control,voltage, current, and frequency conversion speed of the machine, and the mixing time setting is reasonably centralized,and the operation is clear at a glance.

Hydraulic press machine

Working Principle

Planetary power mixer is a kind of new high-efficiency mixing and stirring equipment with no dead spot. It features unique and novel stirrer mode, with two or three stirrers as well as one or two auto scrapers inside the vessel. While revolving around the axle of the vessel, the stirrers also rotate around its own axis at different speeds, to achieve complicated movement of strong shearing and kneading for materials inside the vessel. Besides, the scraper inside the equipment revolves around the axle of the vessel, scraping the materials adhering to the wall for mixing and achieving better effects. The vessel adopts special sealing

structure, capable of pressurized and vacuumized mixing, with excellent exhaust and bubble removal effects. Vessel jacket can be heating or cooling according customer’s requirements. The equipment is sealed excellently. The vessel cover can be hydraulically lifted and lowered, and vessel can be moved freely for ease of operation. Furthermore, the stirrers and scraper can rise with the beam and fully detach from vessel body, for ease of cleaning.

structure, capable of pressurized and vacuumized mixing, with excellent exhaust and bubble removal effects. Vessel jacket can be heating or cooling according customer’s requirements. The equipment is sealed excellently. The vessel cover can be hydraulically lifted and lowered, and vessel can be moved freely for ease of operation. Furthermore, the stirrers and scraper can rise with the beam and fully detach from vessel body, for ease of cleaning.

Main Features

(1) Glue mixing machine, the materials are mixed rapidly under the action of strong shearing and kneading force. Various agitators

(blade type, twist type, claw type, frame type etc) are in option based on materials with different viscosity and different specific gravity.

(2) Adopt hydraulic cylinder as lifting actuators. Control the mixer up, stop and down through controlling the valve, simple operation with high stability.

(3) There is scraper on the planetary frame rotating together with the planetary frame, it clings to the container and scrape the materials on the wall off continuously, and ensure without mixing dead corner and excellent mixing result.

(4) Options for explosion-proof type, closed type, heating type, with PLC intelligent control type, etc.

5) Reliable airproof tank can mix in vacuum and decompression surroundings.

6) Tank with jacket for heating and cooling demand by input oil or water.

7) Changeable inner tank with precision process, easy cleaning.

8) The shaft motion on orbital revolution and axial rotation at the same time, which can make the material mixed evenly. Material options for SS304, SS316L or special Spraying materials.

Product display

Application

Applications

1. Energy: all kinds of battery paste, paste material (lithium battery, nickel chromium battery, nickel metal hydride batteries,fuel cells, power battery, etc.);

2.electronic appliances, solder paste, ceramic slurry, magnetic material, silica gel ink, electronic adhesive, PVC plastic,

electronic potting glue, hot melt adhesive, all kinds of precious metal powder, slurry;

3.chemicals:A variety of sealant, adhesive, silicone sealant, polysulfide sealant, structure of insulating glass sealant,

waterproof sealant, sealant, anaerobic adhesive, stone glue, plastic mould, etc.), synthetic resin, rubber, printing ink, putty,

abrasives (cream), wax products, synthetic rubber, synthetic resin, all kinds of powder materials, ceramic pigment;

4.pharmaceuticals: all kinds of soft ointment, polymer gel (medical post, colds, pediatric antifebrile fast post), ice stick, eye,teeth;

5.cosmetics, daily chemical product: cream, lipstick, lotion, gel, facial mask, mascara, foundation, nail polish, toothpaste,

soap.

6.food: all kinds of paste, paste mixing, seasoning, jam, chocolate syrup.

2.electronic appliances, solder paste, ceramic slurry, magnetic material, silica gel ink, electronic adhesive, PVC plastic,

electronic potting glue, hot melt adhesive, all kinds of precious metal powder, slurry;

3.chemicals:A variety of sealant, adhesive, silicone sealant, polysulfide sealant, structure of insulating glass sealant,

waterproof sealant, sealant, anaerobic adhesive, stone glue, plastic mould, etc.), synthetic resin, rubber, printing ink, putty,

abrasives (cream), wax products, synthetic rubber, synthetic resin, all kinds of powder materials, ceramic pigment;

4.pharmaceuticals: all kinds of soft ointment, polymer gel (medical post, colds, pediatric antifebrile fast post), ice stick, eye,teeth;

5.cosmetics, daily chemical product: cream, lipstick, lotion, gel, facial mask, mascara, foundation, nail polish, toothpaste,

soap.

6.food: all kinds of paste, paste mixing, seasoning, jam, chocolate syrup.

Hot Searches