The automatic roller coating machine AJL.R90 is independently developed and designed by Suzhou Angem Precision Machinery Co., Ltd. and has independent intellectual property rights. It is mainly used for auto parts, seal frames, shock absorber metal parts, hardware, electrical insulation, etc. Full body spray for smaller parts. This spraying equipment has many advantages such as high degree of automation, environmental protection, high productivity, energy saving, etc., and has obtained the utility model patent

certificate: ZL2013 2 0319639 7.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V±10% 50Hz

-

Power:

-

14.5 KW

-

Dimension(L*W*H):

-

1980(L)*1400(W)*1470(H)mm

-

Weight (KG):

-

2000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

customized

-

Part Rotate Speed:

-

0~600rpm/min

-

Part Number:

-

40 Piece/20 Piece Optional

-

Part Size:

-

10~200mm

-

Air Pressure:

-

0.6Mpa

-

Application:

-

metal parts spraying and painting

-

Product name:

-

Save Paint Automatic Metal Glue Sprayer for Small Parts

-

Technology:

-

Automatic Spraying Line

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Machine Type:

-

Coating machine, Coating Equipment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Angem

-

Voltage:

-

380V±10% 50Hz

-

Power:

-

14.5 KW

-

Dimension(L*W*H):

-

1980(L)*1400(W)*1470(H)mm

-

Weight (KG):

-

2000

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

customized

-

Part Rotate Speed:

-

0~600rpm/min

-

Part Number:

-

40 Piece/20 Piece Optional

-

Part Size:

-

10~200mm

-

Air Pressure:

-

0.6Mpa

-

Application:

-

metal parts spraying and painting

-

Product name:

-

Save Paint Automatic Metal Glue Sprayer for Small Parts

-

Technology:

-

Automatic Spraying Line

-

After Warranty Service:

-

Field maintenance and repair service

Product Introduction

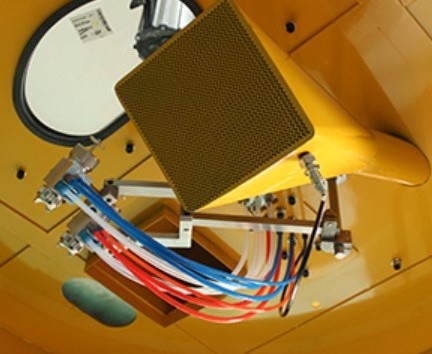

Angem automatic roller coating machine AJL.R90

Features

New design concept and precision processing technology .The appearance is exquisite, beautiful and generous.

The fully enclosed spraying mode and multi-stage exhaust gas filtration can reach high-quality emission standards.

The technology-specific spraying control system allows the parts to obtain a good surface quality.

Automatic product unloading, energy saving and environmental protection is a professional solution for large quantities of small parts and automatic spraying.

Adopting a fully imported glue supply system and imported automatic spray gun to provide reliable guarantee for spraying quality.

Adopt all imported electrical control system and unique design mechanism. It provides a reliable guarantee for the long-term stable operation of the equipment, and the technical indicators of the product are more stable.

Product Paramenters

|

PRODUCT PROERTIES

|

TECHNICAL PARAMETER

|

|

Productive tempo

|

10 - 40 min/barrel

|

|

Diameter of rotary drum

|

900 mm

|

|

Maximum load of rotary drum

|

50 kg or 20 - 40 L

|

|

Drying temperature

|

normal temperature - 120℃

|

|

Warming-up temperature

|

normal temperature - 120℃

|

|

Autorotation rate of rotary drum

|

10 - 30 rpm/min

|

|

Air source pressure

|

0.6 Mpa

|

|

Motor power

|

5 kw

|

|

Heating power

|

10 kw

|

|

Total power

|

15 kw

|

|

Machine weight

|

1.5 ton

|

|

External dimension of the coater

|

L2600mm * W1800mm * H2500mm

|

Applications

Decorative spraying:

for pen sticks, dovetail clips, wooden toys, hearing aids, zipper heads, buttons, fishing hooks, springs, bottle caps and other small parts.

Anti-corrosion spraying:

for nuts and screws bolts, small nails, fasteners small hardware and other parts of the surface anti-corrosion.

Sliding performance improvement spraying:

for O-ring water-based lubrication coating, PTFE lubrication coating spraying.

Spraying of adhesives:

for oil seal skeleton, automotive shock absorber bushing skeleton, brake seal, engine seal

Spraying for electrical insulation:

for soft core, hard core, toroidal core, battery cap and other insulation coating.

Hot Searches