- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AMOR

-

Voltage:

-

220V/380V

-

Power:

-

11KW

-

Weight:

-

1450 kg

-

Marketing Type:

-

Hot Product 2022

-

Application:

-

Custom Corrugated Box, Plastic Corrugated Box

-

Product Name:

-

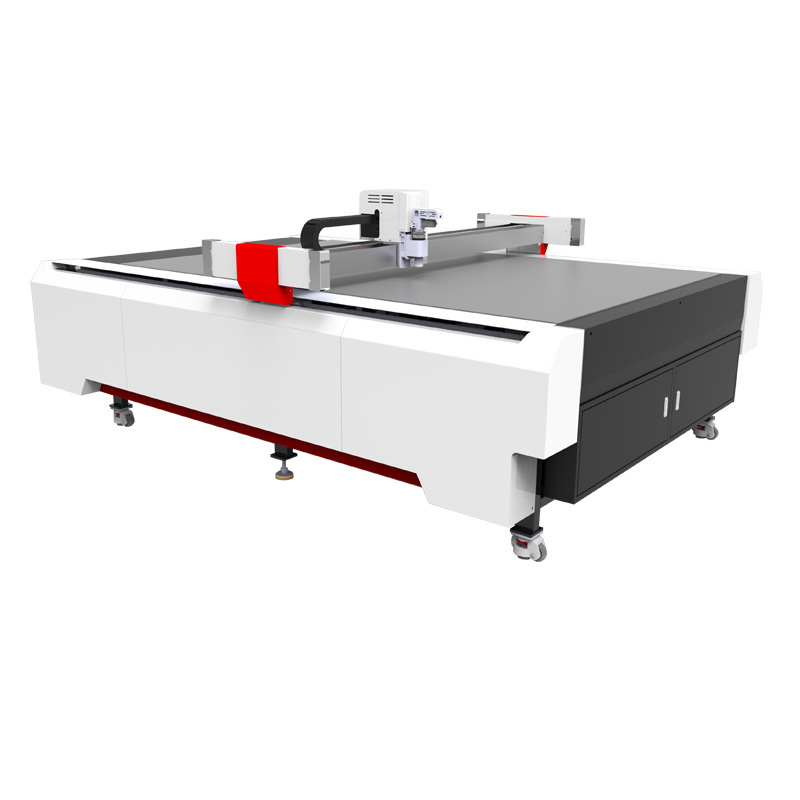

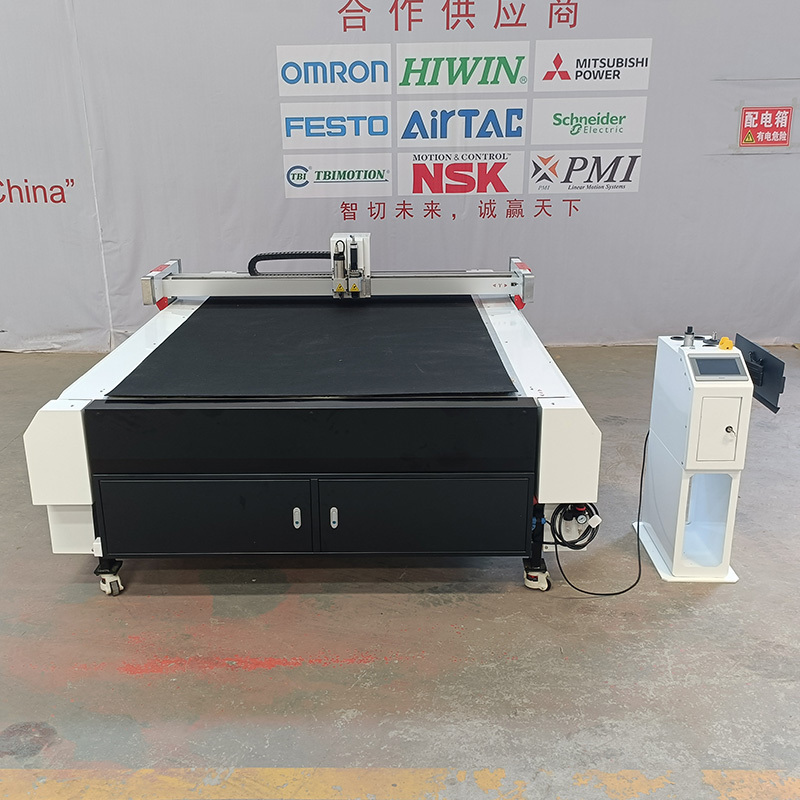

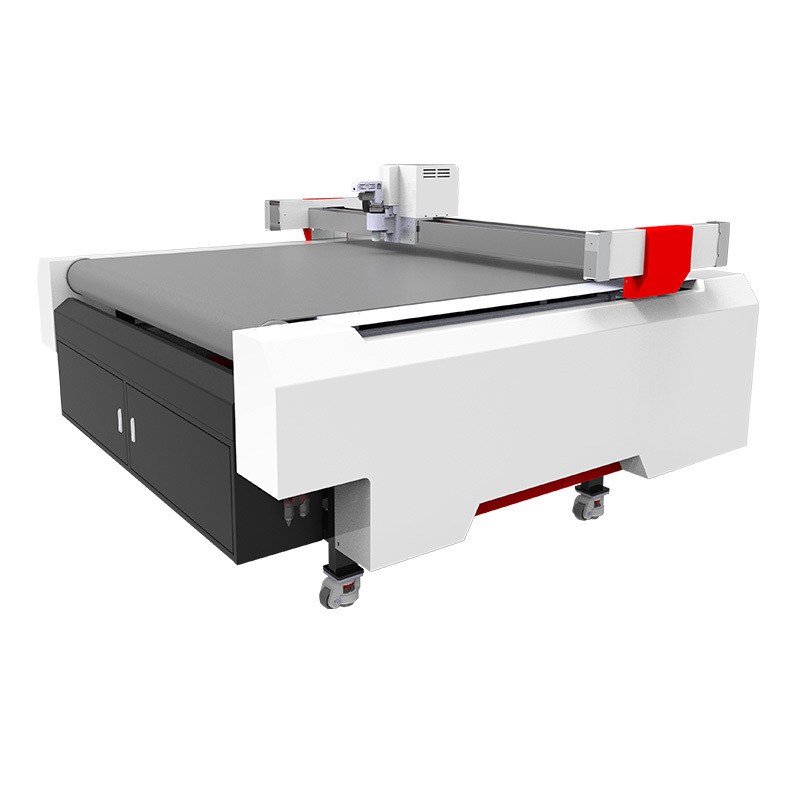

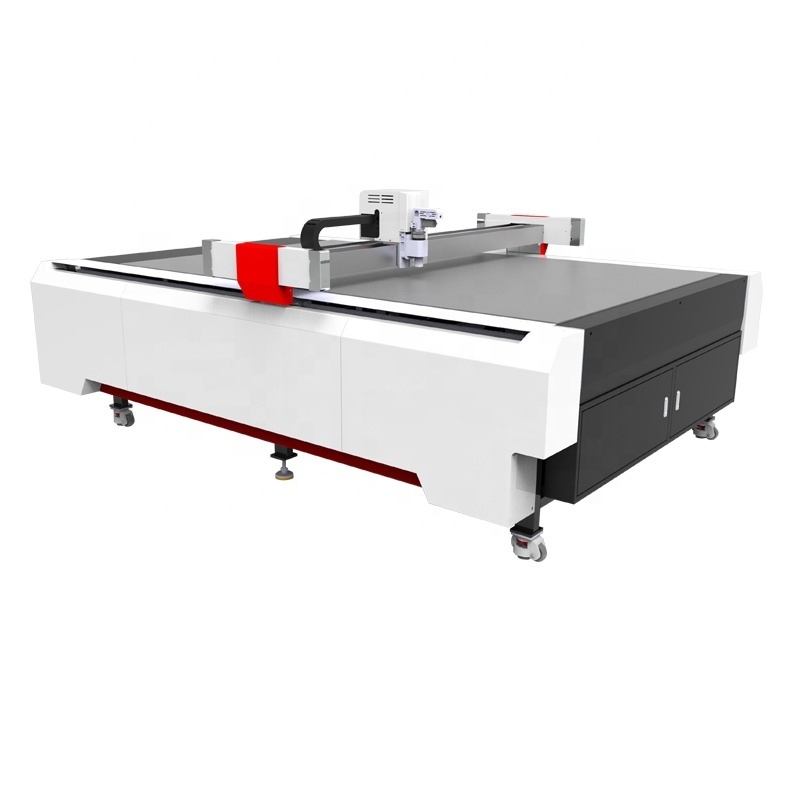

CNC Oscillating Knife Cutting Machine

-

Driving System:

-

Servo motor + reducer

-

Advantage:

-

High-quality accessories, scientific installation

-

Working Area:

-

1600mmX2500mm

-

Cutting Thickness:

-

45mm-110mm

-

Safety Device:

-

Infrared sensors

-

Repeated Accuracy:

-

≤0.1mm

-

Tool Configuration:

-

Creasing Cutter+POT+EOT

Quick Details

-

Production Capacity:

-

50 m/min

-

Product Type:

-

Carton Making Machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AMOR

-

Voltage:

-

220V/380V

-

Power:

-

11KW

-

Weight:

-

1450 kg

-

Marketing Type:

-

Hot Product 2022

-

Application:

-

Custom Corrugated Box, Plastic Corrugated Box

-

Product Name:

-

CNC Oscillating Knife Cutting Machine

-

Driving System:

-

Servo motor + reducer

-

Advantage:

-

High-quality accessories, scientific installation

-

Working Area:

-

1600mmX2500mm

-

Cutting Thickness:

-

45mm-110mm

-

Safety Device:

-

Infrared sensors

-

Repeated Accuracy:

-

≤0.1mm

-

Tool Configuration:

-

Creasing Cutter+POT+EOT

Products Description

CNC Cardboard Cutting Machine for Cutting Creasing Grooving Corrugated Boxes Honeycomb Cardboard Cutting Machine

AMOR 1610MK

The effective processing format is 1600mmX1000mm, which can be used for corrugated box proofing and small batch customized production. Small size, small footprint.

AMOR 1625MK

The effective processing width is 1600mmX2500mm, which can accommodate two pieces of corrugated cardboard for cutting and creasing at the same time. The large working width of the machine is used to achieve efficient processing.

|

Model

|

AMOR-1610 MK

|

|

AMOR-1625 MK (Support customization)

|

|

|||

|

Working area

|

1600mmX1000mm

|

|

1600mmX2500mm

|

|

|||

|

Operation properties

|

Online / offline operation; continuous cutting with high efficiency, 7*24 with zero downtime

|

|

|

|

|||

|

Safety device

|

Infrared adopted; sensitive response; safe and reliable

|

|

|

|

|||

|

Multi-function tool

|

Vibrating knife full cut, semi-cut cutting, indentation, drawing mark, cursor positioning, camera positioning edge cutting, V-groove various angle cutting

|

|

|

|

|||

|

Applicable materials

|

Cardboard, gray cardboard, KT board, Chevron board, honeycomb board, car sticker, light sheet, PP adhesive, inkjet cloth, flag cloth, various corrugated cardboard, EPE foam, EVA, PVC board, acrylic board, etc.

|

|

|

|

|||

|

Transmission system

|

Mitsubishi servo motor + precision reducer + Taiwan HIWIN guide rail + grinding rack

|

|

|

|

|||

|

Fixed mode

|

Vacuum absorb

|

|

|

|

|||

|

Precision

|

±0.01mm

|

|

|

|

|||

|

Cutting speed

|

0-1500mm/s(Set according to material)

|

|

|

|

|||

|

Cutting thickness

|

Standard cutting height: ≤45mm, customizable maximum cutting height 110mm

|

|

|

|

|||

|

Support file format

|

AI,PLT,DXF

|

|

|

|

|||

|

Rated power

|

11KW

|

|

|

|

|||

|

Rated voltage

|

380V±10%/220V±10% Optional

|

|

|

|

|||

|

Control System

|

Chinese English and Spanish LCD touch screen

|

|

|

|

|||

Recommended Tools

AMOR Automatic CNC Die Paper Corrugated Cutting Machine for Cartoon Box

AMOR digital cutting machine is widely used in the advertising printing and packaging industry. It is equipped with a replaceable tool head to meet the different cutting needs of customers cutting different materials. The cutting materials include various corrugated paper, Chevron board, car stickers, adhesive, Photo frame paper, KT board, gray board paper, honeycomb board, acrylic board, PVC board, foam, etc.

Multi-function cutting head design, highly integrated multi-group machining tools, interactive cutting, punching, and scribing in one working unit for one-stop operation. Oscillating knife cutting head, crimping reel, V-cutting head, and high-speed milling head. Can cut 30 or 60mm honeycomb paperboard, acrylic sheet, corrugated paper, plastic corrugated board, gray board paper, white cardboard, film, composite material, leather, cloth, rubber sheet, pearl cotton, aluminum composite board, and foam KT board A variety of materials. The V-cut system can cut V-shaped grooves of 5 different angles such as 45°, 30°, 22.5°, 15°, 0°, etc. Customers can choose the appropriate configuration according to their own needs.

Applications

Advantages of AMOR oscillating knife for cutting corrugated boxes:

AMOR carton oscillating knife cutting machine has 5 advantages:

1. Simultaneously complete a variety of carton processing processes:

AMOR carton numerical control vibrating knife cutting machine has stable mechanical performance and can be equipped with grooving cutters, oscillating cutters and creasing tools to meet the different technological needs of carton cutting, grooving and creasing.

2. High processing accuracy:

The high-performance cutter controller is equipped with high-quality Japanese Mitsubishi servo motors and precise drivers. Relying on stable cutting performance, low operating cost and intelligent production process, it ensures the rapid profitability of customers and realizes standard, fast, efficient and intelligent carton processing technology.

3. The processing method is more flexible:

without any molds, it can meet the processing of any carton style. Widely used in the design and proofing of packaging cartons, reducing design costs, shortening design time, and meeting customers’ production of multiple styles and small batch orders.

4. To meet the processing needs of a variety of materials:

corrugated cardboard, cardboard, honeycomb cardboard, foam board, plastic board, EVA, KT board and other packaging materials can be cut.

5. Intelligent cutting equipment helps customers improve their competitiveness:

AMOR carton numerical control vibrating knife cutting machine can improve your design technology, enhance design concepts, and help customers better complete the development of new styles, ahead of their peers.

Our Advantages

CNC Cardboard Cutting Machine for Cutting Creasing Grooving Corrugated Boxes Honeycomb Cardboard Cutting Machine

5.The machine bed is welded to ensure the accuracy and long life.

The square tube welding is integrated, high temperature heat treatment, milling machine finishing.

6.Using Taiwan HWIN brand guide rail and four rows of high-precision ball sliders

, with its own lubrication system, low friction resistance, to ensure high-speed and smooth cutting.

7.Scientific and reasonable wiring,

each wire has a serial number, which is convenient for maintenance of the machine. All electrical components are equipped with Schneider brand electrics as standard, and Siemens electrics with UL certification can also be selected according to customer requirements.

8.The machine beam adopts all-aluminum structure,

which reduces the weight of the beam and ensures the rapid movement of the machine. The mold extrusion process ensures the accuracy of the installation of the guide rail, the rack and the cutter head.

Certifications

Product Packaging

CNC Cardboard Cutting Machine for Cutting Creasing Grooving Corrugated Boxes Honeycomb Cardboard Cutting Machine

Hot Searches