- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.5-1.2mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Dixin

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

9000*1000*1200mm

-

Weight:

-

3500 kg

-

Feeding width:

-

as drawing

-

Marketing Type:

-

Hot Product

-

Product name:

-

Gutter Roll Forming Machine

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

Cutting type:

-

Automatic Hydraulic Cutting

-

After-sales Service Provided:

-

Engineers

-

Color of Machine:

-

Customer's Requiremennt

-

Advantage:

-

Excellent Performance

-

Main frame:

-

350H Steel

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.5-1.2mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Dixin

-

Voltage:

-

380v 50Hz

-

Dimension(L*W*H):

-

9000*1000*1200mm

-

Weight:

-

3500 kg

-

Feeding width:

-

as drawing

-

Marketing Type:

-

Hot Product

-

Product name:

-

Gutter Roll Forming Machine

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Control system:

-

PLC(imported Brand)

-

Cutting type:

-

Automatic Hydraulic Cutting

-

After-sales Service Provided:

-

Engineers

-

Color of Machine:

-

Customer's Requiremennt

-

Advantage:

-

Excellent Performance

-

Main frame:

-

350H Steel

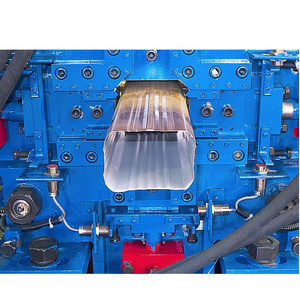

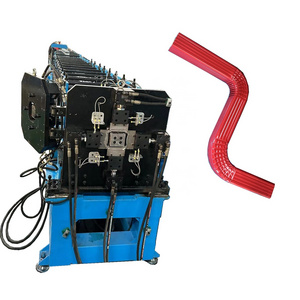

Roof Rain Gutter Roll Forming Machinery Downspout Gutter Forming Machine Water Gutter Channel Making Machine

Our advantages:

High Efficiency

Low Energy Consumption

Automatic & Easy Operate

Excellent Service

Long Life Machine

Gutter Machine Panel Drawing: ( Send us your panel drawing, we can customize according to your requirement)

Product Pictures:

Send us your drawing , we can customize for you !!!

|

Product Name |

Water Rain Gutter Roll Forming Machine |

|

1.Suitable material |

Color steel sheet , galvanized steel sheet,aluminum sheet |

|

2.Installation Dimension (L*W*H): |

9 m*1.1m*1. 2 m |

|

3.Main motor power |

5.5KW with Cycloidal reducer |

|

4.Hydraulic station power |

4KW |

|

5. Hydraulic oil pump |

CB-E 310 |

|

6.Thickness of material |

0.5mm~1.2mm |

|

7.Diameter of principal axis |

Φ70-90mm |

|

8.Material expand width |

as drawing |

|

9.Electric tension |

380V 3phase 50HZ or as the customer's requirements |

|

10.Material of roller |

High grade 45# forged steel plated with hard chrome plating |

|

11.Controlling system |

PLC |

|

12.Processing speed |

10- 1 5m/min |

|

13.Processing precision within |

1.00mm (depend on design) |

|

14.Material of cutting blade |

Cr12 mould steel with quenched treatment |

|

15.Kind of drive |

0.6 inch chain link bearing model 6210 |

|

16.Roller station |

16-20 Rollers as drawing |

|

17.Roller material |

high grade 45#steel; Cr12 quenching |

|

18. Leak frame load-bearing |

2 T |