- Product Details

- {{item.text}}

Quick Details

-

Power:

-

29KW

-

Dimension(L*W*H):

-

10914mm*1190mm*1711mm

-

Weight:

-

3000 KG

-

Output product name:

-

puff pastry

-

Marketing Type:

-

Hot Product 2023

-

Warranty of core components:

-

negotiable

-

Application:

-

Food Industry

-

Capacity:

-

1T/h

-

Accessories:

-

Import siemens,mitsubishi etc.

-

Operating procedure:

-

Panasonic PLC

-

Advantage:

-

Easy Operation High Performance

-

shape:

-

long strip

-

Pre-sales consultation:

-

Guided site selection & installation service

-

After-sales service:

-

Engineer online support and on-site service

-

Package:

-

Wooden box

Quick Details

-

Brand Name:

-

Juheng

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

29KW

-

Dimension(L*W*H):

-

10914mm*1190mm*1711mm

-

Weight:

-

3000 KG

-

Output product name:

-

puff pastry

-

Marketing Type:

-

Hot Product 2023

-

Warranty of core components:

-

negotiable

-

Application:

-

Food Industry

-

Capacity:

-

1T/h

-

Accessories:

-

Import siemens,mitsubishi etc.

-

Operating procedure:

-

Panasonic PLC

-

Advantage:

-

Easy Operation High Performance

-

shape:

-

long strip

-

Pre-sales consultation:

-

Guided site selection & installation service

-

After-sales service:

-

Engineer online support and on-site service

-

Package:

-

Wooden box

Product Display

Introduction

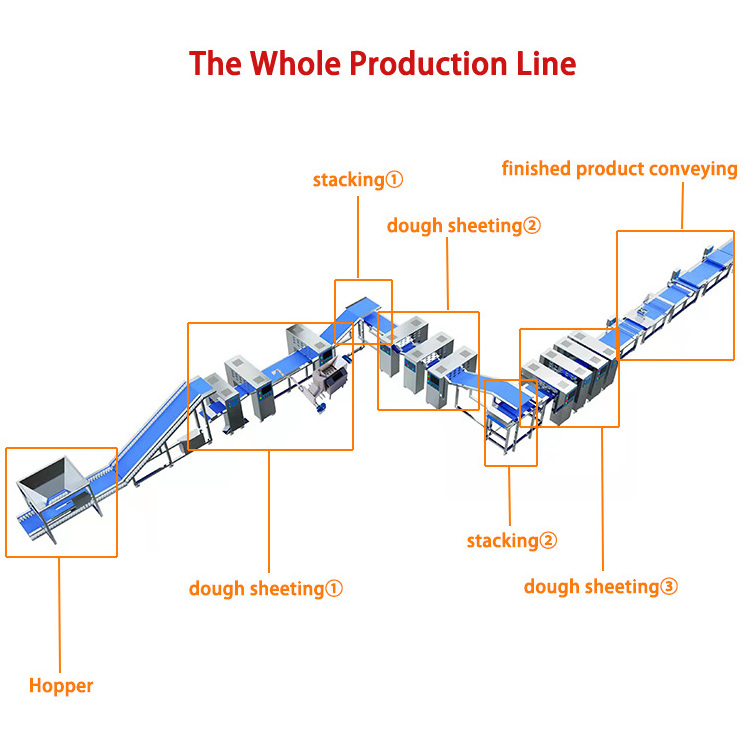

①The Fully Automatic Puff Pastry Dough Sheets Production Line processes are:

1) Kneading dough.

2) The divider divides the dough bulk.

3) The dough dough is

preliminarily processed,and the surface becomes smooth and the thickness becomes

uniform.

4) The continuous thinning mechanism further processes the dough.

5) The

butter injection mechanism squeezes the butter evenly in the middle of the dough

sheet.

6) The folding mechanism folds the dough to wrap the butter.

7) The thinning

mechanism presses the dough and butter tightly and further rolls the dough thinner.

8) The stacking mechanism stacks the dough layer by layer and the layers of puff pastry

appear. Customers can control the number of puff pastry layers by adjusting the speed.

9) Repeat the steps of stacking and thinning.

10)The pressing mechanism will carry out

the final rolling.

11) The puff pastry with rich layers is finished.

②The equipment includes two sets of stacking devices,and the layers of puff pastry can

generally reach 72 layers, of course the specific number of layers can be adjusted.

③With the fully automatic proecesses,the Puff Pastry Production/Lamination Line

achieves the most efficient pastry production.

At the end of puff pastry production line,

we can configure different shaping unit to it, such as croissant shaping unitegg tart

shaping unit and other products made with puff pastry.

This production line is very

suitable for customers with relatively high output. Of course we also have targeted

solutions for customers with small businesses.

*We accept customization, please tell us your needs, such as output, bread size, etc., the

more detailed the better. We will do our best to provide you with a satisfactory solution.

Details Images

Hot Searches