- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZTRFM

-

Voltage:

-

cuztomized

-

Power:

-

8kw

-

Dimension(L*W*H):

-

11800mm*12000mm*9000mm

-

Weight:

-

5500 kg

-

Certification:

-

CE , ISO9001

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Main motor power:

-

8kw

-

material:

-

color steel coil

-

Material thickness:

-

0.5-0.7 mm

-

Drive mode:

-

single Chain transmission

-

Shaft material:

-

no.45 forge steel and quenched

-

Working speed:

-

10m--15m/min

Quick Details

-

Pipe Material:

-

Iron

-

Production Capacity:

-

10m-15m/min

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZTRFM

-

Voltage:

-

cuztomized

-

Power:

-

8kw

-

Dimension(L*W*H):

-

11800mm*12000mm*9000mm

-

Weight:

-

5500 kg

-

Certification:

-

CE , ISO9001

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Main motor power:

-

8kw

-

material:

-

color steel coil

-

Material thickness:

-

0.5-0.7 mm

-

Drive mode:

-

single Chain transmission

-

Shaft material:

-

no.45 forge steel and quenched

-

Working speed:

-

10m--15m/min

downspout roll forming machine and elbow machine

picture of Manual uncoiler

Manual uncoiler

|

No. |

Manual decoiler parameters |

|

|

1 |

Loading Capacity |

3 T |

|

2 |

Expanding inner diameter |

450-550mm

|

|

3 |

Feeding width |

Max 500mm |

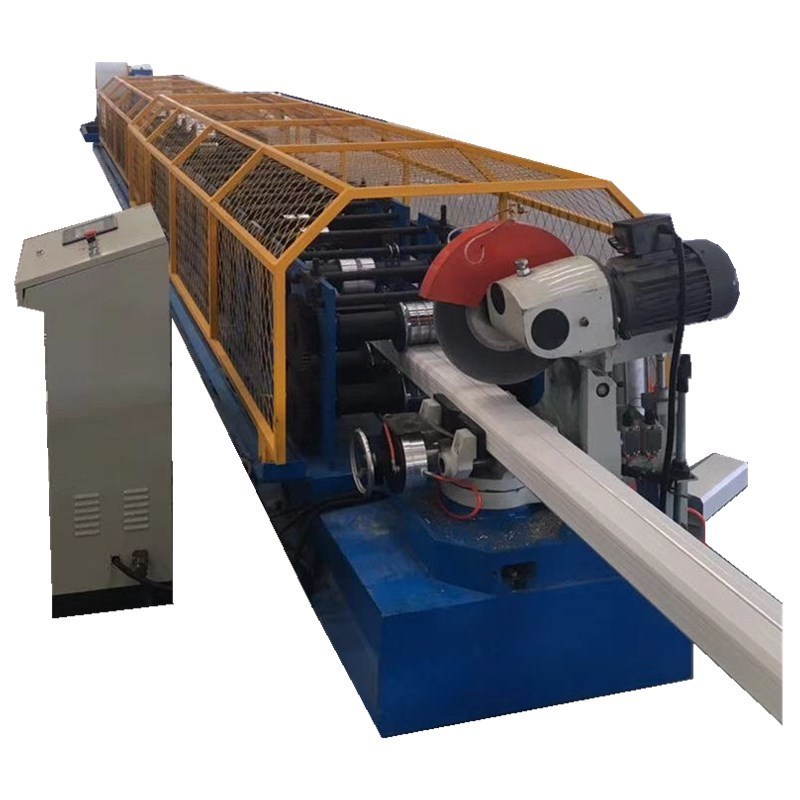

picture of

Main roll forming machine

Main roll forming system

| No. | Main roll forming system parameters | |

| 1 | Main motor power | 8kw |

| 2 | material | color steel coil |

| 3 | Material thickness | 0.5-0.7 mm |

| 4 | Drive mode | Single Chain transmission |

| 5 | Main shaft diameter | 60mm |

| 6 | Roller material | no.45 forge steel and quenched chrome coated 0.05mm |

| 7 | Shaft material | no.45 forge steel and quenched |

| 8 | Roll station | 23 groups |

| 9 | Working speed | 10m--15m/min(Exclude cutting time) |

| 10 | Weight of main roll forming machine | Weight of main roll forming machine |

| 11 | Size of machine | About 11800×12000×9000mm (L x W x H) |

| 12 | Color | depend on customer |

| 13 | Coder | Omron |

| 14 | Control | PLC Panasonic |

| 15 | Voltage | 380V/ 50HZ /3Phase |

| 16 | Computer operating panel | touching screen |

| 17 | Cutting tolerance | ± 2mm |

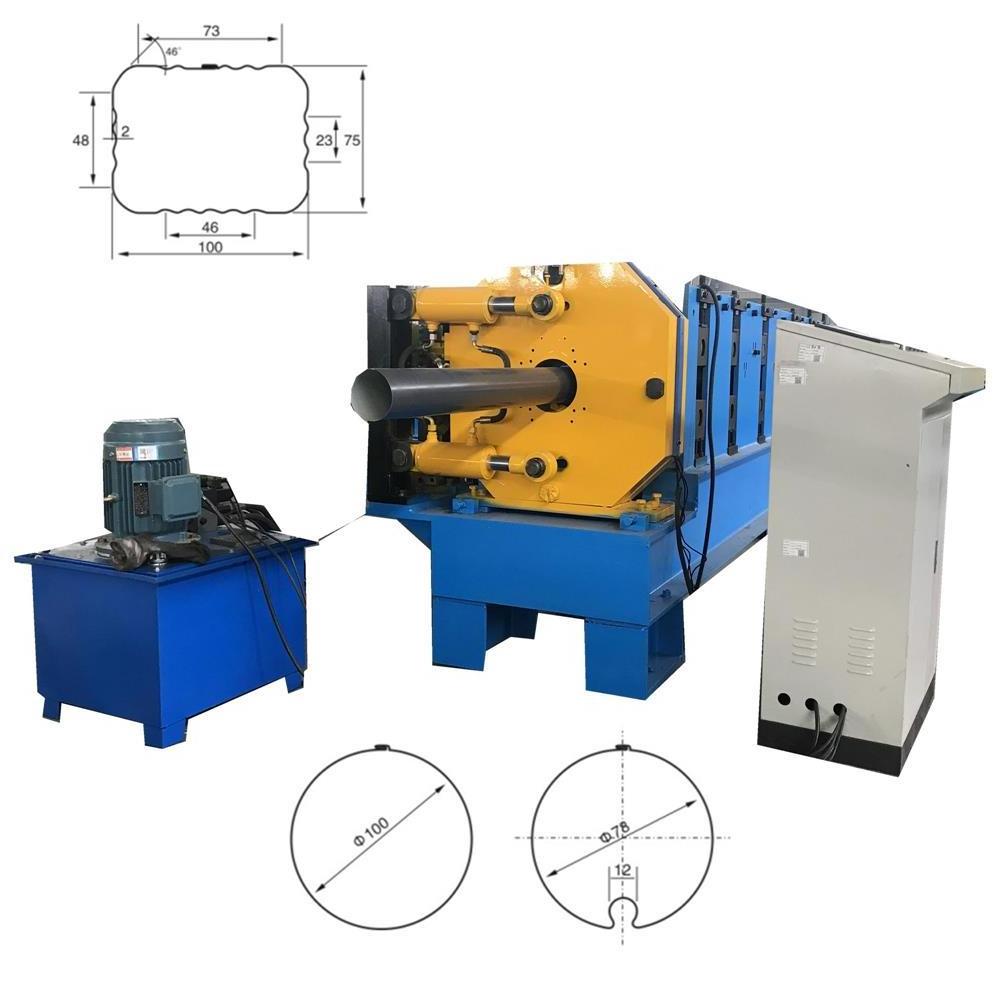

picture of elbow machine

Corner Bead V Keel, Angle Iron Bending Machine

A. Specification of Elbow machine

1) Function : curving the pipe and locking mouth

2) Motor power: 4KW

3) Control method : Electrical control

4) Max angle: 90 degree

5) Dimension of the machine: 1300 mm×650 mm×1500 mm

Cangzhou ZHONGTUO is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of building. It is located in northwest of CangZhou, as a long history of cold roll formingmachine production base. All products comply with international quality standards and greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe,South America, and Australia etc.

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

7. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing How to make machines much more automatic, accurate and high quality. We can make sure thatour machine could use more than 20 years without any problem. We can provide 2 years free qualityassurance.

8. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without 45 working days. If you need machines in a hurry, we can make it for you less than a month.

Click on the pictures, and learn more: