- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

No

-

Particle:

-

0.6/0.8/1.2/1.5

-

Product name:

-

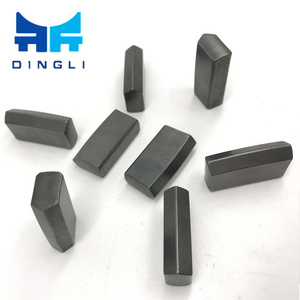

Wearing Outlet slag wear sleeve Parts for decanter centrifuge

-

Application:

-

Replacing Parts for horizontal screw decanter centrifuge

-

Material:

-

100% Virgin Tungsten Carbide

-

Grade:

-

YG6 YG8 K10 K20

-

Surface:

-

Ground

-

Size:

-

OEM Accepted

-

Keywords:

-

Tungsten Carbide Wear Plate

-

Advantage:

-

Excellent Wear Resistance

-

Shape:

-

OEM

-

MOQ:

-

Sample and 300PCS

Quick Details

-

Alloy Specification:

-

YG/YN/TN/WZ/

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

No

-

Model Number:

-

No

-

Particle:

-

0.6/0.8/1.2/1.5

-

Product name:

-

Wearing Outlet slag wear sleeve Parts for decanter centrifuge

-

Application:

-

Replacing Parts for horizontal screw decanter centrifuge

-

Material:

-

100% Virgin Tungsten Carbide

-

Grade:

-

YG6 YG8 K10 K20

-

Surface:

-

Ground

-

Size:

-

OEM Accepted

-

Keywords:

-

Tungsten Carbide Wear Plate

-

Advantage:

-

Excellent Wear Resistance

-

Shape:

-

OEM

-

MOQ:

-

Sample and 300PCS

Product Description

We mainly provide special, professional, high-performance hard alloy: hard alloy ring for mechanical seal and pump shaft sleeve; Hard alloy for oil and natural gas wellhead installation (valve core, valve seat, anti-wear sleeve, hole plate, fixed hole plate); All kinds of threaded nozzles and hemispheres for SP alloy drill bits; Balls and seats for liquid elevators; Carbide bar and plate; Non-magnetic carbide; All kinds of hard alloy mold; Carbide props and rotary machines; The manufacture of hard alloy for geological mining and special-shaped wear-resistant parts for other fields.

OEM Accepted!!! Pls Provide Your Drawings!

Alloy Grade

|

Grade

|

Component(%)

|

|

|

Density

(g/cm3)

|

HRA

|

Bending resistance(>N/mm2)

|

Mean Size(pm)

|

Grain Size(pm)

|

||

|

|

Co

|

Dopant

|

Balance

|

|

|

|

|

|

||

|

YG6

|

5.8-6.3

|

/

|

WC

|

14.6-15.0

|

89.5-91

|

1800

|

1.2

|

0.8-2.0

|

||

|

YG6X

|

5.8-6.3

|

0.5

|

WC

|

14.4-14.7

|

90.5-91.5

|

1650

|

0.8

|

0.6-1.0

|

||

|

YG8

|

7.5-8.2

|

|

WC

|

14.4-14.7

|

89.0-90.5

|

2200

|

1.2

|

1.0-1.5

|

||

|

YG11

|

11.0-11.5

|

|

WC

|

14.2-14.4

|

87.0-88.5

|

2800

|

1.2

|

1.0-2.0

|

||

|

YG11C

|

11.0-11.5

|

|

WC

|

14.2-14.4

|

86.0-88.0

|

3000

|

1.5

|

1.0-2.5

|

||

|

YG15

|

14.5-15

|

|

WC

|

13.9-14.0

|

86.0-88.0

|

3300

|

1.2

|

1.0-2.0

|

||

|

YG20

|

20.0-20.5

|

|

WC

|

13.2-13.5

|

84.0-85.0

|

3400

|

1.2

|

1.0-2.0

|

||

|

K05VF

|

4.5-5.0

|

0.6

|

WC

|

14.6-15.0

|

92.5-93.0

|

1500

|

0.6

|

0.6-1.0

|

||

|

K10VF

|

5.5-6.2

|

0.6

|

WC

|

14.5-14.7

|

91.5-92.5

|

1550

|

0.6

|

0.6-1.0

|

||

|

K20VF

|

7.5-8.0

|

0.6

|

WC

|

14.5-14.7

|

90.5-91.5

|

1800

|

0.6

|

0.6-1.0

|

||

|

...

|

|

|

|

|

|

|

|

|

||

Test items: density, Rockwell hardness, transverse fracture strength, metallographic

Inspection basis: GB/T3850-2015 Density determination method for dense sintered metal materials and cemented carbide

GB/T3949.1-2015 Cemented Carbide Rockwell Hardness Test (Scale A) Part 1: Test Method

GB/T3851-2015 Cemented Carbide - Determination of Transverse Fracture Strength

GB/T3489-2015 Cemented carbide - Metallographic determination of porosity and non-combined carbon

GB/T3488.1-2014 Cemented Carbide - Metallographic Determination of Microstructure - Part 1: Metallographic Photographs and Description

Main inspection equipment: BS224S density balance, 574R Rockwell hardness tester, DMI5000M metallographic microscope, CMT5305 material testing machine

Test results:

Test time:Nov. 18 2021

|

Test items

|

YG6

|

YN6

|

YG8

|

YG15

|

|

Density (g/cm3)

|

14.98

|

14.88

|

14.72

|

14.09

|

|

Rockwell Hardness (HRA)

|

90.8

|

90.6

|

89.5

|

85.8

|

|

Transverse breaking strength (N/mm2)

|

1810

|

1860

|

2110

|

2620

|

|

Porosity

|

A02B00

|

A02B00

|

A02B00

|

A02B00

|

|

non-combined carbon

|

C00

|

C00

|

C00

|

C00

|

|

Holes (pcs/cm2)

|

No

|

No

|

No

|

No

|

|

Average grain size of WC phase (μm)

|

Fine grain

|

Fine grain

|

Fine grain

|

Medium grain

|

Feature

1. More Accurate Slot Opening, Polishing, And Smooth Surface

2. High Stability and Pressure Loading, Corrosive Resistance

3. Smooth Surface hence Low Resistance

4. Longer Use Life

5. Easy to install

6. Customized According to Drawing

2. High Stability and Pressure Loading, Corrosive Resistance

3. Smooth Surface hence Low Resistance

4. Longer Use Life

5. Easy to install

6. Customized According to Drawing

Detailed Images

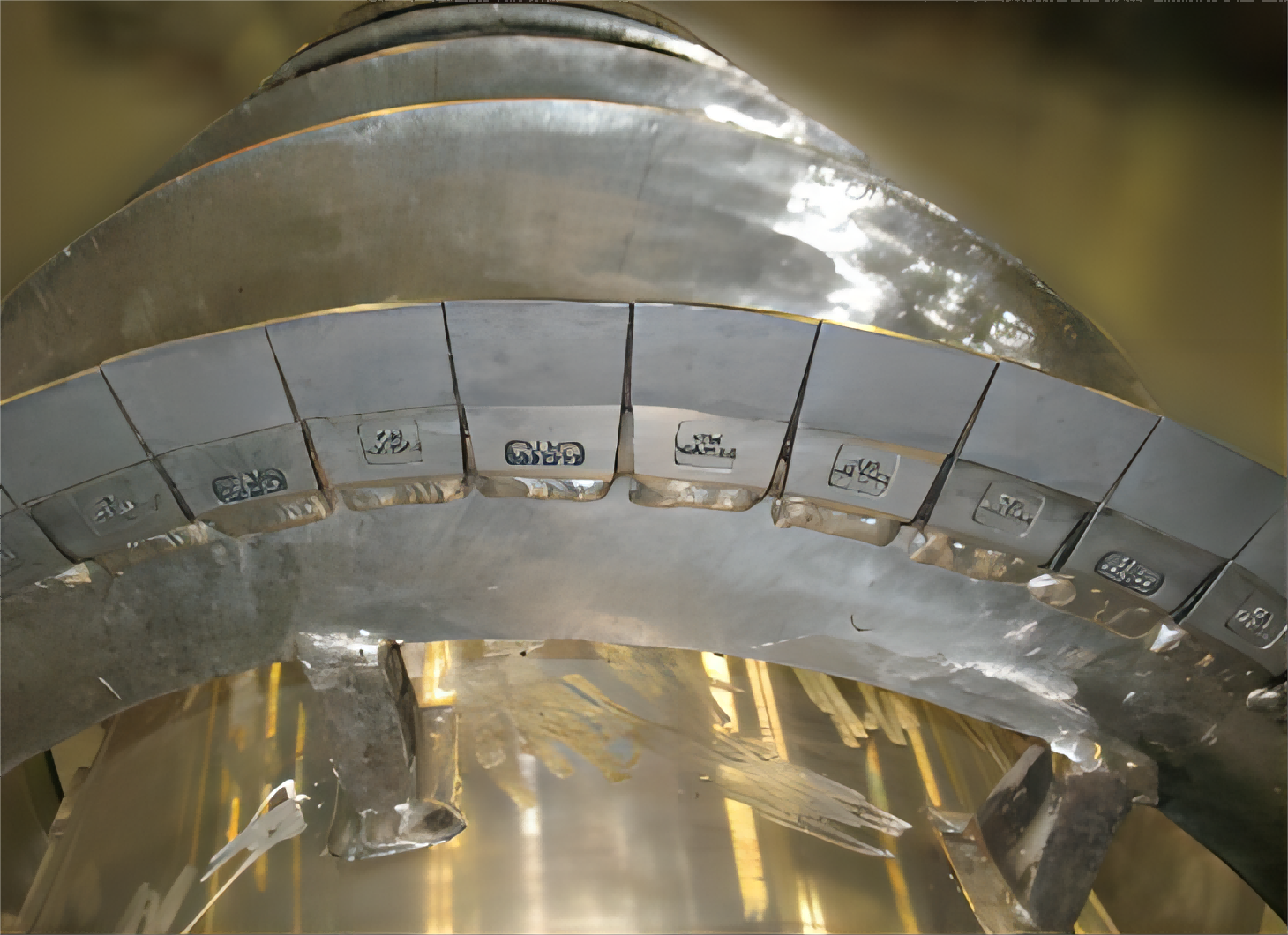

Tungsten Carbide Tiles

Spare parts are widely used for the separation equipment, such as decanter centrifuge, disc stack separator, etc.

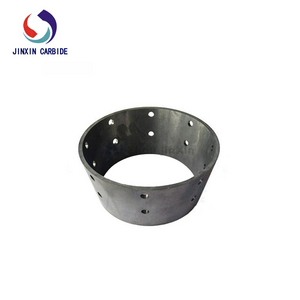

Carbide Sleeve Bushing

Suitable for pumps, oil pumps and mud pumps.

Carbide Valve Parts for Fluid Control

Used in oil and natural gas fluid control pumps.

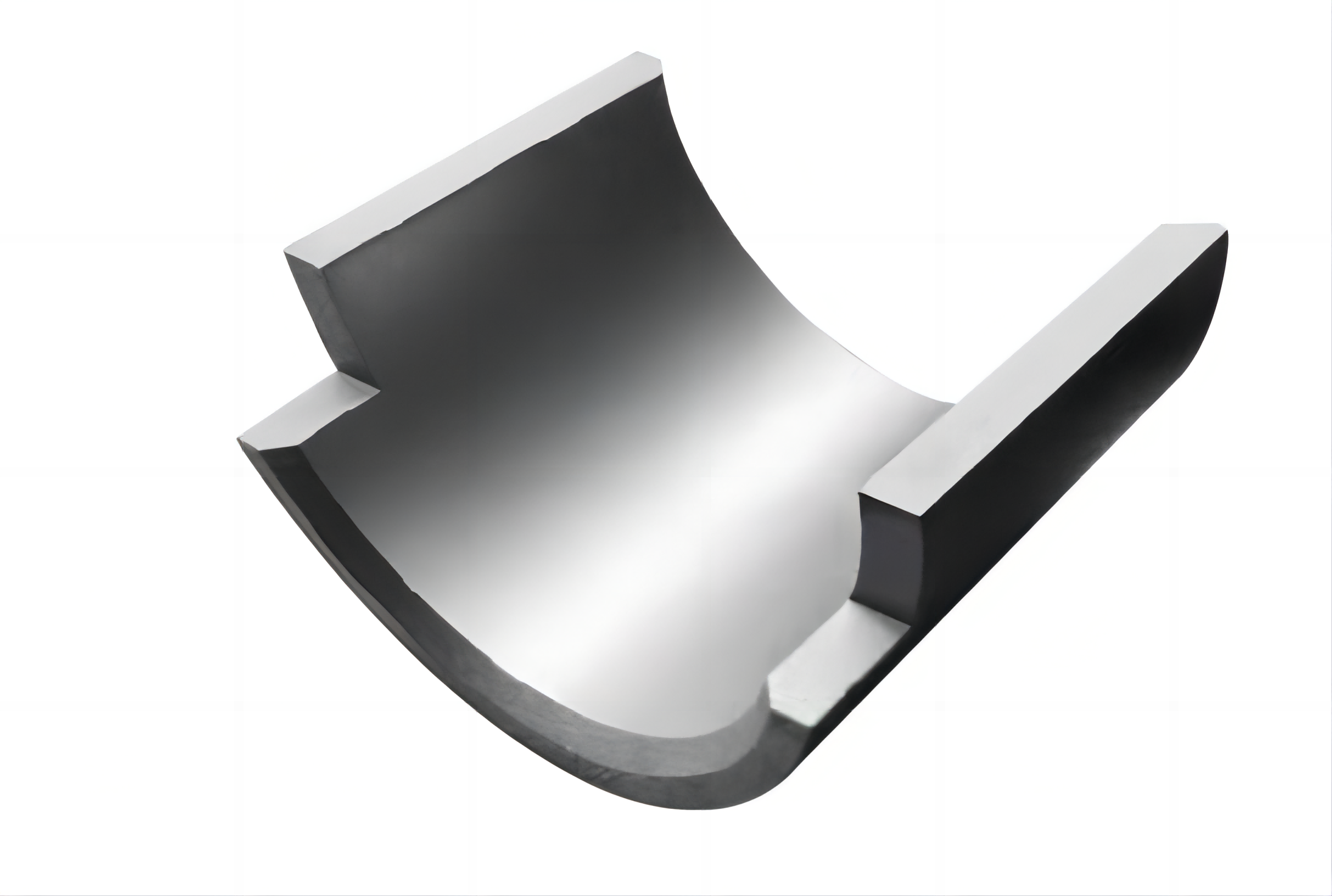

Carbide Ball and Seat

Mainly used to separate

sludge and oil.

sludge and oil.

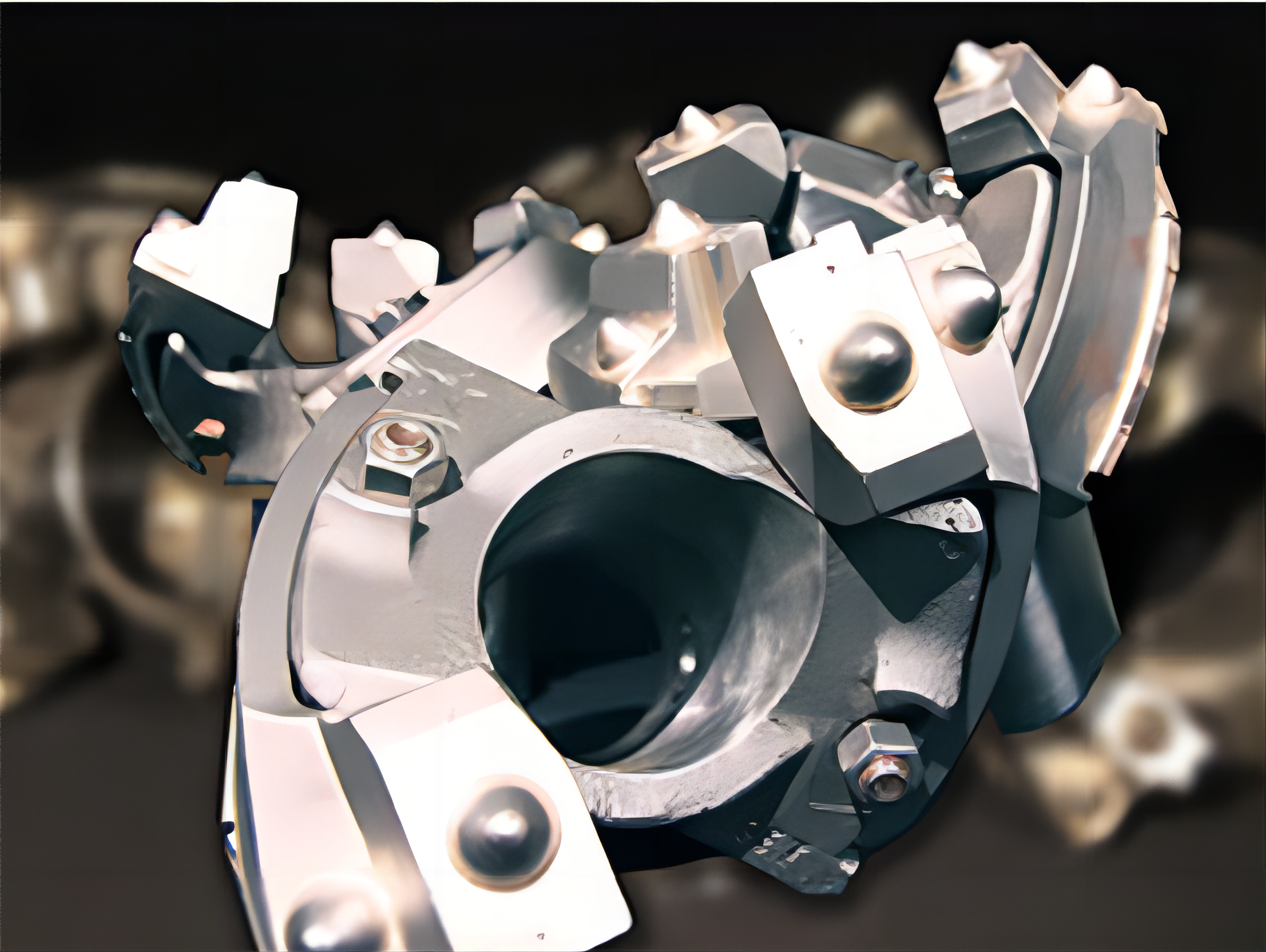

Carbide Tooth

Used in the mining, oily sludge and drilling mud industry.

Carbide Mud Nozzle

Used in the

petroleum industry

Carbide Mud Nozzle

Used in the petroleum industry

Hot Searches