- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

AC380V50Hz

-

Dimension(L*W*H):

-

1070*710*1970mm

-

Weight (KG):

-

600

-

Power (kW):

-

3.5

-

Product name:

-

DS703A Controller Small Hole High Speed Drilling Micro EDM Machine

-

Machine type:

-

Drilling Equipment

-

Work Table Size:

-

400*300mm

-

Work Table Travel:

-

250*200mm

-

servo travel:

-

330mm

-

spindle travel:

-

200mm

-

Electrode diameter:

-

Dia 0.3--3mm

-

Max. working current:

-

22A

-

Function:

-

High Speed Drilling

-

Application:

-

Small Hole

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Year:

-

2023

-

Brand Name:

-

jzsk

-

Voltage:

-

AC380V50Hz

-

Dimension(L*W*H):

-

1070*710*1970mm

-

Weight (KG):

-

600

-

Power (kW):

-

3.5

-

Product name:

-

DS703A Controller Small Hole High Speed Drilling Micro EDM Machine

-

Machine type:

-

Drilling Equipment

-

Work Table Size:

-

400*300mm

-

Work Table Travel:

-

250*200mm

-

servo travel:

-

330mm

-

spindle travel:

-

200mm

-

Electrode diameter:

-

Dia 0.3--3mm

-

Max. working current:

-

22A

-

Function:

-

High Speed Drilling

-

Application:

-

Small Hole

Products Description

|

Item

|

DS703A

|

|

Worktable Size

|

400*300mm

|

|

Worktable Travel

|

250*200mm

|

|

Servo Travel

|

330mm

|

|

Spindle Travel

|

200mm

|

|

Electrode Diameter

|

0.3 - 3mm

|

|

Max. Working Current

|

22A

|

|

Power Input

|

380V/50Hz 3.5kW

|

|

Machine Weight

|

600kg

|

|

Overall Dimension

|

1070m*710m*1970mm

|

|

Homepage

|

|

|

Price

|

Introduction

1. The mechanical part is mainly composed of the coordinate worktable, spindle head, swivel head, column and machine tool body.

2. The electric cabinet is fixed in the machine tool body, including the pulse power supply, the principal axis servo system and the machine tool electric-appliances.

3. The operating fluid system includes the high-pressure pump and the operating fluid container, which are located at the side of machine tool body.

4. Using pure water or tap water as the working fluid.

5. The X-axis and Y-axis of the worktable are equipped with digital device.

6. It can penetrate the slant face and curved surface of the workpiece to process directly.

7. The largest depth-diameter-ratio of the hole can be over 200:1.

Usage

1. Used for processing deep and small size hole in many kind of conductive materials like stainless steel, hardened steel,

carbide, copper, aluminum.

2. Used for silk hole in WEDM, spinneret hole in spinning jet and plate, group holes in filter board and sieve plate, cooling

holes in motor blades and cylinder body, oil and gas channel hole of hydraulic and pneumatic valve.

3. Used for removing aiguille and screw tap of workpiece without damaging the original hole or threads.

2. The electric cabinet is fixed in the machine tool body, including the pulse power supply, the principal axis servo system and the machine tool electric-appliances.

3. The operating fluid system includes the high-pressure pump and the operating fluid container, which are located at the side of machine tool body.

4. Using pure water or tap water as the working fluid.

5. The X-axis and Y-axis of the worktable are equipped with digital device.

6. It can penetrate the slant face and curved surface of the workpiece to process directly.

7. The largest depth-diameter-ratio of the hole can be over 200:1.

Usage

1. Used for processing deep and small size hole in many kind of conductive materials like stainless steel, hardened steel,

carbide, copper, aluminum.

2. Used for silk hole in WEDM, spinneret hole in spinning jet and plate, group holes in filter board and sieve plate, cooling

holes in motor blades and cylinder body, oil and gas channel hole of hydraulic and pneumatic valve.

3. Used for removing aiguille and screw tap of workpiece without damaging the original hole or threads.

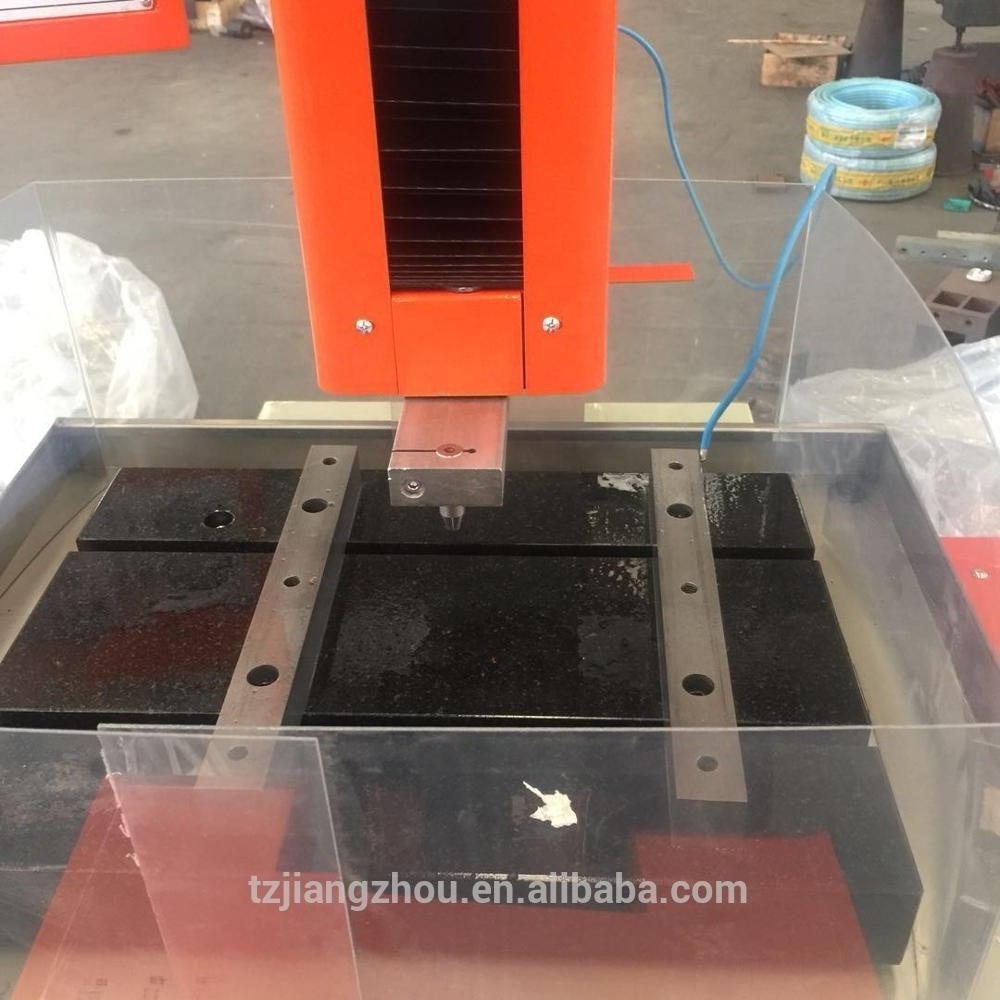

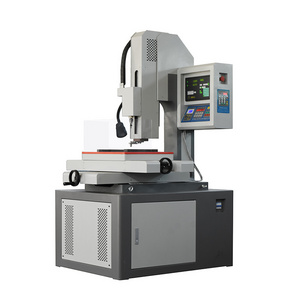

Product Display

Warranty period: one year

During warranty period, if you have any parts broken because of qulity problem, we will supply to you free of charge by express.

Out of warranty period, if you have any question, you can contact with us, we will supply our best service to you as usual.

1.Technical support online service provided .

2.Technical files service provided.

3.Machine operation video provided

4.On-site training service provided.

5.Spare parts replacement and repair service provided.

6.All of the questions will be replied within 24 hours

During warranty period, if you have any parts broken because of qulity problem, we will supply to you free of charge by express.

Out of warranty period, if you have any question, you can contact with us, we will supply our best service to you as usual.

1.Technical support online service provided .

2.Technical files service provided.

3.Machine operation video provided

4.On-site training service provided.

5.Spare parts replacement and repair service provided.

6.All of the questions will be replied within 24 hours

Main Products

Hot Searches