- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/customized

-

Dimension(L*W*H):

-

1350*880*1700mm

-

Power (kW):

-

15kw

-

Weight (KG):

-

400 KG

-

Name:

-

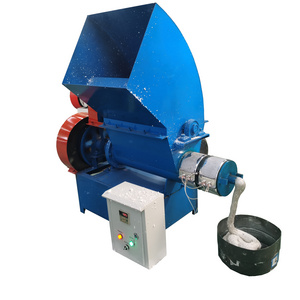

Waste foam plastic melting machine

-

Capacity:

-

300-600kg/h

-

Application:

-

Eps Foam box

-

Size of feeder:

-

600*400mm

-

Screw number:

-

double screw

-

Usage:

-

waste foam,EPS, XPS, EPP, EPE, PU,PVC etc.

-

keyword:

-

foam plastic board hot melter

-

Package:

-

wooden case

-

Material:

-

carbon steel

-

Marketing Type:

-

Hot Product 2019

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HS

-

Machine Type:

-

Waste foam plastic melting machine

-

Voltage:

-

380v/customized

-

Dimension(L*W*H):

-

1350*880*1700mm

-

Power (kW):

-

15kw

-

Weight (KG):

-

400 KG

-

Name:

-

Waste foam plastic melting machine

-

Capacity:

-

300-600kg/h

-

Application:

-

Eps Foam box

-

Size of feeder:

-

600*400mm

-

Screw number:

-

double screw

-

Usage:

-

waste foam,EPS, XPS, EPP, EPE, PU,PVC etc.

-

keyword:

-

foam plastic board hot melter

-

Package:

-

wooden case

-

Material:

-

carbon steel

-

Marketing Type:

-

Hot Product 2019

Product Description

Foam plastic board hot melter

Waste foam plastic melting machine

is also called foam blocks forming machine.It crusher waste foam, such as foam lunch box,cake box,packaging foam material, insulation material and a foaming material,Omentum white pollution garbage ,then heating screw plasticizing and extruding into lump.Make it more convenient transportation and sales.Split foam building block machine in the form of horizontal, shredders and melting machine to separate, operation placed the

shredder on the ground, holding a broom to sweep in material, grinding after the mill fan blowing directly

to host the hopper, so that not only saves the manpower and while avoiding the risk of artificial direct

operation.Widely used for Waste foam such as EPS, XPS, EPP, EPE, PU, PVC,etc.

Technical parameter

|

Model

|

Power

|

Capacity

|

Dimesnion(mm)

|

Weight

|

|

HS-220

|

15kw

|

300kg/h

|

1350*880*1700

|

400kg

|

|

HS-245

|

18.5kw

|

400kg/h

|

1450*950*1500

|

500kg

|

Detailed Images

Features

1. All recycled materials can be produced after being classified, crushed and cleaned without drying.Both of wet or dry materials are available.

2. From raw material crushing, cleaning, feeding to pelleting are automated.

3. Adopt high-pressure friction uninterrupted heating system and automatic heating production, so that avoiding continuous heating and energy saving.

4. Adopt split automatic power distribution system to ensure safe and normal operation of the motor.

5. The screw barrels are made of imported high-strength high-quality carbon structural steel, which is durable.

6. The mould is made of high-quality carbon.Never leaking.Adopt heating with internal heating rod and fully used,thus can save 20% electricity.

7. This machine has features of large output, high efficiency, low dust, low noise, low energy consumption, convenient operation and low maintenance cost.

Application

Sush as waste foam,eps insulation board,pearal cotton,etc

Packing & Delivery

Package

*

For the small machine,they will packaged into standard wooden case

*For the large quantity and large machine,we will load it into 20ft container or 40ft container

Delivery

*

Delivery by sea

*Delivery by express

*Delivery to your agents' warehouse in China,then will offer you tracking number

Hot Searches