- Product Details

- {{item.text}}

Quick Details

-

Brand:

-

chuanzuan

-

size:

-

8 1/2 inch 215.9mm

-

Application:

-

well drilling

-

Weight:

-

45kg

-

IADC CODE:

-

537

-

COLOUR:

-

Required

-

Certification:

-

CE, API

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

chuanzuan

-

Name:

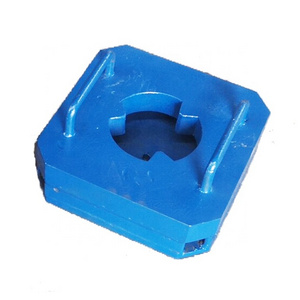

-

roller cutter

-

Brand:

-

chuanzuan

-

size:

-

8 1/2 inch 215.9mm

-

Application:

-

well drilling

-

Weight:

-

45kg

-

IADC CODE:

-

537

-

COLOUR:

-

Required

-

Certification:

-

CE, API

| Commodity | Size | IADC | WOB(Weight On Bit) | RPM | Formation |

|

9 5/8inch 244.5mm |

537 |

0.50~1.05KN |

110~40 | Low compressive strength, medium hard formation with hard abrasive interlayer, like Hard shale, anhydrite, soft limestone, sandstone, dolomite with mezzanine, etc. |

1)Cutting Structure

The wear-resisitance of the teethy is enhanced with premium tungsten carbide hardfacing on the tooth surfaces for the steel tooth bit. The durability of premium tngsten carbide inserts is improved with new formulas and new techniques for insert bit.

2)Gauge Structure

Multipe gauge protection with gauge trimmers on the heel of cone, tungsten carbides insert and hardfacing on the shirt tail increases gauge holding capability and bearing life.

3)Bearing structure

High precisiong journal bearing with two thrust faces.Balls lock the cone. Hardfaced head bearing surface. Cone bearing inlaid with friction-reducing alloy and then silver plated. abrasion resistance and seizure resistance of the bearing are improved.

4)Seal and Lubrication

Premium HNBR O-ting, optimal seal compression and curved seal strcture can enhance seal performance. The pressure compensat or system and adwanced grease can greatly increase the lubricating reliability.

5)Product Application

It can receive high WOB in the conwentional drilling. Ti is suitable for various formations by matcing cutting structure with defferent tooth shape, tooth density and tooth exposure height.

We also provide othe r types

| IADC | Applicable formation | WOB(KN/mm) | PRM(R/min) |

| 415/425/435 | Low compressive strength, high drill-ability and extremely soft formation, like shale, clay, sandstone, conglomerate etc. | 0.35~0.90 | 140~70 |

| 447 | Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, plaster etc. | 0.35~100 | 140~60 |

| 517 | Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, etc | 0.37~1.05 | 120~50 |

| 527 | Soft formation with low compressive, like Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, anhydrite etc. | 0.37~1.05 | 120~50 |

| 537/547 | Low compressive strength, medium hard formation with hard abrasive interlayer, like Hard shale, anhydrite, soft limestone, sandstone, dolomite with mezzanine, etc. | 0.50~1.05 | 110~40 |

| 617/627 | High compressive strength, medium hard and thick hard interlayer, like hard shale, limestone, sandstone, dolomite, etc. | 0.50~1.05 | 80~40 |

| 637/647 | High compressive strength, medium hard and high abrasive formation, like limestone, dolomite, sandstone, chert, etc. | 0.7~1.20 | 70~40 |

How to choose the right drill bit for yourself?

Soft formation TCI tricone bits:

The soft formation TCI tricone bits are used to drill low compressive strength, very soft formations. This bit maximized to use of both conical and chisel tungsten carbide inserts of large diameters and high projection. This cutting structure design, combined with maximum cone offset, results in high bit penetration rates. The deep intermesh of cutter rows prevents bit bailing in sticky formations.

Medium formation TCI tricone bits:

The medium formation TCI tricone bits features aggressive chisel tungsten carbide inserts on the heel rows and inner rows. This design provides a fast drilling rate and added cutting structure durability in medium to medium hard for mations. The HSN rubber O-ring provides adequate sealing for bearing durability.

Hard formation

TCI tricone bits

:

The hard formation TCI tricone bits can be used to drill hard and abrasive formations. Wear resistance tungsten carbide inserts are used in the outer rows to prevent loss of bit gauge. Maximum numbers of hemispherical shaped inserts are used in all rows to provide cutter durability and long life.