- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

GU-500SD-400

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

Good Use

-

Model Number:

-

GU-500SD

-

Type:

-

Two components cartridge

-

Item No:

-

GU-500SD

-

Mixing ratio:

-

3:1

-

Available capacity:

-

400/585ml

-

Shelf life:

-

18 months

-

Mixing color:

-

Orange

-

Applications:

-

Water and winter season

-

Feature:

-

Heavy loading and bonding

-

Advantage:

-

Anchoring without expansion pressure

-

Working time:

-

Slow curing

-

Brand:

-

Good Use or customized

Quick Details

-

CAS No.:

-

Mixcure

-

Other Names:

-

Injection epoxy adhesive

-

MF:

-

Mixture

-

EINECS No.:

-

GU-500SD-400

-

Place of Origin:

-

Taiwan, China

-

Brand Name:

-

Good Use

-

Model Number:

-

GU-500SD

-

Type:

-

Two components cartridge

-

Item No:

-

GU-500SD

-

Mixing ratio:

-

3:1

-

Available capacity:

-

400/585ml

-

Shelf life:

-

18 months

-

Mixing color:

-

Orange

-

Applications:

-

Water and winter season

-

Feature:

-

Heavy loading and bonding

-

Advantage:

-

Anchoring without expansion pressure

-

Working time:

-

Slow curing

-

Brand:

-

Good Use or customized

High bonding injection epoxy adhesive for fixing in wet concrete

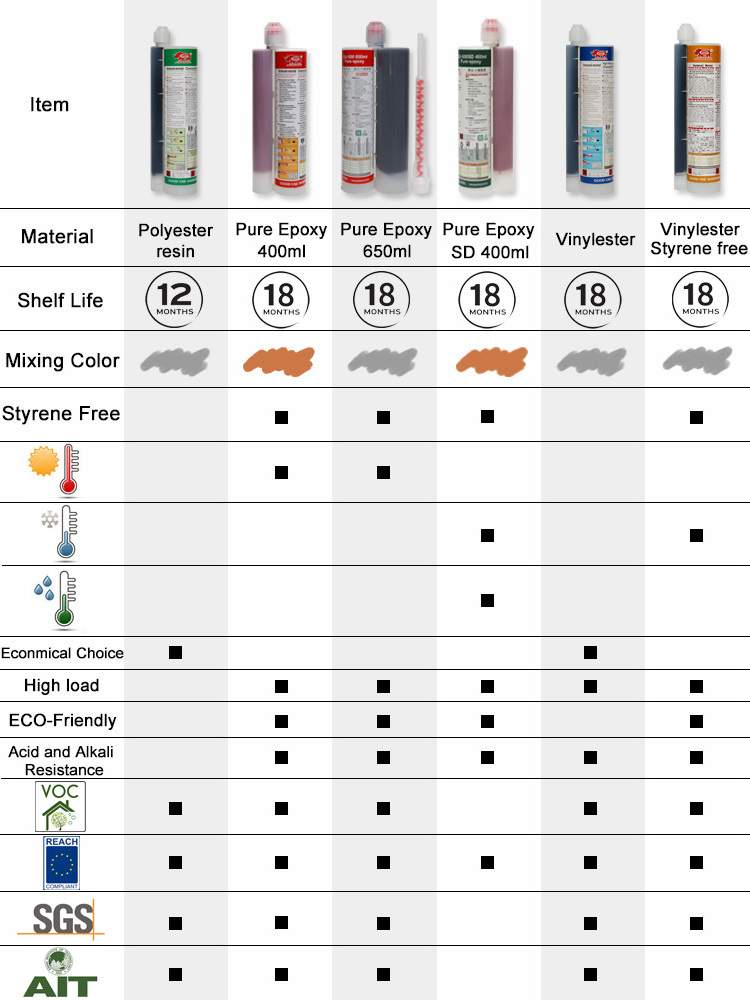

| PRODUCT NAME | High bonding injection epoxy adhesive for fixing in wet concrete |

| ITEM NO. |

GU-500SD |

| CAPACITY |

400ML(3:1) |

| GU-500SD 400ML is strongest in all chemical anchoring. Remarkable at cold weather, cracked concrete and water saturated holes. Ultimate performance for rebar connections, heavy anchoring on dry concrete, wet concrete, cracked and uncracked concrete. Advanced-formula pure epoxy adhesive is workable at wide temperature and crucial anchoring. Quality tested and approved by Germany lab. Non-sag allows for overhead and suspended ceiling application. There is also 585ml available in the range | |

Curing Time Table

| Temperature (C) | Gelling Time | Full Curing Time |

| 5~9 | 2 hr | 90 hr |

| 10~14 | 90 min | 64 hr |

| 15~19 | 45 min | 28 hr |

| 20~29 | 30 min | 18 hr |

| 30~39 | 20 min | 7 hr |

| 40 | 12 min | 5 hr |

After fully cured, wait for 24 hours before doing the pull out test. Kindly note the mortar must be conditioned at minimum of 15 degrees.

Hot Searches